I decided to make this invention for a few reasons. First, there are times when I want to work on parts of a saw without removing the bar and chain. Second, the saw slides around lots of times when I want it to hold still. Third, I occasionally like to do sharpening with the chain on the bar and that means the second reason applies as well. So, my objective was to build a couple of jaws that grabbed the bar only, held the body of the saw in place and allowed the chain to move freely. In addition, I wanted the saw's body to be supported rather than suspended in mid-air as it would be if a typical mechanics vice was used instead.

The solution was to make a pair of 1 x 8 wooden jaws, loosely hinged at the bottom and with offset pads that allowed the chain to slide above and below them:

The "hinges" are simply two carriage bolts with lock nuts. The hole on the lock nut side is oversized to allow for the movement apart at the top. A pair of springs in blind holes holds the jaws open to make it easy to slide the bar in. I added a horizontal platform on one side to support the saw's body:

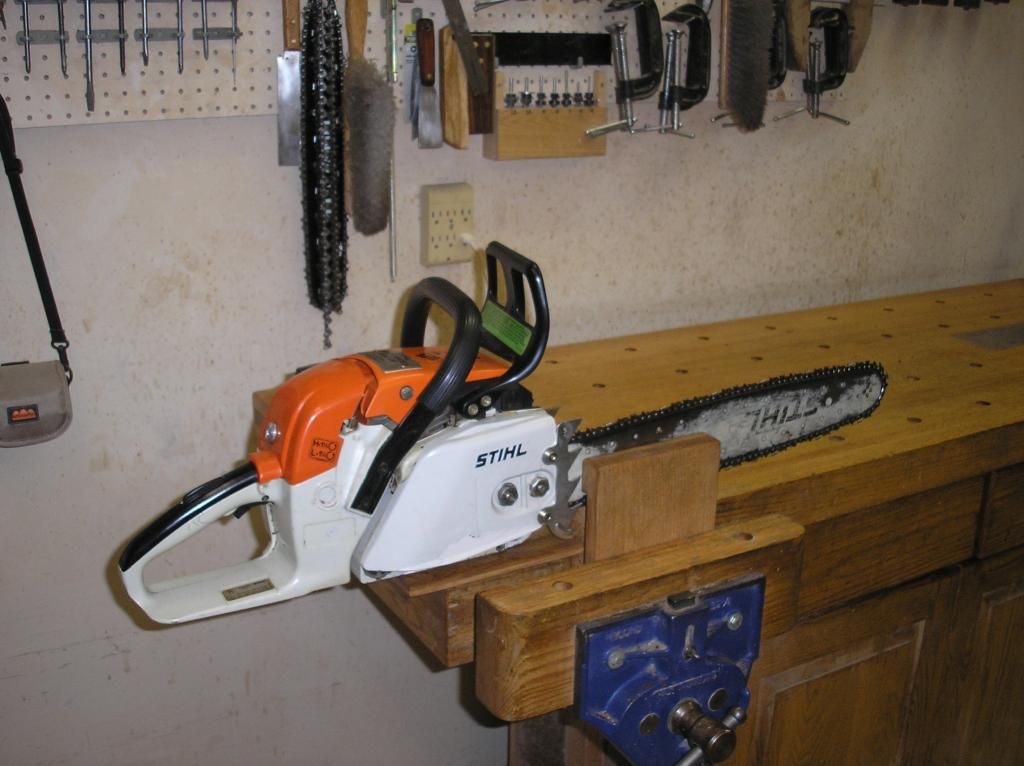

The platform for the saw body is only 1/2" thick, but it could have been thicker, and I kind of wish it was another inch or two longer. Regardless, here it is in action with my Stihl 028, securely clamped in place by my Woodworker's vise:

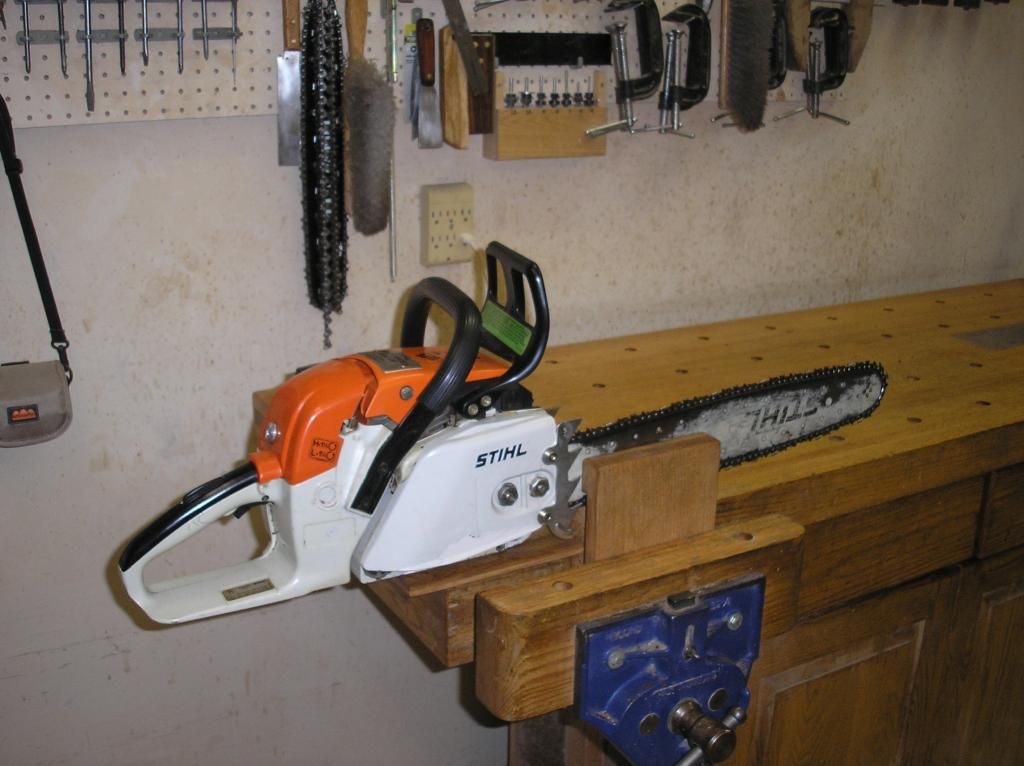

It's rather versatile, and here it is clamped with the saw pointed the other way:

So, you can work on either side of the saw, and it will not move around as you work. When you open the bench vise, the saw lifts out while the vise clamps and the platform remain intact. About the hardest part of making this was to taper the pads so they were dead flat when clamped and making contact with the bar. That insured maximum holding power.

I thought file sharpeners and Timberline users just might find this rather helpful, but remember that the intake, exhaust, ignition, and pull cord parts can be worked on with the bar and chain in place as well. And, you could also use it with a machinist vise. So, Forum, WDYT?

The solution was to make a pair of 1 x 8 wooden jaws, loosely hinged at the bottom and with offset pads that allowed the chain to slide above and below them:

The "hinges" are simply two carriage bolts with lock nuts. The hole on the lock nut side is oversized to allow for the movement apart at the top. A pair of springs in blind holes holds the jaws open to make it easy to slide the bar in. I added a horizontal platform on one side to support the saw's body:

The platform for the saw body is only 1/2" thick, but it could have been thicker, and I kind of wish it was another inch or two longer. Regardless, here it is in action with my Stihl 028, securely clamped in place by my Woodworker's vise:

It's rather versatile, and here it is clamped with the saw pointed the other way:

So, you can work on either side of the saw, and it will not move around as you work. When you open the bench vise, the saw lifts out while the vise clamps and the platform remain intact. About the hardest part of making this was to taper the pads so they were dead flat when clamped and making contact with the bar. That insured maximum holding power.

I thought file sharpeners and Timberline users just might find this rather helpful, but remember that the intake, exhaust, ignition, and pull cord parts can be worked on with the bar and chain in place as well. And, you could also use it with a machinist vise. So, Forum, WDYT?