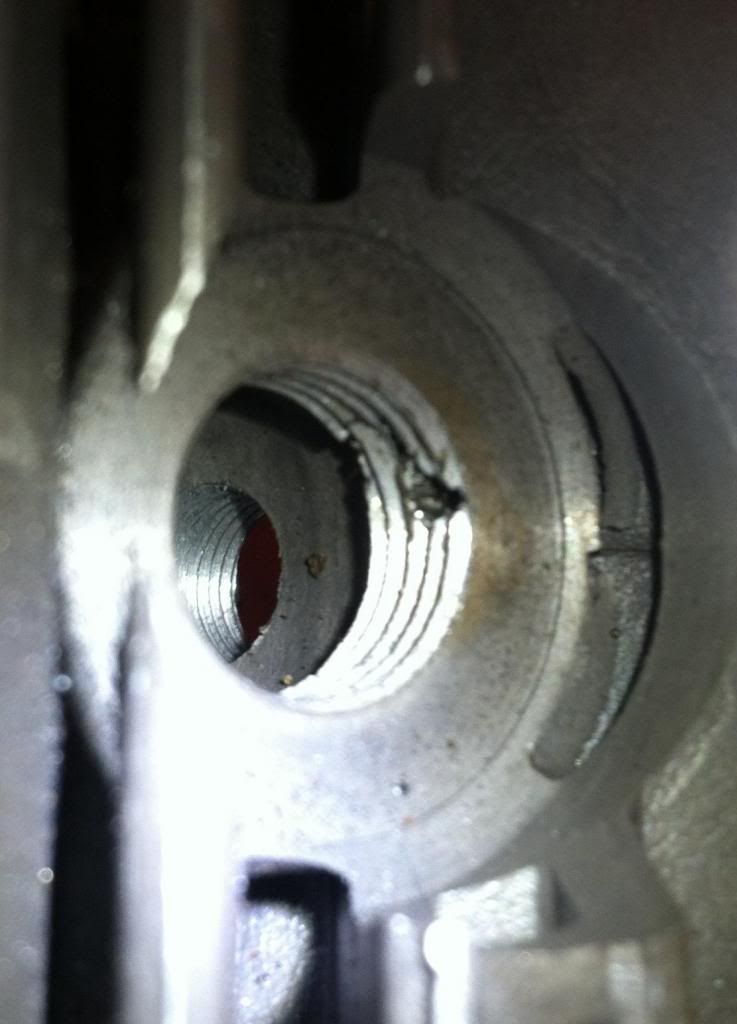

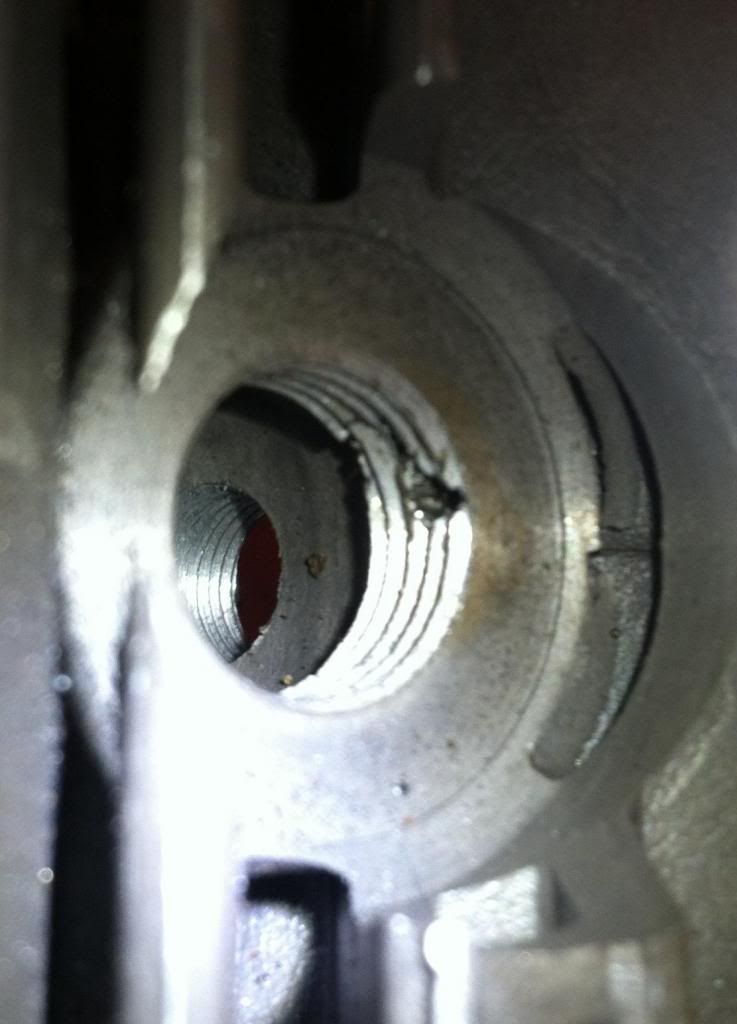

Combustion chamber, Has a nice flat squish band with a good curve right into a nicely shaped combustion camber center. Does not appear to be completely over cast with chrome an has an overall nice tight appearance which is what you want to see. Once seated on the saw you'll want 0.020 squish and Justin will comment on this later as well as the initial compression numbers.

Ok so here is the update:

0.017 thick base gasket

0.012 squish w/out base gasket

0.029 squish band total

Compression was at 140psi at 0.029 squish which could be improved with several things very simple things. The first is to put a plug in the decomp hole. Decomp buttons are not necessary on most 70cc and smaller saws (unless you have severe shoulder or wrist problems). Decomp valves are designed to bleed off compression from the combustion chamber for easier starts, and the valve closes once the saw fires. The problem is that they tend to leak when the valve has a bad sealing ring or when the valve seat itself is compromised (you wont know this unless you can leak check the saw). Do yourself a favor and get a plug and close it off! It's the only way to ensure your top end isn't losing power (and compression) through the decomp valve.

To make it simple:

Replace this...

http://www.weedeaterman.com/product_p/h11280.htm

with this...

http://www.weedeaterman.com/product_p/t635701.htm

Caber rings and an adjusted base gasket are the other way to increase compression of a bolt on kit. Instructions below...

Squish band:

Definition- The area between the piston and inside top (roof) of cylinder. Rule of thumb is that you want 0.020'' average between 3-4 measurements. Insert some 0.050 electrical soldier into the spark plug hole and across the cylinder wall. Roll the engine over slowly to crush the soldier between the cylinder roof and piston (ie: squish band). Remove and measure with a dial or digital caliper ($8 @ Harbor Freight). This measures the distance you have left at TDC (top dead center), and ideal work saw will have and average of 0.019-0.022 in. Obviously the 0.028 squish on this cylinder kit is not "ideal" but can be adjusted by changing the thickness of the base gasket. The base gasket (on this saw) to 0.008 to make a perfect 0.020" squish band. This will decrease the combustion camber 0.009 thickness x diameter of the bore (44mm-44.7mm diameter in this case). The decrease in combustion camber area will increase the compression ratio, and thus increases the pounds per square inch (psi- rating). I would guess that an increase of 10-15lbs is about common with Caber rings and an ideal squish band.

NOTE: check your own numbers!

Aftermarket kits will not be 100% the same numbers. Some squish bands can be higher or lower depending on the individual kit. You may get lucky and be able to delete the base gasket and use some yamabond sealant on the bottom of the cylinder to get that 0.018-0.020 in squish band. It is your own responsibility to measure your own numbers. Neither Weedeaterman nor myself will take responsibility for cylinders ruined by your own negligence. That being said if you are not sure of what to do after my instructions just install with the base gasket.

Also a secondary effect of decreasing the base gasket width is the lowering of the overall cylinder height. This will lower the roof of the exhaust outlet (ie: lower exhaust timing) and increase the torque produced by a hair. It will probably not be noticeable to the lay user but just wanted to add it in as extra learning content for readers. You will read later what Justin's doing to the intake and exhaust timing to increase power.

Hutzl kit:

Didn't even bother with a pic but it was completely overcast with aluminum and didn't have as good a shape to the combustion chamber toward the middle. I will try to get pics and add later...