You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

To quarter saw or not?

- Thread starter BigOakAdot

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

If you plan to CSM the logs in place, I would very strongly recommend that you flitch saw. It is by far the easiest, fastest and most economical method of sawing. It will also give you the best variety of a qs, rift and flat / cathedral grains, and the most wide boards. If you can get the logs transported to where you could have portable bandmill come in, or to a local mill, then you can choose between flitch, cant, grade or quarter sawing. Again, I recommend flitch or cant for the best variety of grain patterns and most economical milling, unless you absolutely have a plan that requires qs.

P.S. it's gonna take a long time, a lot of gas and a lot of wear and tear on your 660 to CSM those logs. Probably wind up cheaper ($150-250) and faster (2-3 hrs. depending on setup and experience of the sawyer) if you can get a portable bandmiller out there. Might be able to help you skid the logs too for a small fee.

BigOakAdot

ArboristSite newb

Yeah maybe I should look into that. I'm not familiar with those other kinds of milling techniques. The pic above I would assume is an example of quarter sawn... What in the world is "flitch sawing"?

Flitch sawing just means cutting through the log bark-to-bark with parallel

cuts.http://www.horizonevolutions.com/specialty-lumber/horizon-cutting-techniques.html

cuts.http://www.horizonevolutions.com/specialty-lumber/horizon-cutting-techniques.html

$79.99

$89.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$22.95

$24.99

Weaver Leather (08-98225-BO Arborist Bungee Chain Saw Strap, Orange - 30"

Greener-Garden

$14.99

$19.99

Extendable Pole Saw Branch Trimmer Pruner Head for Tree Trimming Pruning

FENGLICNSAOMV

$225.39

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express-Shipping-24hr ✅

$59.99 ($0.40 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

BigOakAdot

ArboristSite newb

Yeah I'm sticking to flat sawing for nkw since I have nothing but man power. And yes I paint all of my green logs with layex based paint... Seems to help with the cracking.

Dave Boyt

ArboristSite Guru

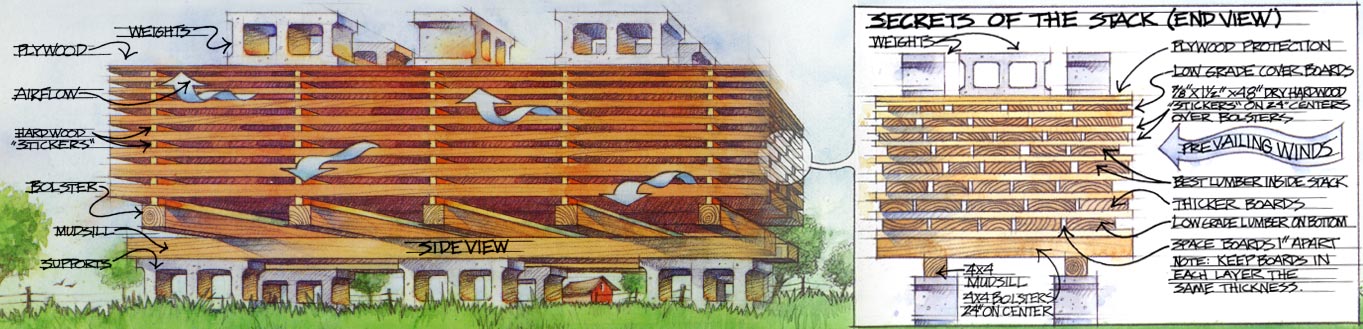

I think Anchorseal is definitely worth the price, especially on more expensive wood, like cherry & walnut. I end coat the log before milling-- as soon after felling as possible, as the drying through the end of the log starts as soon as the wood fibers are exposed. Cgraham1, that drying illustration is great! Did you draw that?

My stacks look very similar to the sketches above with 2 differences. 1. I put more weight on top, especially over the ENDS of the boards. 2. I go ahead and put corrugated plastic roofing sheets over the top with a 8-12" overhang to keep the sun and rain off, also if it's too warm and dry, I can wrap the stack in burlap.

P.S. All ends are anchor sealed. It dries clear.

P.S. All ends are anchor sealed. It dries clear.

BigOakAdot

ArboristSite newb

Stack looks great. I just realized you're the same person who was looking to sell white oak that you had milled. What did it cost you to mill all that freaking wood? Oh, and what part of PA are you from?

BigOakAdot

ArboristSite newb

What do you guys use for stickers? I have pallets and scrap wood that I cut with the circular saw but do you guys buy wood that's pre cut? I know 1x1 is a good size...

Sawyer Rob

Addicted to ArboristSite

Just so you guys know, cement blocks are a LOT stronger if you turn them the way they are ment to be built with... Then, you can use less of them in your stacks and end up the same strength.

As for stickers, I mill them out of low grade top logs, it's fast and I can turn out a couple hundred in a fairly short time,

Then I stack them for drying, as you should ALWAYS use DRY stickers,

Lastly, i've found that Anchorseal easily beats out paint in my test, I no longer waste any time/money on paint... Melted candle wax works good too, if you only have a log or two...

SR

As for stickers, I mill them out of low grade top logs, it's fast and I can turn out a couple hundred in a fairly short time,

Then I stack them for drying, as you should ALWAYS use DRY stickers,

Lastly, i've found that Anchorseal easily beats out paint in my test, I no longer waste any time/money on paint... Melted candle wax works good too, if you only have a log or two...

SR

BigOakAdot

ArboristSite newb

Looks perfect but unfortunately I don't have that option because I only own a cs mill. I don't even own a band saw or table saw lol  I will be looking to get into getting a table saw and stuff but as of now SOL

I will be looking to get into getting a table saw and stuff but as of now SOL

No. I just saw that somewhere and thought it was cool.I think Anchorseal is definitely worth the price, especially on more expensive wood, like cherry & walnut. I end coat the log before milling-- as soon after felling as possible, as the drying through the end of the log starts as soon as the wood fibers are exposed. Cgraham1, that drying illustration is great! Did you draw that?

Thanks for the info on the blocks.Just so you guys know, cement blocks are a LOT stronger if you turn them the way they are ment to be built with... Then, you can use less of them in your stacks and end up the same strength.

As for stickers, I mill them out of low grade top logs, it's fast and I can turn out a couple hundred in a fairly short time,

Then I stack them for drying, as you should ALWAYS use DRY stickers,

Lastly, i've found that Anchorseal easily beats out paint in my test, I no longer waste any time/money on paint... Melted candle wax works good too, if youly have a log or two...

SR

I don't own any kind of mill, so I get 1"x3"x8' lathe, split it down the middle into 3/4"x1 1/4" and cut in half to 4' lengths. Goes pretty quick on my bandsaw. I learned this from Groff&Groff Lumber down in Quarryville.

I'm in Palmyra PA 17078

It cost me about $225 to get the oak milled quartersawn. It would have easily been less than $150 flatsawn.

More fun milling and drying pictures. 2 Red oaks, 1250 bd-ft of 4/4. About 1K of it became about 850 sq-ft of flooring in our house.

P.S. The blocks didn't crush with >6 tons of green lumber on them. However, I will use them the "right" way next time.

P.S. The blocks didn't crush with >6 tons of green lumber on them. However, I will use them the "right" way next time.

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 24

- Views

- 2K