treemandan

Tree Freak

Some more interest has inspired another post on this. I tried to start a thread in another forum about things like this but it didn't take.

And I will be right back.

And I will be right back.

......be sure to check it for bees first!

One of the best things I added to my truck was a front receiver. Have one on my mini-skid as well.

As Tony the Tiger would say....... "They're Great!!!!!"

I love the front receiver, it makes it so easy to reposition a chipper in a back yard.

That rake on front looks neat, could you build in a tensioning spring so you could backdrag with it?

Sorry boys, I just can't see the point##

Not saying it doesn't exist, it's just that I've never seen a location that I couldn't back into## Providing, of course, that it was possible to go in front first, too##

If it is sooo tight that you need front steer only to access that point, then you will surely have just as much trouble backing out with your front mount receiver as you would backing in with a conventional setup##

I have always operated my vehicles with this philosophy: If you can't back it in, then you darn sure better not drive in forwards## I've never been stuck in a spot that I was able to back in to, but I have seen situations that were impossible to back out of##

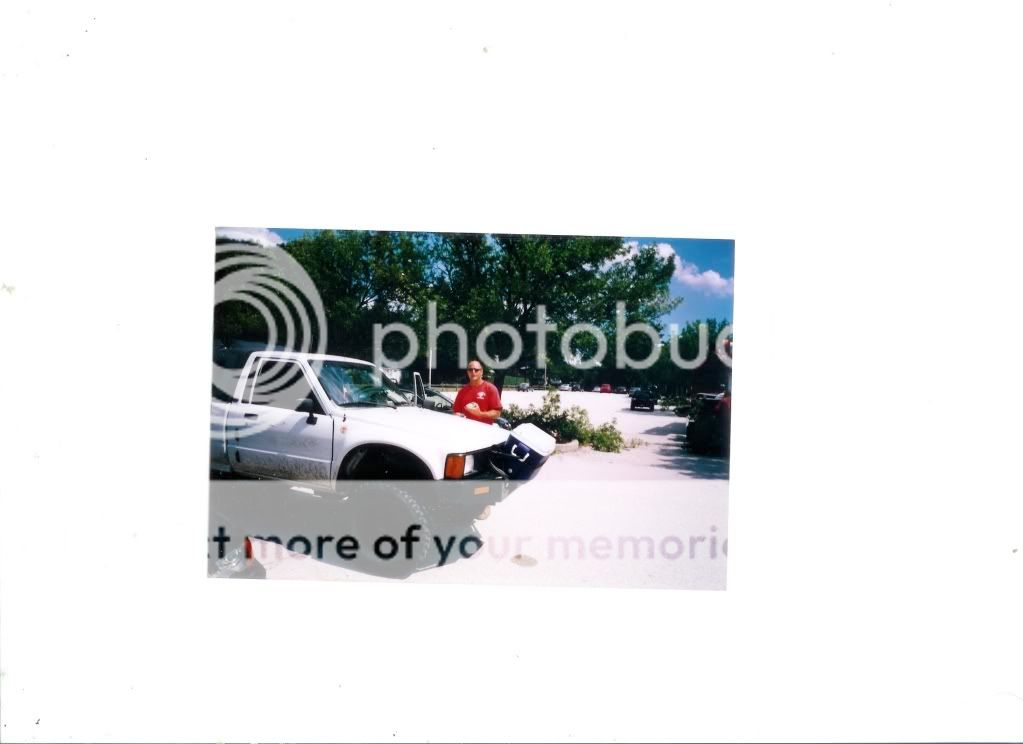

Never tried the front receiver, yet. Having always been an off-roader, it seemed only natural to me to try and get the chipper in the most unusual places. I've had this truck for 13 years and it has amazing capability with a rebuilt 350, TH400, 14-Bolt rear with Detroit Locker, and custom bed. I'm still dreaming of putting a solid 60 or 14 in the front, but I have to say the 10 bolt IFS has done amazing things over the years. I seem to be able to get our BC1500, 7000lbs., just about anywhere.

This was a right-of-way clearing job, maybe only better served with a tracked chipper.

View attachment 167997

) but we are going in! YEEFNHAA and we're gonna get dirty. No, we ain't going break nothing and I will get pissed if anybody tries.

) but we are going in! YEEFNHAA and we're gonna get dirty. No, we ain't going break nothing and I will get pissed if anybody tries.Enter your email address to join: