TMAR

ArboristSite Lurker

i dont suppose anyone would be able to suggest some good wheels to use for running along the rails? im having trouble finding any decent ones

That depends on what you are using for the rails.

i dont suppose anyone would be able to suggest some good wheels to use for running along the rails? im having trouble finding any decent ones

done a little more research, and decided on V groove gate wheels running on angle, should be a smooth method

hey jan the band length isn't that important. there's plenty of blade suppliers that can make bands to any length. the mill i built uses longer bands (b/c i found some larger wheels) but most mills this size use somewhere around 158" i believe. gene never produced dimensioned drawings but that's not that important either. look close at his pics and you can figure it out.

Thank you thats help me alot but the 158" what is that in CM (158 * 2,5=) is it like that or ? but else i thank you alot

hello gene can a 5 kw with 2900 rpm do it as well like a honda engine, can i get the same NM on a elektrick motor Jan

Thanks for the infomation Dennis, I plan on building the small mill the one in the video. I get about six feet of snow pack, so need to store the mill inside, and don't have lot room. I was going to build a chain sawmill because all the bandsaw mills I had seen were too big. I was delighted when I found Gene's small mill on you tube, just what I have been looking for, and when video started, he not pushing hard, its working as well as any of the production mills on youtube. I could tell right away Gene had his design optimize way better then any of other designs I had look at.

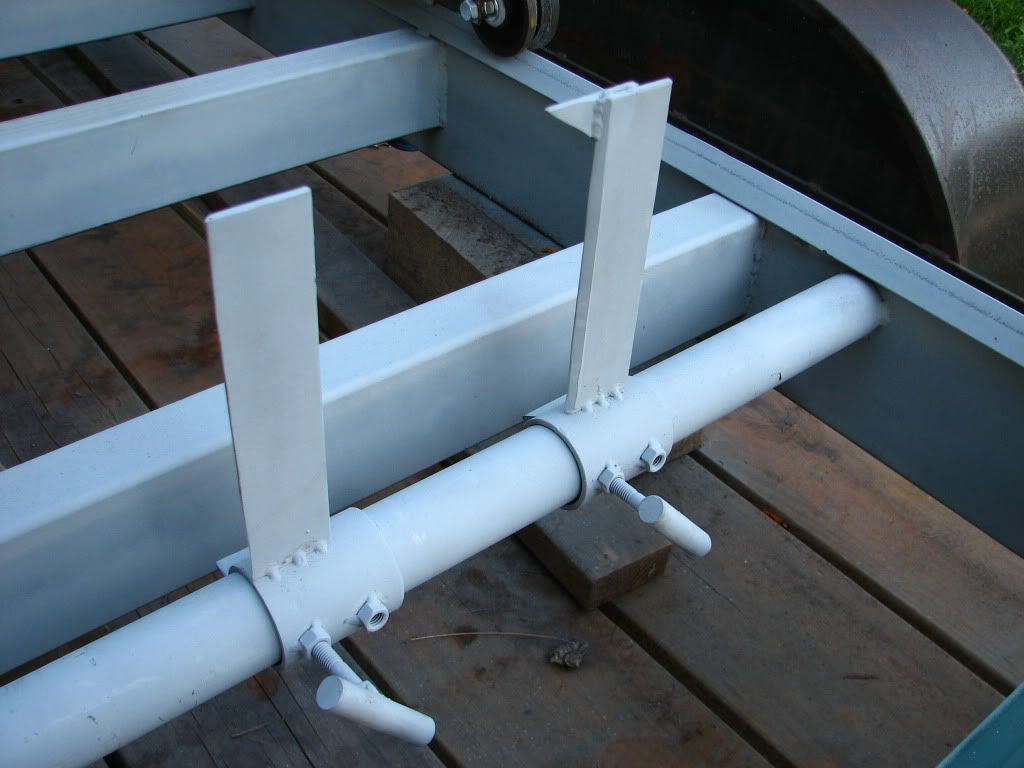

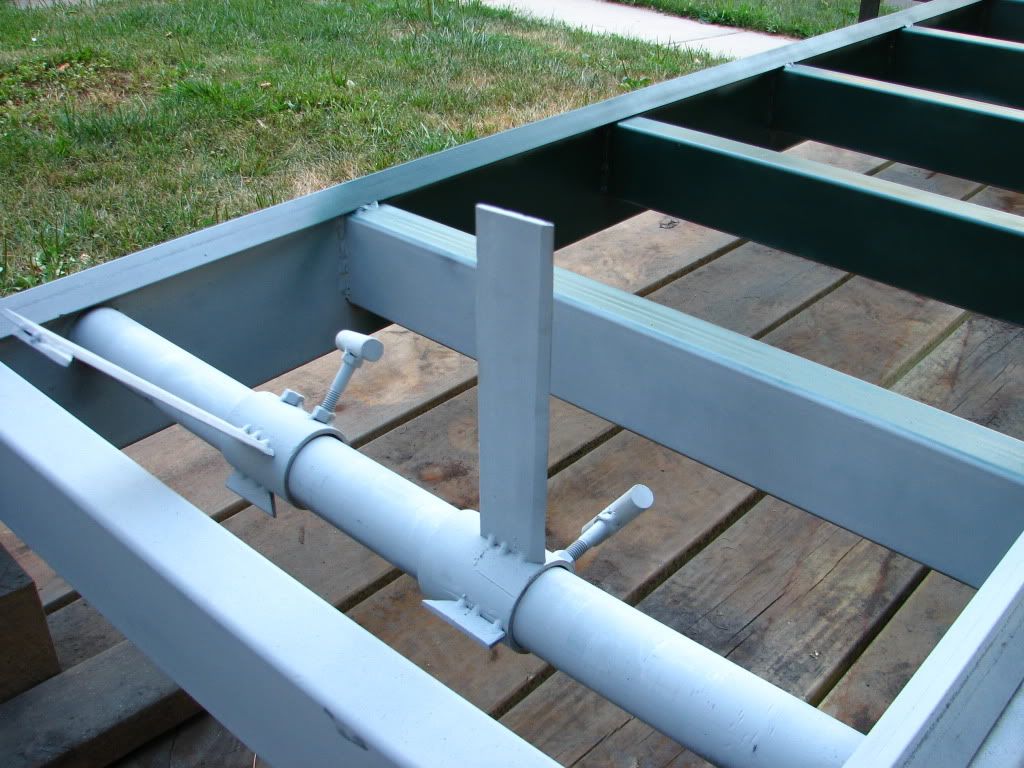

The small size will work good for me, what does'nt fit the mill is less fire wood i'll have to buy. the photos are great, I setup a slide show, and been studing the details of Gene's and Rail-o-matic mills, for about hour a night last few nights, and I think I get. The height of carriage, looks about 36", and wall thickness looks like 1/8" which is thinner than thought it would be. The wheel bar looks 2x2 .250 wall in the pic of the small mill. The feet I say 28" 2 x 3 x 1/8 angel which is also thin. Gene welds up his carriage post so the width is narrower at the bottom, snap on fit at the feet, I would like to know how much less he jigs up bottom than the top. If I get it, this snap on fit reduces head shake and makes for a solid carriage. Gene has done the R&D , I understand from reading his post that he has a few pages of plans drawn up for the small mill. I would like to get a copy, it will save time and optimize my build.

I have sent santa after the axles, wheels, bearings, pulleys, clutch, and engine. I have most of the steel for carriage in the shop, so santa will only have get rails and few odds & ends. Dennis DRO great idea, they come way down in price last few years.

Gene If I could get your phone # and may be a copy of your plans for the small mill. I would appreciate it, I don't want change any part of your design, its the small details that make it work so well. i just want to copy copy copy!

Thanks

[email protected]

707-365-8616

Enter your email address to join: