Carb Cleaner in Eye, Duh!

I can't say I wasn't warned!

Hopefully some others will learn from my carelessness:

I

Strongly recommend a full face shield and safety goggles while using pressurized carb cleaner. I had a scare, thankfully my eye is OK.

Watch your eyes... fluid can squirt out at you if you don't know what you are doing...

Or even if you think you know what your doing!!![/QUOTE]

Lakeside53 said:

so true....nothing quite like carb cleaner in the eye

While cleaning the outside of the carb prior to disassembly, I had made a few sprays and realized I needed to be careful. I still managed to underestimate the pressure of the carb cleaner, and while spraying a recessed area of the outside of the carb I got a good shot of it in the left eye and even some in the right eye.

I immediately flushed both eyes out under continual cold/luke-warm water for 15 minutes (as stated on container), and spent more time flushing the left eye.

After about 7 minutes of flushing I checked in the mirror and noticed a portion of cloudiness on the blue iris area of the eye, and a small portion of the black retina had "disappeared" (for lack of a better term). My vision was a bit blurry in the left eye and I decided not to take chances, so it was a trip to the ER at 11:00 PM.

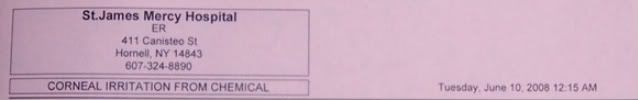

On the way down my vision started to improve ( a huge relief, wife was driving). They did more flushing of the eye at the ER and a check for damage. The doc determined that it was a corneal irritation from the chemical and the eye would recover quickly and easily, but still required a follow up with the ophthalmologist (which I'm hoping will be a quick, routine visit) By the time I left the ER the cloudiness of the blue iris was gone, and the retina appeared complete.

At first, Poison Control said that an ER trip wasn't necessary, then we told them about the blurred vision and they advised that I go. The container of STP carb cleaner says to see immediately see a physician as well. I know alot of folks wouldn't have made the trip, but when it comes to my vision, I chose to follow the advised procedure.

This was a temporary delay to the project (among many other delays), but with safety in mind I'll hopefully be disassembling tonight.

To all the guys that have helped so far on this thread; Thanks! I'm embarrassed not to have been more careful and heed the warnings, but I wanted to post this for other people's safety.

Bill