Crofter

Addicted to ArboristSite

I wonder how many times they had to change the engine on those reeds during their 3 months continuous operation at 20,000 plus rpm?

Timberwolf, Yes, that was tried and it did work , but thats not what Deans claiming.The idea as I understand it is to use the high boost ports to shoot a bit of the outgoing charge (before full bleed down)down into the base and bump the base pressure up before the transfers open, then when the transfers open the extra pressure helps in getting the charge up into the cylinder adding to the super charging effect.

Piston ported engines work fine with pipes. Instead of the read valve controlling the intake the psiton skirt does. Both types close of the intake, but work in slightly differant ways. The read valvesallow for more midrange, and low end power becase they reduce spitback out the exhaust and rough running at low speed due to excessing intake timing. The actually make slightly less power than a piston port though as reed are another restriction to air flow.This effect is slight.A reed valve is needed to prevent this pressure wave from pushing the charge back into the carb. Thus, with a good expansion chamber and reed valve you can get a positively charged cylinder yeilding great power.

On a very mildy tuned non-expansion chamber equiped two stroke engine a reed valve is not really needed I suppose, but on a high performance two stroke engine you'll have difficulty getting top power out of it without a reed valve.

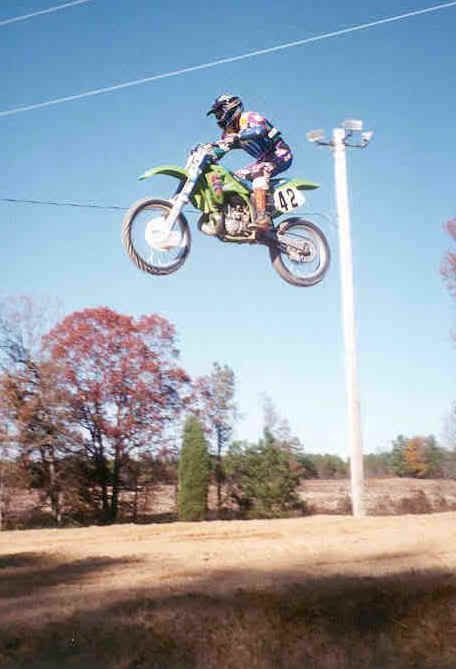

bwalker said:The average pro racer in the 250 class is only at full throttle about 30% of the time. This figure was related to me by a man the wrenched for several of the low level factory teems(Noleen, Plano Honda, ETC).

I would never go over a year on a 250cc bike used for MX. Its not the wear that will bite you it the service limit of the parts.

I have at least 10 saws here that need new reed valves. 4 of them HVA'sbugfart said:A set of aluminum reed valves in an older saw will outlast us all. You can make new ones pretty easilly I bet. Never even heard of one going bad before this discussion.

Crap lodged inside, yes. Reed failure? Total ingorance to it.

Thanks for getting me all freaking paranoid.

The service limit for a 250 if memory serves me correct is about 25 hours. If you road it for a year you surley exceded the service limit.After a solid year of riding/racing none of the top end parts on any of my 250cc bikes have been anywhere near the service limit.