Also if the oil delivery tube isnt seated tightly in the case it will leak past the hose and back to the clutch housing. Verify the oil tube is tight in the case.

Yes no way the brass bushing at the outlet should have been loose. That hose is thermoplastic and requires heat just to get that brass outlet and/or pump nipple installed.

Also try this. Mount the bar w/or without the metal chain catcher plate using only the nuts and some washers on bar (no clutch cover), and no chain.

Start the saw and see where the oil is puking from; Bar groove (like it should), between bar/case, under pump cover.

I'll bet the output line is loose or cracked if there is not a leak at the pump itself.

You could also do this test without the cover for the clutch installed, wear some safety glasses.

Also, does saw have OEM thermoplastic outlet hose w/metal coil insert, or a jury rigged substitute?

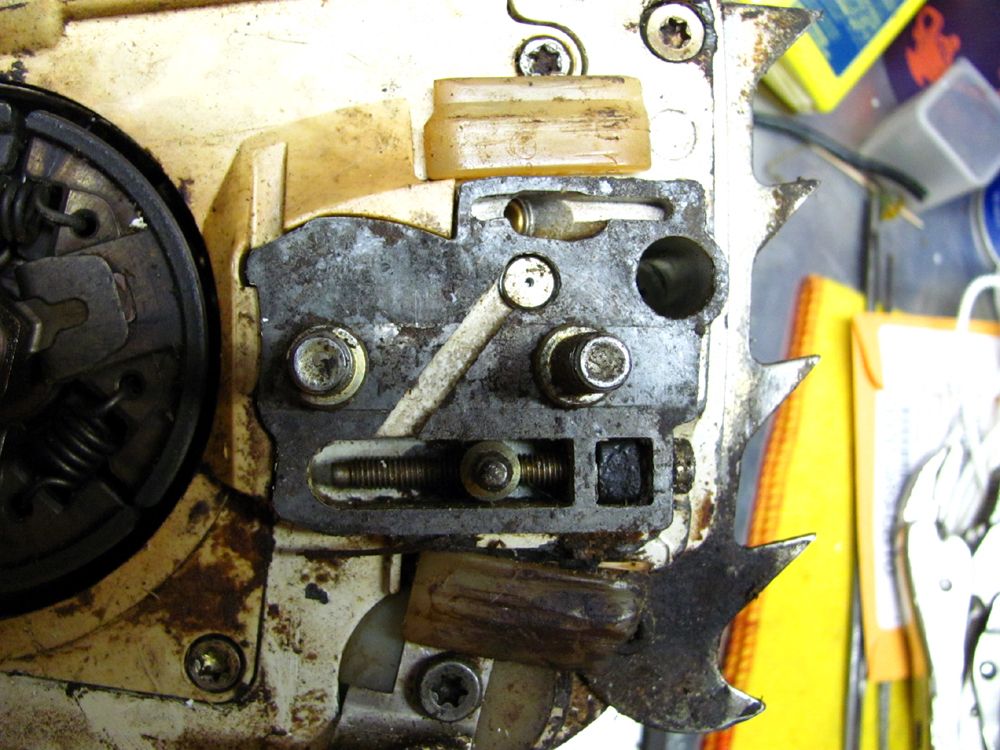

See the pics I posted.

The oil pump kit shows the hose cut to length (74mm) with bass nipple already installed (using heat).

Oil hose installed is the above hose seated from

outside of case

oil pump connected is after inserting spring coil, then heating pump end of hose and working over pump outlet nipple

Oil pump outlet is just the hole in the case, no hose.

The above pics are from a 036 build but apply to 034 saws too.

Note:

You can connect pump to hose first (using heat), insert coil and work through case outlet, heat and install brass bushing to outlet end of hose, then tap hose outlet back into case (backwards of what I did).

Hope this helps,

MP