You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Porting a MS660 w/BB Kit

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

gemniii

Addicted to ArboristSite

- Joined

- Aug 2, 2009

- Messages

- 1,502

- Reaction score

- 166

And I've got the oiler upgrade by some old guy with the handle THALL and a port job by some guy named blsnellingI'm sure an 660 will handle a 42" bar just fine, but that's really 084 territory and the stock oil output on the 660 would be lacking IMHO. With the oil pump upgrade and a good port job I'd say the 660 will rip pretty good with a 42" bar.

I'm tempted to swap my DP muffler on it also, but am concerned my standard jet may need to be swapped out.

I'm wanting to try a BB upgrade, but don't want to burn out what I've got

gemniii

Addicted to ArboristSite

- Joined

- Aug 2, 2009

- Messages

- 1,502

- Reaction score

- 166

Brad due U feel the ported 660 could handle the 42in bar day in day out, or would U opt for something bigger. It seems to me u would want something bigger for milling atleast.

I too would want something bigger for "day in day out" use of a 42" bar.

However remember in milling:

The entire bar is rarely used, w/ my Alaskan

So I've only got 32" in the cut MAX.MK-III Mill with 36" rails gives a maximum cut of 32"

Minimum bar requirement to achieve maximum cut: 42"

And I anticipate that will mostly be used when I've got to mill wood that's not straight, has "crotches", etc. so even then the full 32" will not be "in the cut".

What's impressive is when I go out to limb small bushes in my 1/4 acre suburban lot with my 660 w/ 42" bar. Neighbors KNOW I'm crazy!

wigglesworth

Booned

Bump.

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

Mastermind

Work Saw Specialist

I've got a brand new 066BB here that I'm porting, and thought that I'd share it with you guys. This is the first one I've seen since installing the prototype of this generation on my personal saw. These kits have a come a long ways.

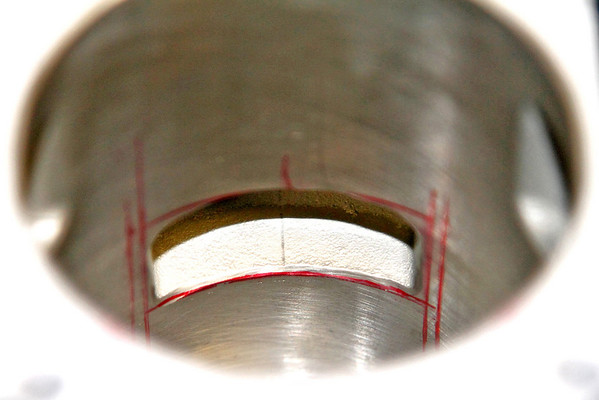

Let's start with the exhaust. The biggest problem I have with this cylinder is the exhaust port roof. It's still completely flat, with no curvature to it at all. This is not good for the rings. However, it does have a HUGE bevel on it, and will likely not be a problem. I'm going to massage this one a little, just to get a little curvature to it. I can't do much at all though, becaust the exhaust port timing is very high, at 96° ATDC. I would much rather see this at 100-105. 100 would be fine it weren't flat, but 105 would give me a little play room. As far as port width is concerned, it's already nearly as wide as the skirts will allow. My outer marks are the skirt edge, and the inner lines are where I'll be taking it to. Not a deal breaker here, but the biggest place for improvement in the cylinder.

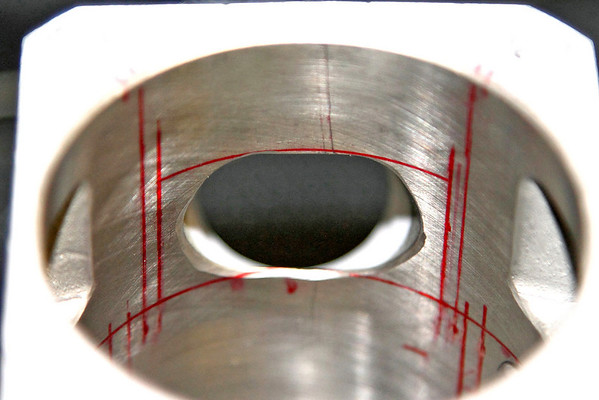

The shape of the intake isn't pretty, but isn't a concern at all. No rings travel across it. There is lots of room for improvement in port width here. Again, port timing is very agressive. It's an amazing 86° BTDC. However, that's how the one on my saw is, and it runs incredible and still idles good with good throttle response.

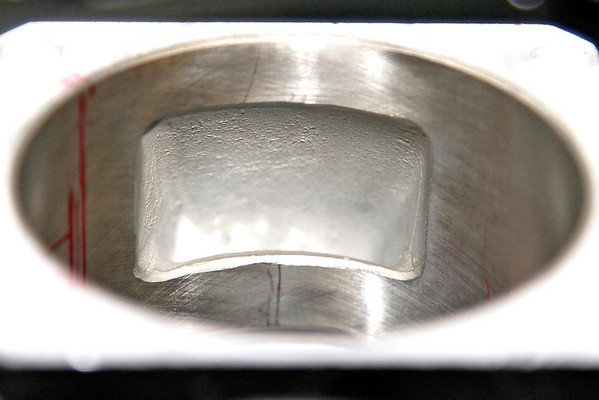

I see no issues with the transfers. The furthest line is the ring end. The closest is where I'll be taking the transfer to. You can't see it in this pic, but there's a HUGE bevel on these transfer, probably clost to .040" tall. The port timing is a 125°, giving me a blowdown of nearly 30°, so I'll be raising these to 120°, basically raising them the amount of the factory bevel.

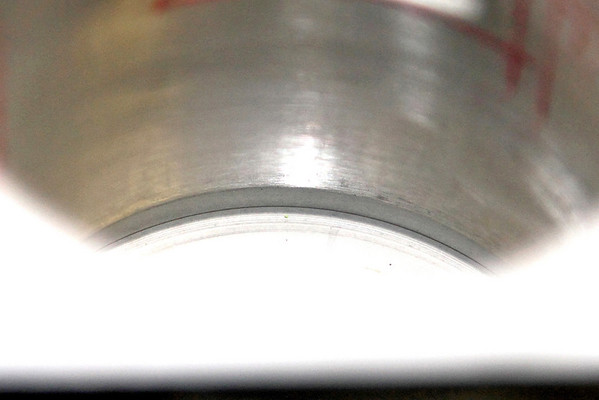

I won't be doing a popup on this saw, but if I were, there might be an issue here. It appears to me that the NiSi may not go to the top of the bore, by approxiamately .170". Subtract a squish of .020", and that's still .150". That will still have the rings riding onto this area .030". Hopefully this is simply unhone NiSi. I can feel no ridge whatsoever, so hopefully that's the case.

Bottom line, these kit's make a good replacement for a stock topend. With the aggressive port timing, it should make great power, even in unmodded form. Once ported, my 066 is a monster. I've had multiiple topends on it, and this was the first one that made me say wow. Hopefully this one will run the same. I'll post more as I go along.

bumped......

thomas1

sodium pentothal

- Joined

- May 2, 2010

- Messages

- 3,651

- Reaction score

- 1,092

My, what a tangled web we weave.

Tzed250

Addicted to ArboristSite

Snap

Mastermind

Work Saw Specialist

My, what a tangled web we weave.

If I'm reading this right he said they were great.

thomas1

sodium pentothal

- Joined

- May 2, 2010

- Messages

- 3,651

- Reaction score

- 1,092

If I'm reading this right he said they were great.

You have the eyes of a hawk.

Legs of an emu, but eyes of a hawk.

Mastermind

Work Saw Specialist

I will not use the piston or rings in these kits.

Randy, you're twisting the truth here and making it out to be what it is not. I pointed out the flaws in this kit, just like I did with the Meteor kits. Because of the problems in this kit and others, I have never been willing to port these cylinder for hire. I've had a few that I played with on my personal saws. Most all of our other builders will stand with me on that. Obviously, I've become less tolerant as time has progressed. I'm simply tired of the inferior product.

Last edited:

WidowMaker1

Addicted to ArboristSite

this chit makes for a good laugh

pappasteve

ArboristSite Operative

I've read through this post but didn't see what type of bb kit this is? How many different kits are there and which ones work good right out of the box? Just wanting a better wood cutting saw, not a everyday saw. I have a 066.

I've read through this post but didn't see what type of bb kit this is? How many different kits are there and which ones work good right out of the box? Just wanting a better wood cutting saw, not a everyday saw. I have a 066.

If looking for an AM kit, contact Mastermind. He will go through, clean it up, and make sure it's good to go. Otherwise, you just have to settle for the luck of the draw. Some are ok, some are not.

Similar threads

- Replies

- 5

- Views

- 463

- Replies

- 32

- Views

- 3K