steved

ArboristSite Guru

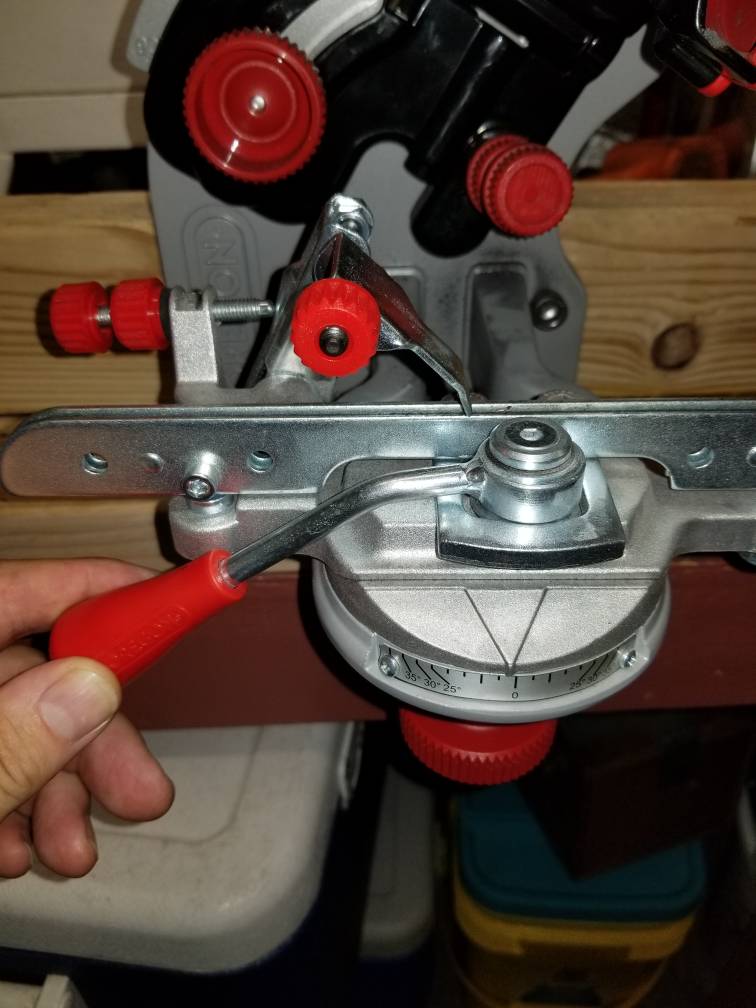

I was asked to give an impression of this sharpener because others might be interested. I'm working on Tapatalk, so I will be posting pictures in replies.

I was given a cheap bench top Timber Tuff as a gift. It works, it's very clunky, it vibrates, it is hard to setup, and it was falling apart when I got it (new in box). I used it a couple times, but felt I was doing more harm than good...the instructions were really lacking if i remember correctly. I'm going to state this right now, the Timber Tuff is probably a $40 tool and would probably serve a DIY homeowner who sharpens a chain every year well...but, you could also pocket the $ and pay to have it done.

Now the Oregon is probably a base semi-professional grinder. You can look these up, I got mine for $171 shipped from Amazon. It is quiet, it is smooth, everything is marked well...the instructions are ok, but meant for Oregon chain.

Now, it's probably been over five years since I used the Timber Tuff, and that long ago for my Father also...he commented how much nicer this Oregon is to the Timber Tuff, he didn't like the Timber Tuff at all.

Sent from my SM-G950U using Tapatalk

I was given a cheap bench top Timber Tuff as a gift. It works, it's very clunky, it vibrates, it is hard to setup, and it was falling apart when I got it (new in box). I used it a couple times, but felt I was doing more harm than good...the instructions were really lacking if i remember correctly. I'm going to state this right now, the Timber Tuff is probably a $40 tool and would probably serve a DIY homeowner who sharpens a chain every year well...but, you could also pocket the $ and pay to have it done.

Now the Oregon is probably a base semi-professional grinder. You can look these up, I got mine for $171 shipped from Amazon. It is quiet, it is smooth, everything is marked well...the instructions are ok, but meant for Oregon chain.

Now, it's probably been over five years since I used the Timber Tuff, and that long ago for my Father also...he commented how much nicer this Oregon is to the Timber Tuff, he didn't like the Timber Tuff at all.

Sent from my SM-G950U using Tapatalk