Hello folks!

First post here. I picked up a Poulan 4218 off craigslist to refurbish. I can't get it started, though occasionally it does catch for a couple of cycles.

I bought a carb rebuild kit off Ebay and replaced the carb and the spark plug.

I've got fuel lines/fuel filter with the carb rebuild kit so I might try that even though I see fuel being delivered when I prime the saw.

Anyway at this point I'm kinda stumped. I'm a software guy by day so this is a new area for me. I'd appreciate any advice!

First post here. I picked up a Poulan 4218 off craigslist to refurbish. I can't get it started, though occasionally it does catch for a couple of cycles.

I bought a carb rebuild kit off Ebay and replaced the carb and the spark plug.

- Confirmed that there's spark.

- New fuel; confirm that it's getting to the cylinder (it sprays out when the spark plug is out and pull the starter).

- Confirm that the primer bulb is working (I see the fuel being pushed around).

- Air filter shouldn't be an issue; tried running it without one.

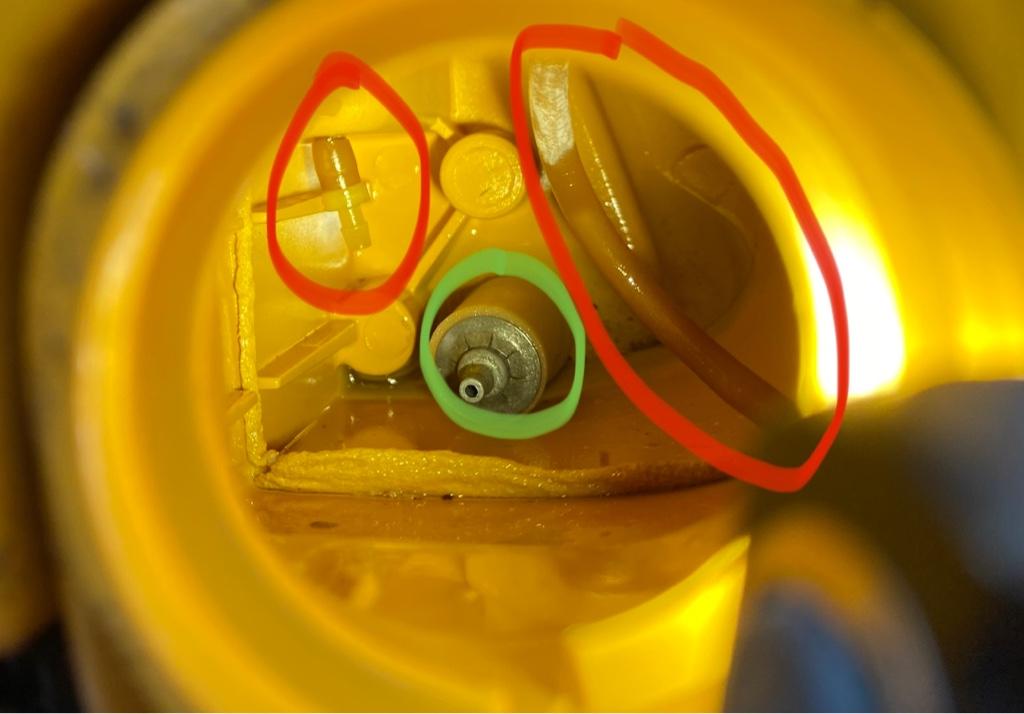

- Compression feels ok ("thumb gauge") and the piston isn't scored much from I can see.

I've got fuel lines/fuel filter with the carb rebuild kit so I might try that even though I see fuel being delivered when I prime the saw.

Anyway at this point I'm kinda stumped. I'm a software guy by day so this is a new area for me. I'd appreciate any advice!