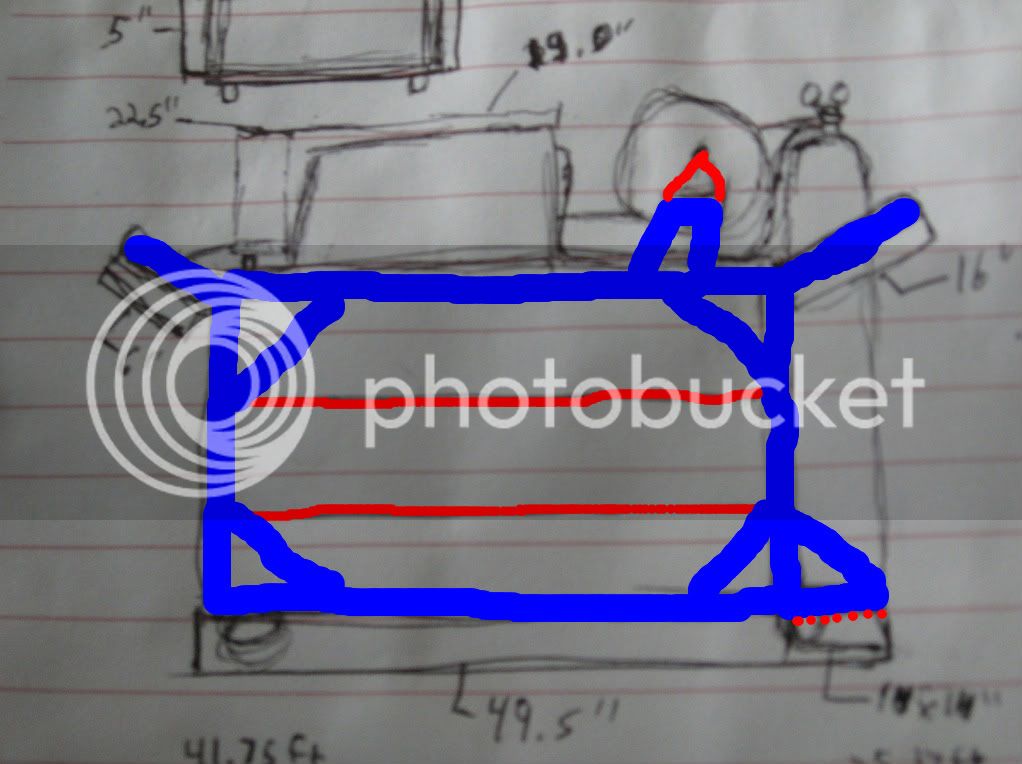

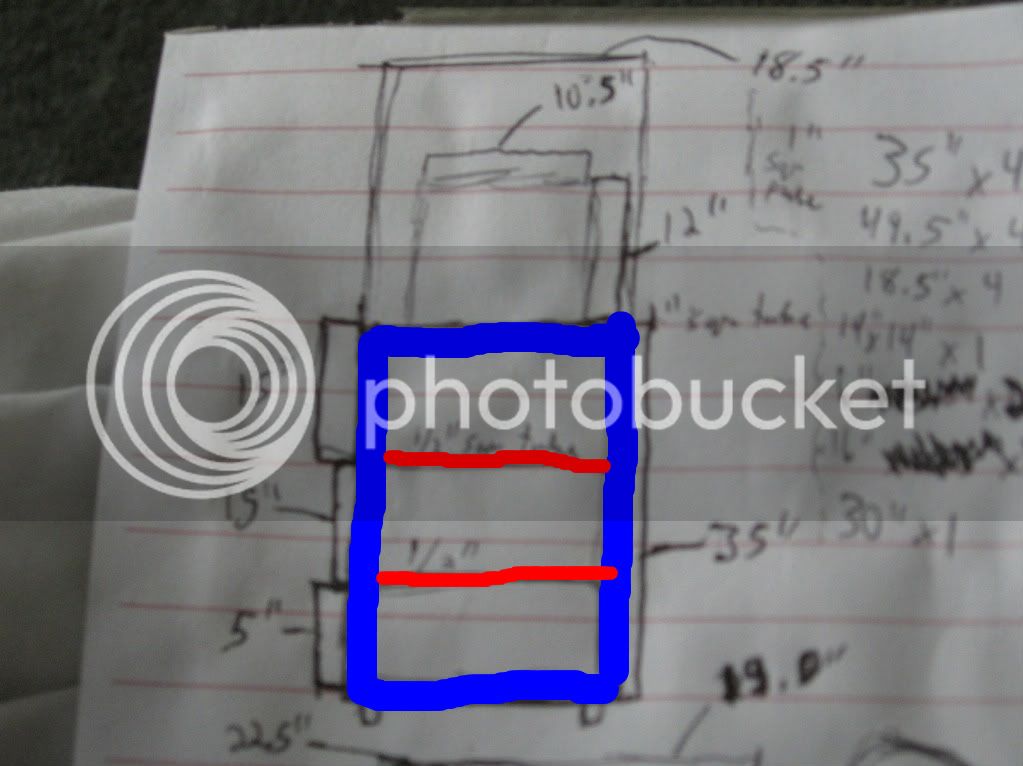

Here are two pics showing my draft drawing of the welding cart I plan to build.

I made provisions for a shielding gas tank, 33+ pound spools, and all casters will swivel. (hate trying to wiggle stuff around to make it go into a tight spot...)

The casters are from some heavy duty shelves, made by Gorilla. Thing is we don't want the casters on the shelves, so I plan to use them. Supposed 500 pound capacity for a set of four. If things warrant, I will use all eight casters that we have from the two shelves.

I will use 1" square tubing for all of the outside perimeter frame pieces, and the tank holding base, as well as the supports for the tank base. I also will have supports that run diagonal (forgot to draw them in... did so with computer editing...) to support the main frame.

(1" tube is blue)

The shelves will be held up with 1/2" square tube... Now that I think, the bottom of the tank base will be made out of 1/2" square tube welded onto the bottom of the main rails. They will be spaced to allow dust and crap to fall through, rather than building up on the cart.

(1/2" tube is red)

The shelves will likely be diamond tread aluminum, as I have a pretty big sheet of that stuff, supported by cross braces on the 1/2" tube main rails. The upper one will likely be 1" for extra strength.

Hmm... I might need more steel. Will have to update the quantities.

The handle brackets will be 1" sq. tube, and the handle itself will be 1/2" sq. tube. I will cut and grind the handle to the right size, just barely an interference fit, and weld some scrap plate and tap said plate for some good bolts. What will be done is a small piece of tube with a rubber pad will be put in the middle of the handle to hold the tank nice and snug. I don't have any confidence in chains, especially if it's halfway or more to the bottom of the tank... (wtf? what good will that do?)

If I ever get a tank, it'll be big.

So changes should not be that often. Even if they were, I'll have the compressor set up and and air ratchet will make bolt removal and installation real quick...

I think it'll be plenty strong enough, but if any of you see something that should be amended, feel free to holler.

I plan it to last for years, and years. Also the casters will be slightly recessed. Lower center of gravity is good, right?

The gun holder and such will be added after I get the cart together and figure out where I want it. Once that's done, I plan to paint it. Probably blue or black, maybe duo tone, I dunno.

Sorry about the crappy line overlay... laptop touch pad and drawing ain't a hand-in-hand thing, if you know what I mean.