mikefunaro

Addicted to ArboristSite

I'm taking a US forest service approved chainsaw certification class at my college so that I can run saws with our Appalachian trail maintenance crew/woodsman team/whatever.

The instructor advocated sharpening each cutter as far back as required to remove any defects, and then individually adjusting each depth gauge to the desired .25 or .30.

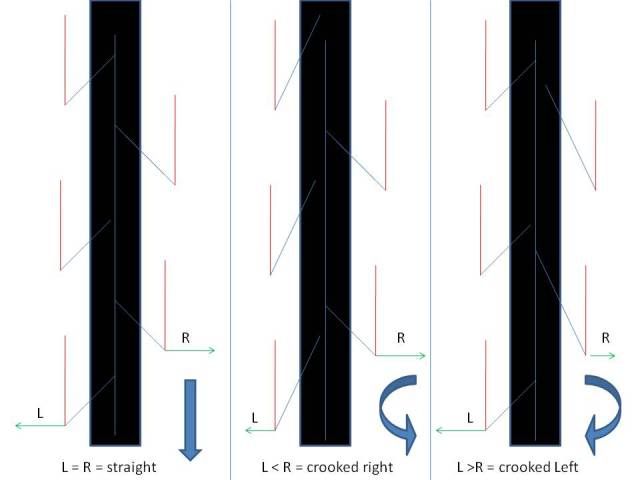

This went against anything and everything I've ever heard, so I suggested that this would cut with more vibration and potentially off to one side or another. He said that as long as everything had consistent depth gauges, the chain would still cut straight.

I think the main reason they advocate this is because these saws get rocked a lot and I guess they're trying to save on chain.

Has ANYONE heard this before? Do people agree?

MGF

The instructor advocated sharpening each cutter as far back as required to remove any defects, and then individually adjusting each depth gauge to the desired .25 or .30.

This went against anything and everything I've ever heard, so I suggested that this would cut with more vibration and potentially off to one side or another. He said that as long as everything had consistent depth gauges, the chain would still cut straight.

I think the main reason they advocate this is because these saws get rocked a lot and I guess they're trying to save on chain.

Has ANYONE heard this before? Do people agree?

MGF