Fuel being returned to the tank is about equal to what is being sucked out of the tank and into the carb. No pressure build up produced.Alright, I’ve taken the fuel out of the tank.

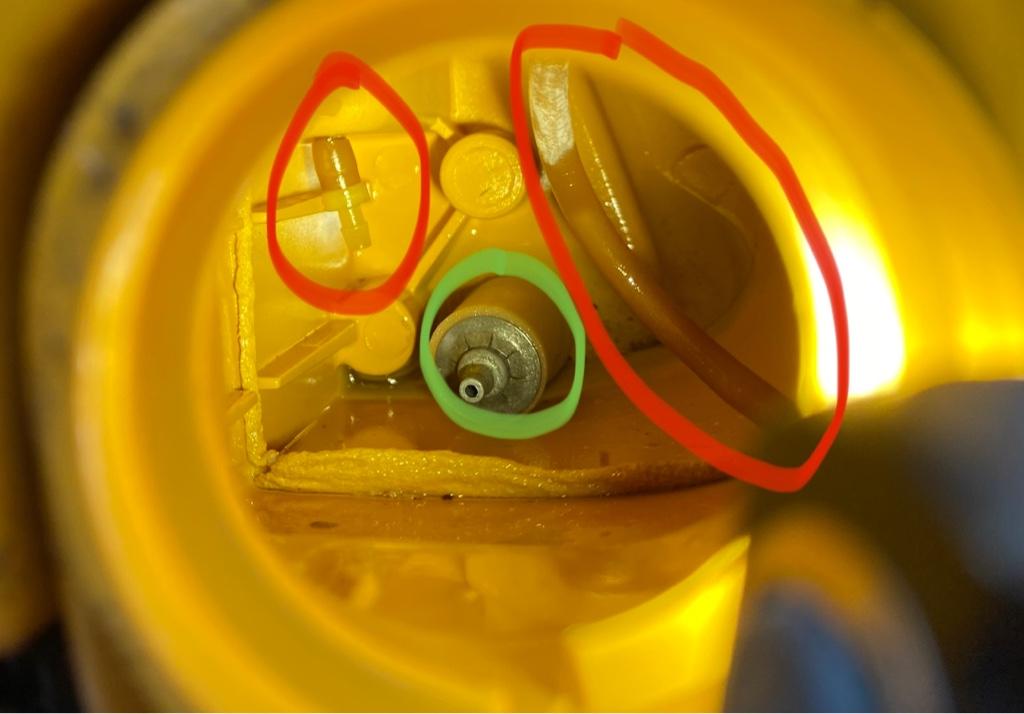

Does this look right? Obviously the filter needs to be reattached. The long line is from the primer, but I’m surprised how high the “main” line is. I guess it works but partially pressurizing the tank?

The two reds are two lines and the green is the filter.

Sent from my iPhone using Tapatalk

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Newbie refurbishing a Poulan 4218

- Thread starter dmitrym

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

So, here's the latest status:

- I drained the fuel completely (see above)

- reset all adjustment screws and started from scratch

1. I couldn't start the saw normally, I'm assuming it got flooded and I started with the "hold the throttle trick". after that it started fine

2. It's idling pretty well now, and I can throttle up, but it bogs down at the very top (see video)

I guess I'm getting there.

- I drained the fuel completely (see above)

- reset all adjustment screws and started from scratch

1. I couldn't start the saw normally, I'm assuming it got flooded and I started with the "hold the throttle trick". after that it started fine

2. It's idling pretty well now, and I can throttle up, but it bogs down at the very top (see video)

I guess I'm getting there.

What is your carb setting for the H screw? This is a stratto engine and the H screw is usually set 2.5 to 3 turns out and tuned from there by how it cuts and sounds. Most of these saws self-destruct because the H screw is set too lean and they can't be set properly by using a tach to set the WOT speed to some factory spec. If it idles steady and IF the H screw is properly adjusted and it still bogs when the trigger is pulled, the L screw usually has to be backed out a bit to give the low speed circuit more fuel to transfer to high speed...IS THE CHAIN BRAKE OFF? Lots of info here on strato engines, just do a search on "tuning a strato engine".

A word of caution. You can fry an engine by sunning it for very long with the top cover off, the cover is essential to concentrate the air flow through the cylinder fins in order to control the engine temp.

A word of caution. You can fry an engine by sunning it for very long with the top cover off, the cover is essential to concentrate the air flow through the cylinder fins in order to control the engine temp.

GoBigRed

ArboristSite Operative

How about simply tuning the saws carb while it’s running. It sounds rich as hell but videos sometimes don’t give you the right sound. Watch the video from Steve’s small engine repair on YouTube. He explains the the tuning process on a running saw and how to do it correctly and can explain it much better than all of us trying to type the way to do it. If the saw starts up and idles, you are there. My sons and I, 15 and 11, have rebuild and ported about half a dozen of these and I think you just need to keep it simple. Watch the video and tune it correctly. Then go cut something and have fun with the next

The video is excellent for adjusting the low speed and totally useless for setting the high speed, especially with a strato engine. Just trust the setting that the saw came with ??? Setting the H screw with a tack to some manufacturers number is risky at best and the worst way to set a strato engine. He would like you to believe that the H screw is just a speed screw and if you turn it in too far the engine will blow up because it's running too fast, doesn't talk about the importance of setting it to get the right mixture for good engine life.

GoBigRed

ArboristSite Operative

I don’t take it that way at all. You are seeing the problem and advising on your experience level, which is a very high level with years of trial and error experience, but when explaining things and giving info to new folks you need to make it simpler and break it down in to the basics. Once those basics are met and understood, then it’s time to bring on more advanced principles and concepts.The video is excellent for adjusting the low speed and totally useless for setting the high speed, especially with a strato engine. Just trust the setting that the saw came with ??? Setting the H screw with a tack to some manufacturers number is risky at best and the worst way to set a strato engine. He would like you to believe that the H screw is just a speed screw and if you turn it in too far the engine will blow up because it's running too fast, doesn't talk about the importance of setting it to get the right mixture for good engine life.

Give him some time, and then your knowledge and information will make him fly in the world of small engines. It’s not rocket science, but worrying about running a saw (a cheap poulan that wasn’t worth the gas to go pick it up) without the cover when he is just trying to get the darn thing running isn’t what he is looking for at this point. And setting the high jet at the factory setting is a great starting place when learning how to tune the circuit. Also, using at tach, if you have the manufacturers rpm specs is a great baseline, not dangerous. It simply gets someone going the right direction. Then, when someone gets more experience running a saw, they can get it in the wood and figure out what that machine really wants when tuning the high jet. Because as you know, that will change depending on so many factors such as bar length, chain type, wood type, and atmospherics.

crawl, walk, run. this video and a lot of the advice of others is at the crawl phase. Get him past crawl and walk, and then hit up folks with your detailed and valued info.

That’s all we are trying to do.

Then if you want, we can sit down over coffee and breakfast and talk about the finer points of the superior quality of the McCulloch chainsaw and how they are far superior to any others ever built in history. And I’ll gladly take your info how to get the damn tillitson on my 250 to run at peak performance

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$29.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

The problem is, making it too simple and suggesting that factory screw and tach setting are a good end point rather than just a starting point like the video did, might mean that the saw gets toasted before the owner has enough experience to properly tune it. Any newbie should be given instructions that will err on running the saw too rich which will allow the saw to survive until he learns how to tune better. Will not dispute the quality of the McCulloch even though my favorite is a Pioneer. Damn shame to see all the old good ones disappear.I don’t take it that way at all. You are seeing the problem and advising on your experience level, which is a very high level with years of trial and error experience, but when explaining things and giving info to new folks you need to make it simpler and break it down in to the basics. Once those basics are met and understood, then it’s time to bring on more advanced principles and concepts.

Give him some time, and then your knowledge and information will make him fly in the world of small engines. It’s not rocket science, but worrying about running a saw (a cheap poulan that wasn’t worth the gas to go pick it up) without the cover when he is just trying to get the darn thing running isn’t what he is looking for at this point. And setting the high jet at the factory setting is a great starting place when learning how to tune the circuit. Also, using at tach, if you have the manufacturers rpm specs is a great baseline, not dangerous. It simply gets someone going the right direction. Then, when someone gets more experience running a saw, they can get it in the wood and figure out what that machine really wants when tuning the high jet. Because as you know, that will change depending on so many factors such as bar length, chain type, wood type, and atmospherics.

crawl, walk, run. this video and a lot of the advice of others is at the crawl phase. Get him past crawl and walk, and then hit up folks with your detailed and valued info.

That’s all we are trying to do.

Then if you want, we can sit down over coffee and breakfast and talk about the finer points of the superior quality of the McCulloch chainsaw and how they are far superior to any others ever built in history. And I’ll gladly take your info how to get the damn tillitson on my 250 to run at peak performance

So, here's the latest status:

- I drained the fuel completely (see above)

- reset all adjustment screws and started from scratch

1. I couldn't start the saw normally, I'm assuming it got flooded and I started with the "hold the throttle trick". after that it started fine

2. It's idling pretty well now, and I can throttle up, but it bogs down at the very top (see video)

I guess I'm getting there.

In case there is any confusion about starting method, try this:

A cold 2-stroke engine will almost NEVER start with the throttle closed (idle position). When you pull the choke out on your saw, it bumps the ignition switch to the "on" position and, not only does it close the choke plate, but it partially opens the throttle and latches it open until the trigger is pulled. To start cold, pump the primer bulb until you can feel fuel being squished through it, pull the choke out and pull the engine over until it coughs, then push the choke in and pull a couple more times. DO NOT TOUCH THE TRIGGER, it will unlatch the throttle and you will be trying to start with a closed throttle. The saw should start and run very fast until you blip the throttle and return it to idle. MAKE SURE THE CHAIN BRAKE IS OFF. To avoid possible flooding, if it doesn't cough after 4 or 5 pulls push the choke in and try a few pulls with no choke.

When starting a hot saw, if it hasn't been shut off for more than a few minutes, most will restart with one or two pulls without touching the throttle. However, if it doesn't start with one or two pulls, it isn't going to start until the throttle is opened. With your saw, you pull the choke all the way out and then push it all the way back in, this will latch the throttle open in the fast idle position while leaving the choke open and the saw should start with a couple more pulls and run fast until the trigger is blipped.

GoBigRed

ArboristSite Operative

Ok. I just went back and rewatched that video. I see where you are coming from Old2stroke. I like Steve’s videos but that can be more confusing for someone new to tuning and running these things. I’m with you now

Patrick1903

ArboristSite Operative

It was an interesting process, I learned a lot.@dmitrym What ended up happening with your saw? I’m refurbing a 4218AVX now, so just curious.

I initially ordered a replacement carb from ebay, that was supposed to be compatible and by all appearance it was. But I couldn't get the saw started at all. On advice of an acquaintance arborist, I cannibalized the diaphragms and gaskets from the new carb into the original one. As well, the kit came with new fuel lines & filter so I swapped them in as well.

At this point, I fiddled with the hi/lo adjustments on the old carb too much and left the mixture way too rich to the point that fuel was spitting out of the carb. After fiddling with it for what must've been 8 hours I finally dialled it in and works just fine now. The idle is too low still so it bogs down sometime but I'm confident I can dial it in. I've got some wood with it already.

I didn't know anything about carbs or two stroke engines when I started so I've made tons of mistakes. Someone with a bit more knowledge I'm sure would've gotten it done much quicker.

Patrick1903

ArboristSite Operative

That’s great, glad you learned so much and have a useable saw. I cleaned carb and replaced diaphragms, gasket, inlet screen and needle. However, since I didn’t yet have the Poulan carb adjusting tool I wasn’t able to pull the hi/lo needles out to clean those passages. Reassembled everything (I had also replaced fuel lines/purge bulb) and saw started and idled ok. Wouldn’t rev smoothly; I could coax it to higher rev by feathering throttle. My hope is that those uncleaned hi/lo passages are an issue. And since crud could have moved around In carb after running it, I’ll dissemble (including hi/lo), clean carb, then retry. Plus I’ll be able to try to tune carb with the tool.It was an interesting process, I learned a lot.

There was a comment about drilling out the tank to make the fuel line bigger. That caught my eye bc the new line I put in there was much smaller than the purge lines, since the holes in tank were Different sizes. And a replacement fuel filter I bought was too big for the new fuel line (it was a generic fuel filter/purge bulb/fuel line kit from Home Depot, for various small engines). So I’m curious if it could be not getting enough fuel through the current line. (The old lines were so rotten it was hard to really compare the sizes. But I even struggled getting this new line through the hole in the tank. One thing at a time, I suppose.I’ll reclean carb and see what happens.

Once I’m confident it will run ok, I’ll get a new sprocket, and replacement bar and chain. (I’m thinking Oregon 16” combo from Tractor Supply and others). I just need to make sure it’s compatible. I also have the quick tensioner, so not sure if that affects bar compatibility. I may replace tensioner if that’s an issue with comparability. Thanks again and good luck.

That’s great, glad you learned so much and have a useable saw. I cleaned carb and replaced diaphragms, gasket, inlet screen and needle. However, since I didn’t yet have the Poulan carb adjusting tool I wasn’t able to pull the hi/lo needles out to clean those passages. Reassembled everything (I had also replaced fuel lines/purge bulb) and saw started and idled ok. Wouldn’t rev smoothly; I could coax it to higher rev by feathering throttle. My hope is that those uncleaned hi/lo passages are an issue. And since crud could have moved around In carb after running it, I’ll dissemble (including hi/lo), clean carb, then retry. Plus I’ll be able to try to tune carb with the tool.

There was a comment about drilling out the tank to make the fuel line bigger. That caught my eye bc the new line I put in there was much smaller than the purge lines, since the holes in tank were Different sizes. And a replacement fuel filter I bought was too big for the new fuel line (it was a generic fuel filter/purge bulb/fuel line kit from Home Depot, for various small engines). So I’m curious if it could be not getting enough fuel through the current line. (The old lines were so rotten it was hard to really compare the sizes. But I even struggled getting this new line through the hole in the tank. One thing at a time, I suppose.I’ll reclean carb and see what happens.

Once I’m confident it will run ok, I’ll get a new sprocket, and replacement bar and chain. (I’m thinking Oregon 16” combo from Tractor Supply and others). I just need to make sure it’s compatible. I also have the quick tensioner, so not sure if that affects bar compatibility. I may replace tensioner if that’s an issue with comparability. Thanks again and good luck.

Sounds like the hi/lo are likely the culprit. You should be able to take the screws out with just a set of pliers but of course the correct tool makes life easier.

In terms of fuel lines -- the skinny one on mine is the main feed and the thick one is the return. I saw someone on YouTube switch them with no ill effects. In fact, I accidentally had the return hooked up to the inlet and it was working just fine while the tank was completely full. I kept the lines like they were originally -- the skinny line is in, and the bigger diameter is the return and it works fine.

I think my saw is pretty old, I'm thinking mid 2000s, so no quick tensioner on mine. The tensioner is on the bar, but works just fine. If you google for the manual it should tell you what kinda bar/chain to use.

I'm going to have to replace the sprocket as well at some point it's pretty scored, but it working ok for now. Good luck!

If you are talking about exchanging the lines on the primer, there are problems. Mainly with the lines backwards you are asking the purge bulb to pump fuel directly from the fuel tank into the carbs' fuel chamber but the line from the bulb to the tank is terminated just inside the tank so, depending on the amount of fuel in the tank, you would be pumping fuel or just air into the carb. If you are pumping fuel, it is bypassing the control elements that determine how much fuel is in the fuel chamber and with more than a couple of pumps, you could flood the engine. Another problem is the check valves in the base of the bulb are now pointing in the wrong direction and could now allow air or an uncontrolled amount of fuel to be sucked into the fuel chamber. This could result in very inconsistent running. The purge bulb is there to suck fuel up an empty fuel line and fill the carb with fuel rather than just relying on the choke to do it, it was never meant to inject fuel directly into the engine.In terms of fuel lines -- the skinny one on mine is the main feed and the thick one is the return. I saw someone on YouTube switch them with no ill effects. In fact, I accidentally had the return hooked up to the inlet and it was working just fine while the tank was completely full. I kept the lines like they were originally -- the skinny line is in, and the bigger diameter is the return and it works fine.

If you are talking about exchanging the lines on the primer, there are problems. Mainly with the lines backwards you are asking the purge bulb to pump fuel directly from the fuel tank into the carbs' fuel chamber but the line from the bulb to the tank is terminated just inside the tank so, depending on the amount of fuel in the tank, you would be pumping fuel or just air into the carb. If you are pumping fuel, it is bypassing the control elements that determine how much fuel is in the fuel chamber and with more than a couple of pumps, you could flood the engine. Another problem is the check valves in the base of the bulb are now pointing in the wrong direction and could now allow air or an uncontrolled amount of fuel to be sucked into the fuel chamber. This could result in very inconsistent running. The purge bulb is there to suck fuel up an empty fuel line and fill the carb with fuel rather than just relying on the choke to do it, it was never meant to inject fuel directly into the engine.

I exchanged the lines on the carb -- the purge line went into the inlet on the carb and the fuel line went to the return. So the saw ran ok as long as the tank was full and would die immediately when fuel level dipped. I felt pretty dumb when I realized what I did.

What you're saying makes sense, not a great situation to be in.

You're not alone, when someone brings me a saw with a primer bulb, one of the first things I check is the plumbing to it. Many owners think that since it's called a "primer", it should be hooked up to inject fuel into the engine. The industry should have started labelling them "purge" and we might have fewer problems.I exchanged the lines on the carb -- the purge line went into the inlet on the carb and the fuel line went to the return. So the saw ran ok as long as the tank was full and would die immediately when fuel level dipped. I felt pretty dumb when I realized what I did.

What you're saying makes sense, not a great situation to be in.

I think the way this is written is somewhat confusingThe purge bulb is there to suck fuel up an empty fuel line and fill the carb with fuel rather than just relying on the choke to do it, it was never meant to inject fuel directly into the engine.

The purge bulb does draw fuel up from the tank and fill the carb but it does it by sucking gas thru the carb and shooting the excess back to the tank

My point being the purge bulb is plumbed into the return line to the tank, not on the fuel supply side.

Similar threads

- Replies

- 215

- Views

- 6K