Did Wiesco ever RUN these slugs in saw?

Or just make them and let come what be?

Or just make them and let come what be?

Did Wiesco ever RUN these slugs in saw?

Or just make them and let come what be?

Did Wiesco ever RUN these slugs in saw?

Or just make them and let come what be?

These have a sharp edge, so it should be quite accurate.

The accuracy of calipers when used like that is about the same as the clearance, making them unsuitable for determining the clearance in that application.

.

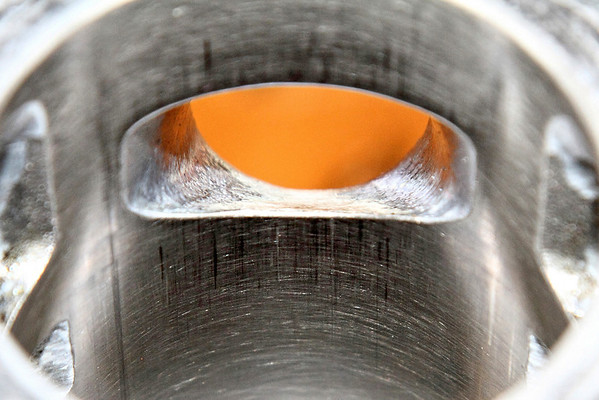

Here's the piston polished up. There are no signs of the scuffing. According to the calipers, I didn't really remove anything, just polished it up.

This is the intake side the had the worst wear.

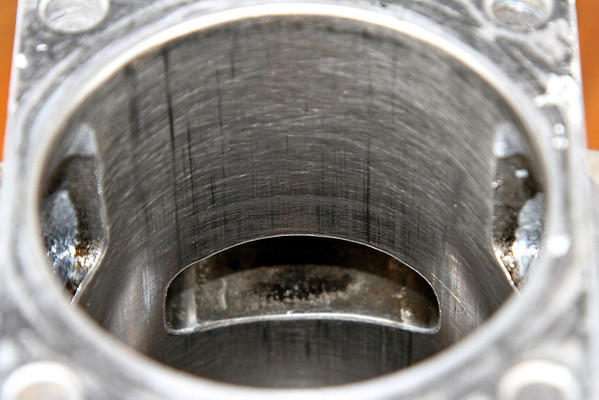

And the exhaust side.

How did you polish it?

where can you buy em?

Enco or MSC industrial supply will have them. The easiest way to set a dial bore gauge is with a ring gauge or gauge blocks with ends. A micrometer will do, it just takes longer. Companies like Sunnen make fancy bore gauge setting machines that are real easy to use, although very cashy.

Enco or MSC industrial supply will have them. The easiest way to set a dial bore gauge is with a ring gauge or gauge blocks with ends. A micrometer will do, it just takes longer. Companies like Sunnen make fancy bore gauge setting machines that are real easy to use, although very cashy.

Leeha, I agree with your train of thought. Bailey's is a great company with an excellent service record, but they seem to need a trained engineer on staff to communicate the spec's of engine components. It's a specialized task, if they are using anyone other than someone who has specialized training in this field then they are asking too much of the individual and placing the customer potenially at risk. I wouldn't ask a saw mechanic to do it, as good as one may be, there's alot more to it than meets the eye, the communication and language between engineers, whether it be software, civil, mechanical or whatever is usually different than what someone outside the field would be in my observations of product development processes.

Brass feeler gages can be used to measure skirt-to-bore clearance. They don't cost much and don't require a lot of skill to use.The accuracy of calipers when used like that is about the same as the clearance, making them unsuitable for determining the clearance in that application.

.