Tonight I began the process of porting the 361BB prototype that I have. The P&C look as good as new upon disassembly. The goal of this saw is to be competetive at a GTG level. It will also be used as a firewood saw. I took measurements on the saw tonight and will post them here. I would appreciate any feedback you guys might have on what numbers I should go with. Here's where it stands right now.

The exhaust seems aweful low, but this saw 4-stroked out to15,800. If I went to 98*, I would have to raise the roof .075"! To get to 95* would require raising it .115"! I can't imagine taking that much out. What numbers would you go with?

The exhaust port shape is pretty nice the way it is. The intake floor is very round. A lot of improvement to be made there. As you can see, I've got room to widen quite a bit, nearly .250" on both sides.

Whatcha think?

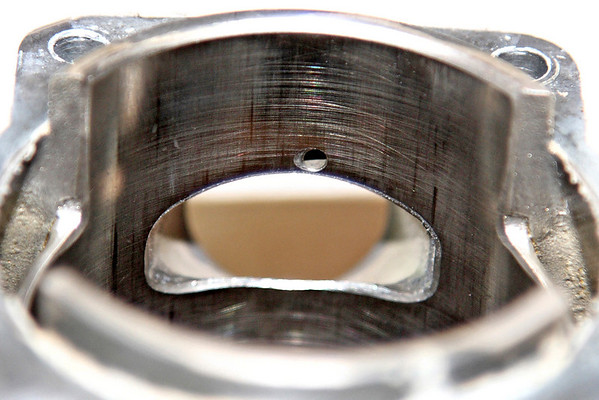

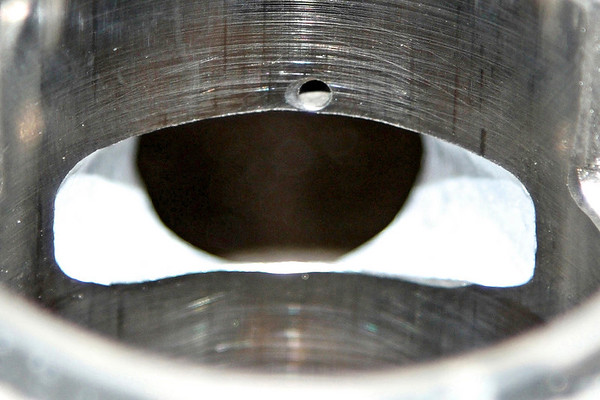

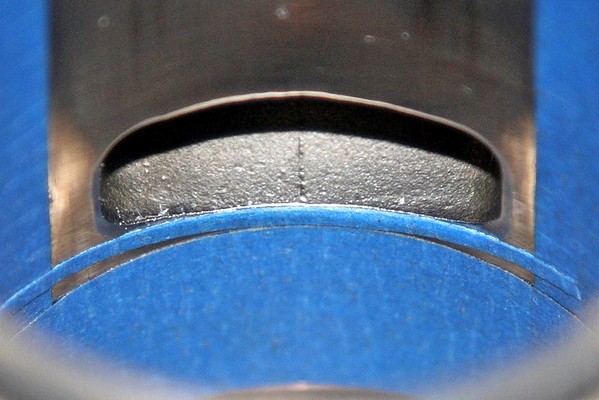

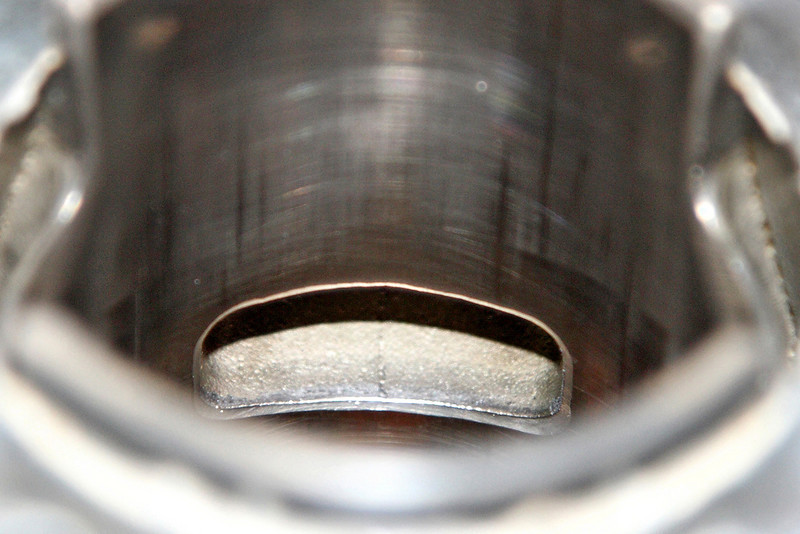

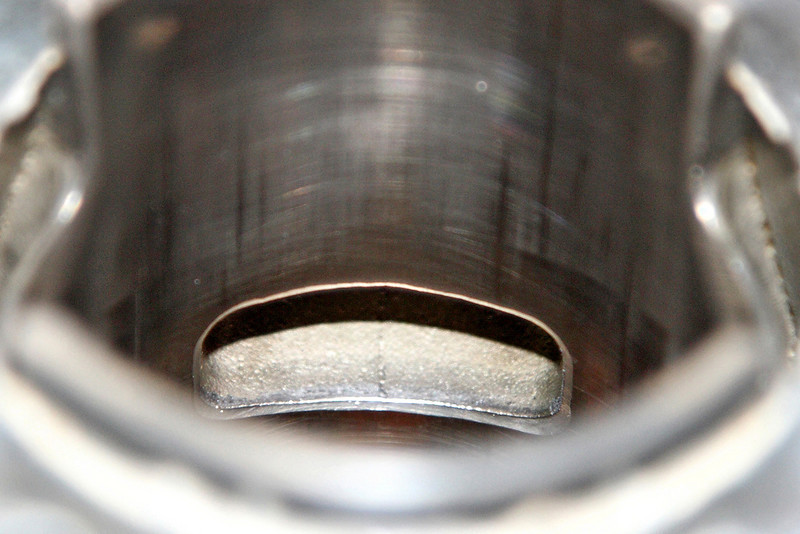

Exhaust Port

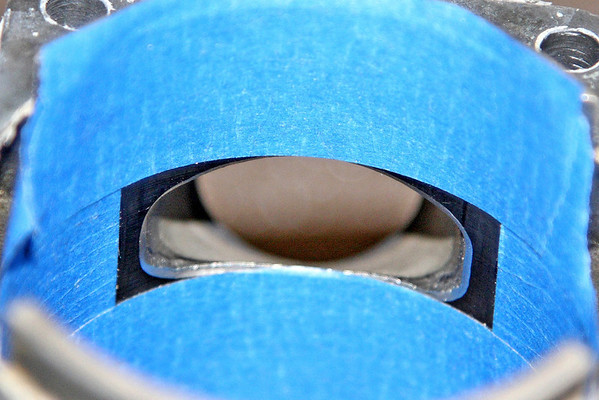

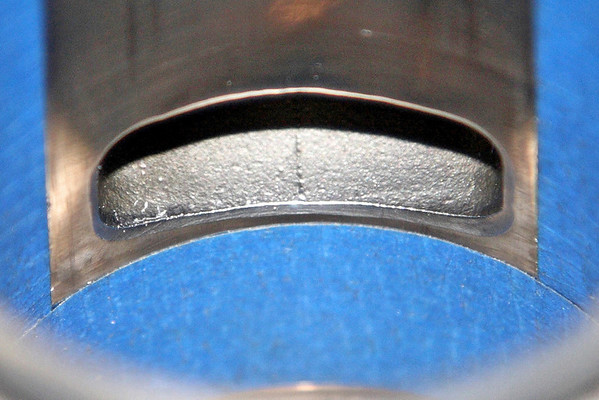

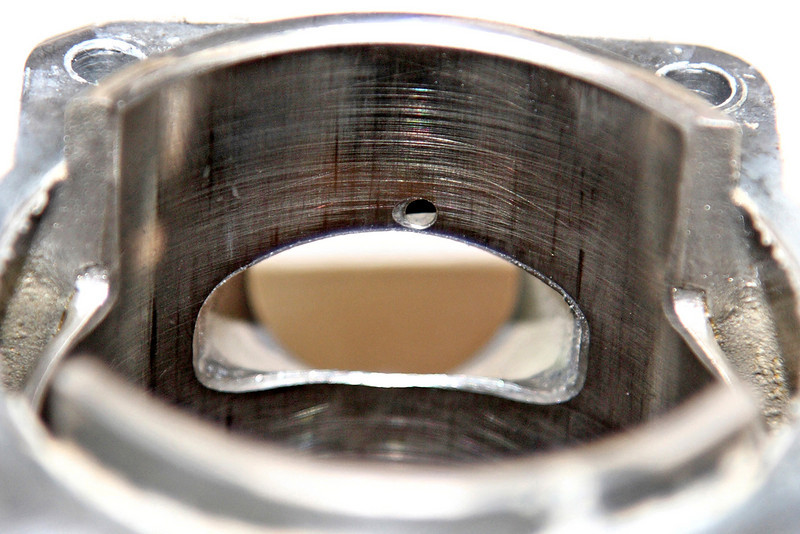

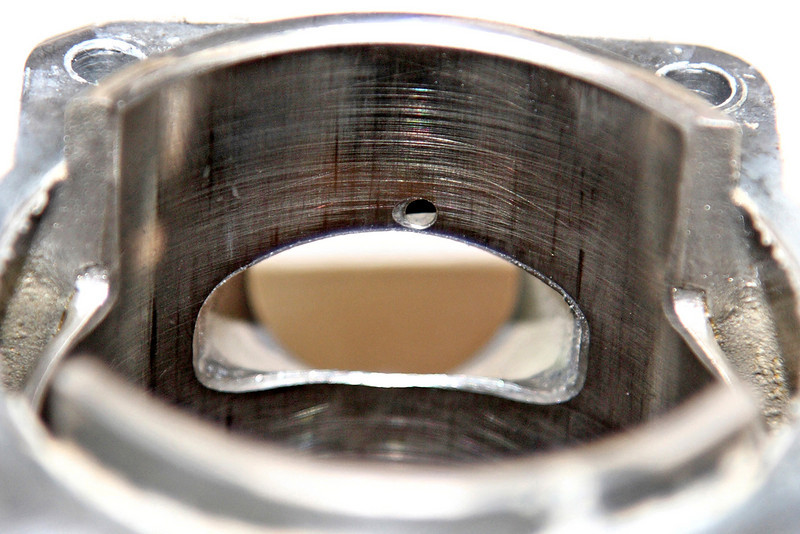

Intake Port

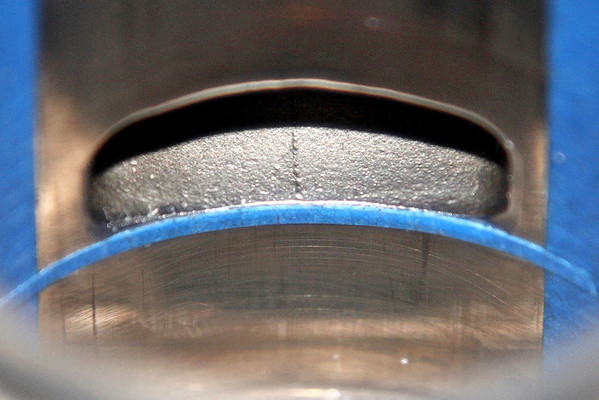

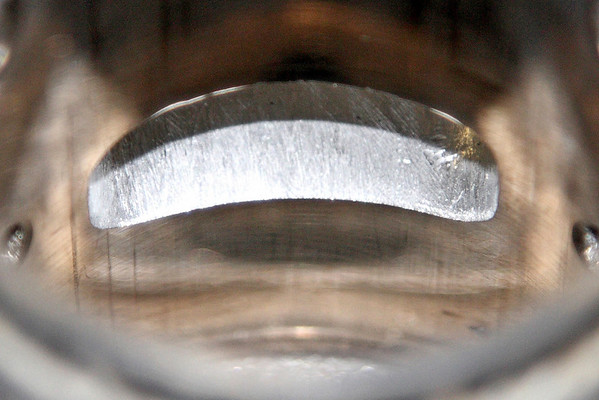

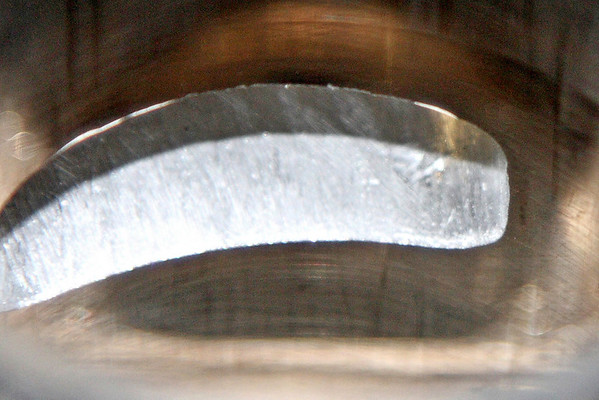

Crown after running 15,800.

- Squish = .017, no base gasket. That's how I've been running it.

- Compression was 185 cold after only a little run time. I forgot to check it tonight.

- Exhaust 105*

- Transfers 125*

- Intake 71*

- Blowdown 20*

- Exhaust width 1.00", can go to 1.25".

- Intake width 1.03", can go to 1.25".

The exhaust seems aweful low, but this saw 4-stroked out to15,800. If I went to 98*, I would have to raise the roof .075"! To get to 95* would require raising it .115"! I can't imagine taking that much out. What numbers would you go with?

The exhaust port shape is pretty nice the way it is. The intake floor is very round. A lot of improvement to be made there. As you can see, I've got room to widen quite a bit, nearly .250" on both sides.

Whatcha think?

Exhaust Port

Intake Port

Crown after running 15,800.