BigOakAdot

ArboristSite newb

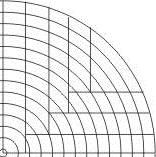

I have a 30" plus red oak tree down in my backyard. My question is when do you decide to quarter-saw wood? Do people quarter-saw all species of wood?

I personally like the natural edge look, but figure I have so much oak down I should look into quarter sawn oak.

I know it's more stable to quarter saw but I'm curious as to what is the deciding factor for you guys. Size or use of finished product? I plan on building tables and stuff with my wood. Thanks!

BOA

I personally like the natural edge look, but figure I have so much oak down I should look into quarter sawn oak.

I know it's more stable to quarter saw but I'm curious as to what is the deciding factor for you guys. Size or use of finished product? I plan on building tables and stuff with my wood. Thanks!

BOA