7sleeper

Addicted to ArboristSite

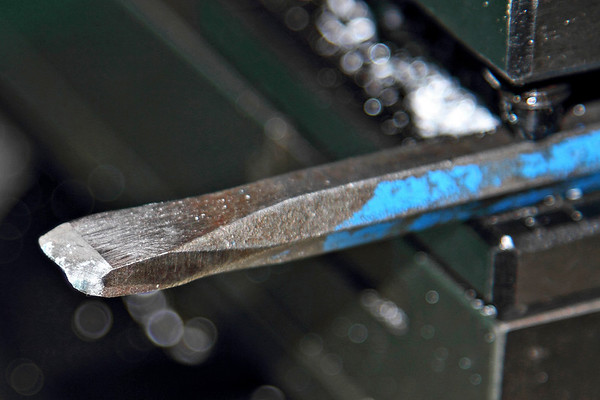

Here's a shot of my "razor sharp" tool. The ring end pins really did a number on it!

I think I went a little too far on the popup.

I was always wondering what these new strato saws are all about....:hmm3grin2orange:

7

!!

!!