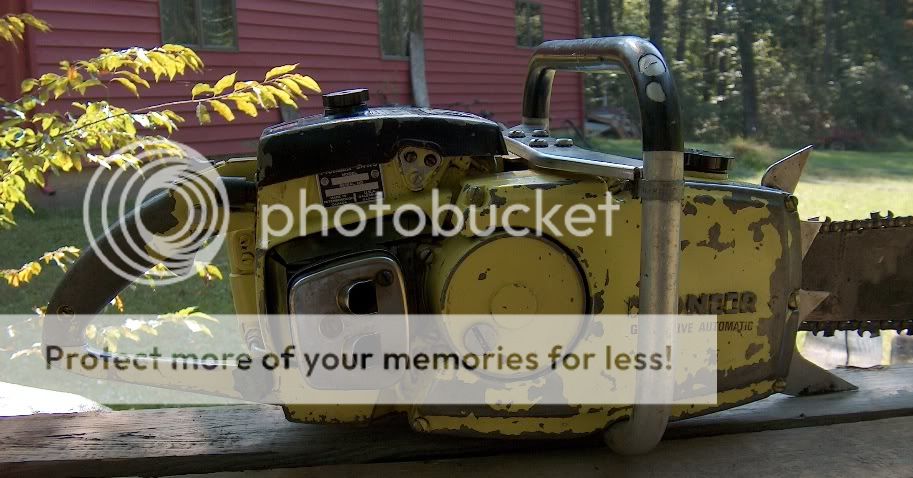

Been holding onto this for awhile. When I got the saw it rattled something fierce when I cranked it, ran poorly, and leaked gearcase oil all over the place. The chain would barely cut thru the air, like it was slipping badly. At one point, I flushed the gearcase, fired it up briefly, and thought I saw solvent pouring out of the muffler. I assumed worst and figured the crank/rod was bad among other things, put the saw aside and moved on.

Fast forward to 2 weeks ago, I finally decided to tear it down and find the problem. Found very quickly the crank/rod was in perfect shape along with the slug and jug. Also found the gearcase had detonated--a case screw backed out, broke the clutch hub and broke the oil pump shaft. The linings on the shoes were also completely gone. The oil leak was from the broken drum flopping around and wearing partially thru the gearcase cover.

I was able to accumulate all the necessary parts to restore to the 1560 perfect working order--rings, seals, clutch side bearing, NOS drum, NOS oiler shaft, fuel cap, gaskets. Even got ahold of a NOS chrome handle bracket to replace broken part and a NOS bar clamp. A parts 700G donated an excellent condition clutch. (The 700G is very, very locked up.) The shoes aren't the same as the 1560 but they fit the spider and the drum ID.

As far as the so-called rattle goes, turns out that was a loose starter pulley rattling against the cover. It was missing a nylon bushing. Fortunately, I had a good spare pulley. So much for making assumptions.

Now, the saw starts and runs perfectly with no rattles. The primer works, the auto and manual oilers work with aplomb. I patched damaged gearcase cover with JBweld inside and out--it's a non-structural part, so this seemed good enough. The fuel tank hides all the ugliness anyway.

This bar is 10-series Mac mount, running 3/8ths chain. The bar bolted right on, the oiler slot lines up dead on, the adjuster is in-line with the studs so no issue there.

Notice, I installed a 9-pin sprocket. I did this for 2 reasons--speed! and to take up the excess chain slack. Not sure the tail of the bar will support this setup.

Fast forward to 2 weeks ago, I finally decided to tear it down and find the problem. Found very quickly the crank/rod was in perfect shape along with the slug and jug. Also found the gearcase had detonated--a case screw backed out, broke the clutch hub and broke the oil pump shaft. The linings on the shoes were also completely gone. The oil leak was from the broken drum flopping around and wearing partially thru the gearcase cover.

I was able to accumulate all the necessary parts to restore to the 1560 perfect working order--rings, seals, clutch side bearing, NOS drum, NOS oiler shaft, fuel cap, gaskets. Even got ahold of a NOS chrome handle bracket to replace broken part and a NOS bar clamp. A parts 700G donated an excellent condition clutch. (The 700G is very, very locked up.) The shoes aren't the same as the 1560 but they fit the spider and the drum ID.

As far as the so-called rattle goes, turns out that was a loose starter pulley rattling against the cover. It was missing a nylon bushing. Fortunately, I had a good spare pulley. So much for making assumptions.

Now, the saw starts and runs perfectly with no rattles. The primer works, the auto and manual oilers work with aplomb. I patched damaged gearcase cover with JBweld inside and out--it's a non-structural part, so this seemed good enough. The fuel tank hides all the ugliness anyway.

This bar is 10-series Mac mount, running 3/8ths chain. The bar bolted right on, the oiler slot lines up dead on, the adjuster is in-line with the studs so no issue there.

Notice, I installed a 9-pin sprocket. I did this for 2 reasons--speed! and to take up the excess chain slack. Not sure the tail of the bar will support this setup.