mcb

ArboristSite Operative

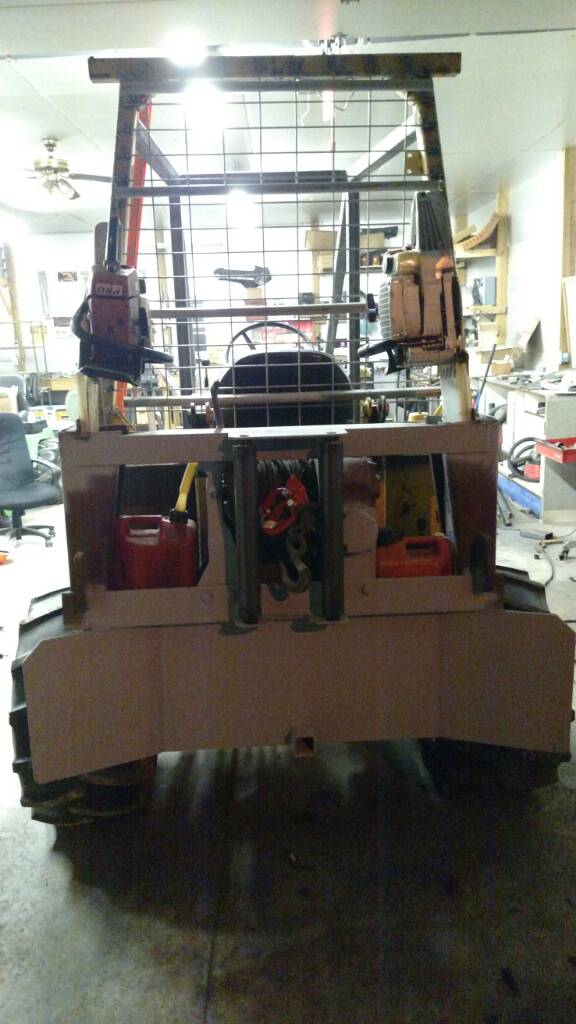

youre machine is capable of being a much, much more potent skidder than most people think. im confident i could get that unit dragging three buttlogs at a time, 20”x20' or so.

couple rules, fill the tires with used antifreeze after straining through a tee shirt and testing/adding concentrate for freeze protection. your nearest diesel/semi truck shop will surely give it to you by the drum because theyre paying for disposal. i suspect those tires will hold 25gallon each. fantastic how short and wide they are. the machine being short and low and square will have excellent maneuverability in tight woods.

gearing is probably 5.88, 6.17 or 7.17 and spools or detroits wouldnt be surprising. pull the dang covers already, we wanna know.

dont rush this build , plan out a big budget sketch and then do the parts you can afford as you can. keep your eyes peeled and other pieces will fall in your lap at the junkyard or wherever. i would mount a pair of parallell 12volt group 31 truck batteries toward the back and plop that 10k winch in the middle but leave room to build a future two hinge grapple that straddles it. grapples are vastly more productive but only if u can back up to the log. on the sides of those two posts i would mount one each of the harbor freight $60 quad winch up high as you can. strip off some cable to give it more snot and make the cutoffs into extensions you keep on the tractor. the center winch is for your big buttlogs.. real those in as 16s and bring em to the mill. specially white oaks $. use the side winches for retrieving extra pieces as you drive along, instead of having to unhook the buttlog, twitch the other one, lash em together, rehook etc. trencher ground speed is slow but torque, weight and traction are very high for pulling cable plows and running hydraulic motors. they have excess HP to compensate for the huge power loss of hydraulic motor inefficiency. anyhow, your machine is gonna pull more than you think.

next critical issue is front end ballast. what does your blade look like and how stout is it? number 1 priority for the front of that machine isna dozer blade with a log grapple, as heavy as you can make it. this is the difference between you pulling or wheelstanding hills. make the grapple so it can grab a 30” round, cuz those are the ones you will throw a disc out trying to get on your trailer. the blade shouldnt be very wide, less than the trackwidth of your machine so its not a hindrance getting through the woods. make the arms long and the ride high enough to push your logs up those sideboards onto your flatbed. limit the grapples open position mechanically so you can have it full open and be pushing full bore against it without bending the cylinder rods.. and positively use dual cylinders. i cut my trails, root rake, pop small stumps and push stuff over with my grapple rake constantly.. when im done youve got a beautiful singletrack recreation trail and richies will pay for nature walks. also, float is a must on the blade. backdrag float is how i do all my contouring. downpressure is how i anchor my machine forn heavy pull or lift the front wheels. in your case it would be worth the time to get the stroke right for enough tire clearance to sling chains on and off.

back at the landing, you can deck the logs onto your flatbed and also build a pen for logs on the neck of the trailer. drag trees long, buck and sort at landing, grapple them and drive onto trailer. lay a pair of straps down first and pile your matchsticks ontop in the pen sideways like railroad ties till youve got just enough room to put the machine on back. when you get home grapple or strap the whole bundle and drag it off. also make it possible to keep forewood and sawlogs seperate.

be warned, the machine will max out a car trailer pretty soon and you might want to trade up to a pintle hook equipment trailer with fixed ramps and plate fenders or deckover. id avoid triaxle. sharp turns suck with heavy loads.

another thing ill pitch out for the future, is a hydraulic up/down/float cat1 3 point hitch system. on that i would hang a european style logging buttplate sorta like farmi and wallenstein winches use.. the choker plate and lift are great for dragging in a ton of smaller wood at once.

i would build hitch the same as youd find on a old belarus tractor. one cylinder is fine if its central and extends to raise. same for a grapple.. no need for 2 cylinders on a small machine, its just added expense. round tube is superior to square tube in torsional loading and diameter offers more strength than wall thickness.

general thoughts on ballast are to make your added weight be functional weight.. not just suitcases clanging around. theyre the most expensive weight you can find. always start in the tires. then a front blade, add a grapple or root rake to that..or loader. a front toolbox or utility crate for chain, gas and saw.. a heavy rops with big tube sweeps.. u can fill them with cement if needed. concrete is always the cheapest weight.. $4 for sixty pounds. but why use concrete if u can grab another piece of wood that needs hauling anyway in a grapple blade?

anyhow.. keep pluckin away. im just as broke as you are.. junkyard is the source of all the gems you need. i got a part time job at one to keep the materials flowing. sell firewood, buy scrap. those markets are heavily in your favor right now.

couple rules, fill the tires with used antifreeze after straining through a tee shirt and testing/adding concentrate for freeze protection. your nearest diesel/semi truck shop will surely give it to you by the drum because theyre paying for disposal. i suspect those tires will hold 25gallon each. fantastic how short and wide they are. the machine being short and low and square will have excellent maneuverability in tight woods.

gearing is probably 5.88, 6.17 or 7.17 and spools or detroits wouldnt be surprising. pull the dang covers already, we wanna know.

dont rush this build , plan out a big budget sketch and then do the parts you can afford as you can. keep your eyes peeled and other pieces will fall in your lap at the junkyard or wherever. i would mount a pair of parallell 12volt group 31 truck batteries toward the back and plop that 10k winch in the middle but leave room to build a future two hinge grapple that straddles it. grapples are vastly more productive but only if u can back up to the log. on the sides of those two posts i would mount one each of the harbor freight $60 quad winch up high as you can. strip off some cable to give it more snot and make the cutoffs into extensions you keep on the tractor. the center winch is for your big buttlogs.. real those in as 16s and bring em to the mill. specially white oaks $. use the side winches for retrieving extra pieces as you drive along, instead of having to unhook the buttlog, twitch the other one, lash em together, rehook etc. trencher ground speed is slow but torque, weight and traction are very high for pulling cable plows and running hydraulic motors. they have excess HP to compensate for the huge power loss of hydraulic motor inefficiency. anyhow, your machine is gonna pull more than you think.

next critical issue is front end ballast. what does your blade look like and how stout is it? number 1 priority for the front of that machine isna dozer blade with a log grapple, as heavy as you can make it. this is the difference between you pulling or wheelstanding hills. make the grapple so it can grab a 30” round, cuz those are the ones you will throw a disc out trying to get on your trailer. the blade shouldnt be very wide, less than the trackwidth of your machine so its not a hindrance getting through the woods. make the arms long and the ride high enough to push your logs up those sideboards onto your flatbed. limit the grapples open position mechanically so you can have it full open and be pushing full bore against it without bending the cylinder rods.. and positively use dual cylinders. i cut my trails, root rake, pop small stumps and push stuff over with my grapple rake constantly.. when im done youve got a beautiful singletrack recreation trail and richies will pay for nature walks. also, float is a must on the blade. backdrag float is how i do all my contouring. downpressure is how i anchor my machine forn heavy pull or lift the front wheels. in your case it would be worth the time to get the stroke right for enough tire clearance to sling chains on and off.

back at the landing, you can deck the logs onto your flatbed and also build a pen for logs on the neck of the trailer. drag trees long, buck and sort at landing, grapple them and drive onto trailer. lay a pair of straps down first and pile your matchsticks ontop in the pen sideways like railroad ties till youve got just enough room to put the machine on back. when you get home grapple or strap the whole bundle and drag it off. also make it possible to keep forewood and sawlogs seperate.

be warned, the machine will max out a car trailer pretty soon and you might want to trade up to a pintle hook equipment trailer with fixed ramps and plate fenders or deckover. id avoid triaxle. sharp turns suck with heavy loads.

another thing ill pitch out for the future, is a hydraulic up/down/float cat1 3 point hitch system. on that i would hang a european style logging buttplate sorta like farmi and wallenstein winches use.. the choker plate and lift are great for dragging in a ton of smaller wood at once.

i would build hitch the same as youd find on a old belarus tractor. one cylinder is fine if its central and extends to raise. same for a grapple.. no need for 2 cylinders on a small machine, its just added expense. round tube is superior to square tube in torsional loading and diameter offers more strength than wall thickness.

general thoughts on ballast are to make your added weight be functional weight.. not just suitcases clanging around. theyre the most expensive weight you can find. always start in the tires. then a front blade, add a grapple or root rake to that..or loader. a front toolbox or utility crate for chain, gas and saw.. a heavy rops with big tube sweeps.. u can fill them with cement if needed. concrete is always the cheapest weight.. $4 for sixty pounds. but why use concrete if u can grab another piece of wood that needs hauling anyway in a grapple blade?

anyhow.. keep pluckin away. im just as broke as you are.. junkyard is the source of all the gems you need. i got a part time job at one to keep the materials flowing. sell firewood, buy scrap. those markets are heavily in your favor right now.