deadeye308

ArboristSite Member

I just had a walnut tree taken down this week and wondering if I could get some advice on what would be the best thing to do with it. It was a pretty big tree.I took down part of the tree last summer before we built the garage. And just had a guy come take down the rest this week. I will try and post some pictures. I've asked around to a few people and I've heard everything from just burn it in your stove to it could be worth some money. I don't think sending it to a regular sawmill would be a good choice with all the limbs and different trunks, but I could be wrong. I think if some one had an Alaskan mill it would be the ticket. I just don't know of anyone in the area that does, which is another reason I am posting. I have been thinking and reading a good bit lately about chainsaw milling and it really has my intrest, but even if I do decide down the road to get into it, I still need some advice. I'll try and post some pictures and see if anyone can help or if there is any questions once someone has looked at it.

To the tape it is 6 foot high, back side is just over 5 foot with the slope of the ground.

Across the way the tap is running is 56 inches. the left side is what was just cut and right is what I cut down last summer, it does have some rot.

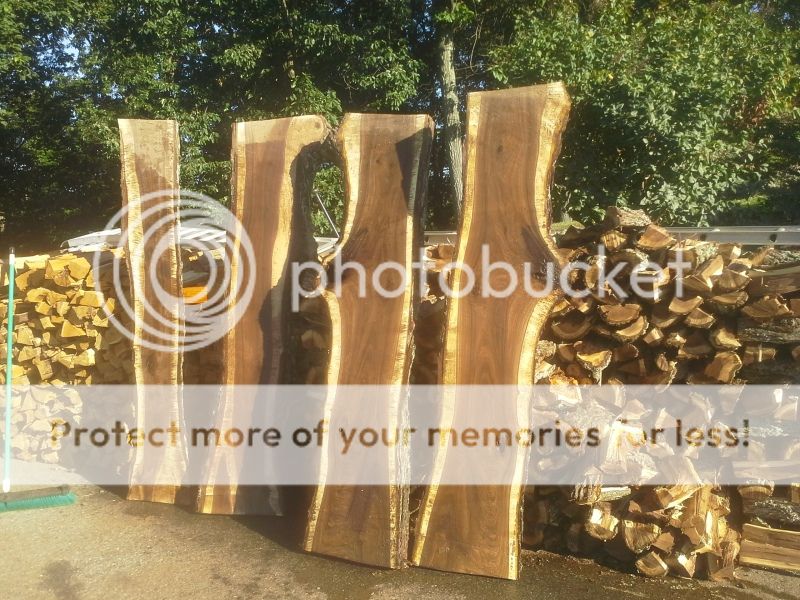

This piece is pretty straight, just has limbs coming out both side. after you get past the two big limbs its about 16 foot of nice straight wood. the whole piece is about 26 foot long

Just another look.

I hope the pictures turned out. If you have any advice or need any other pics or info or measurements I will add them later. I did not want to make to long of a first post. I'm just looking for advice because I would hate to see it go to waste if something could be done with it. Thanks in advance!

To the tape it is 6 foot high, back side is just over 5 foot with the slope of the ground.

Across the way the tap is running is 56 inches. the left side is what was just cut and right is what I cut down last summer, it does have some rot.

This piece is pretty straight, just has limbs coming out both side. after you get past the two big limbs its about 16 foot of nice straight wood. the whole piece is about 26 foot long

Just another look.

I hope the pictures turned out. If you have any advice or need any other pics or info or measurements I will add them later. I did not want to make to long of a first post. I'm just looking for advice because I would hate to see it go to waste if something could be done with it. Thanks in advance!