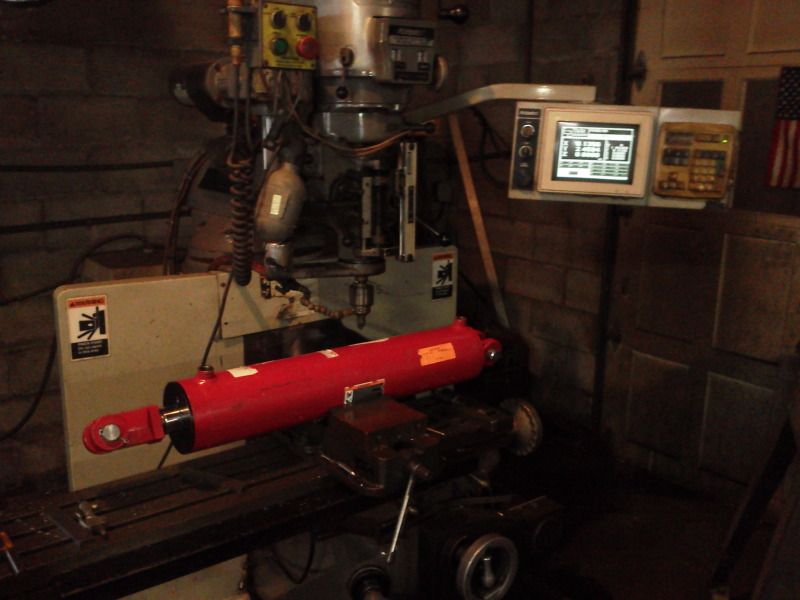

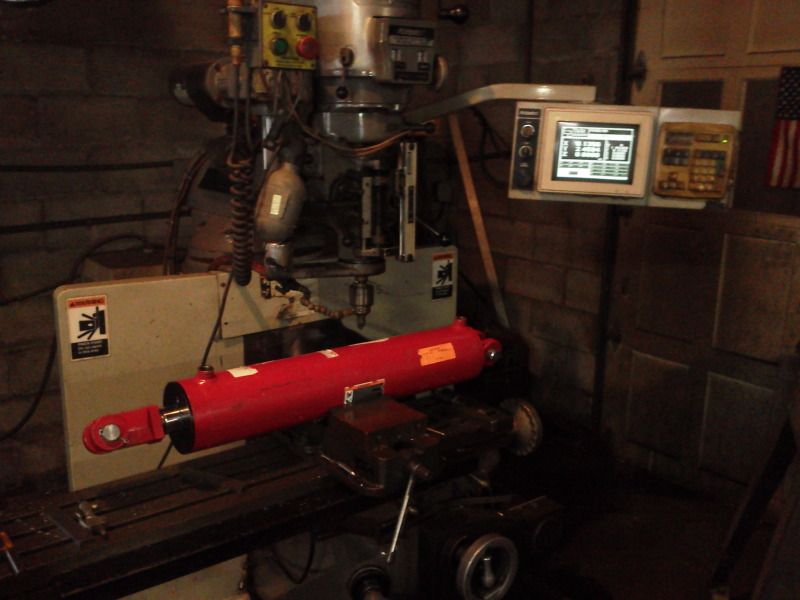

I pulled my old splitter out of the woods the other day.. it hasnt ran in over 20 years.. cylinder is missing, pump is froze.. tires are shot..LOL.. when i'm done I hope to have a winch on top pulling the logs to the saw..well so far I have gathered up some new pretty little shiny things to put on it.. a 14hp briggs and scrap iron motor, a brand new Stanley hydraulic chainsaw with 20 inch bar.. a new 5 x 24 cylinder, a new 22 gpm pump one lovejoy coupling and 2 new prince valves..

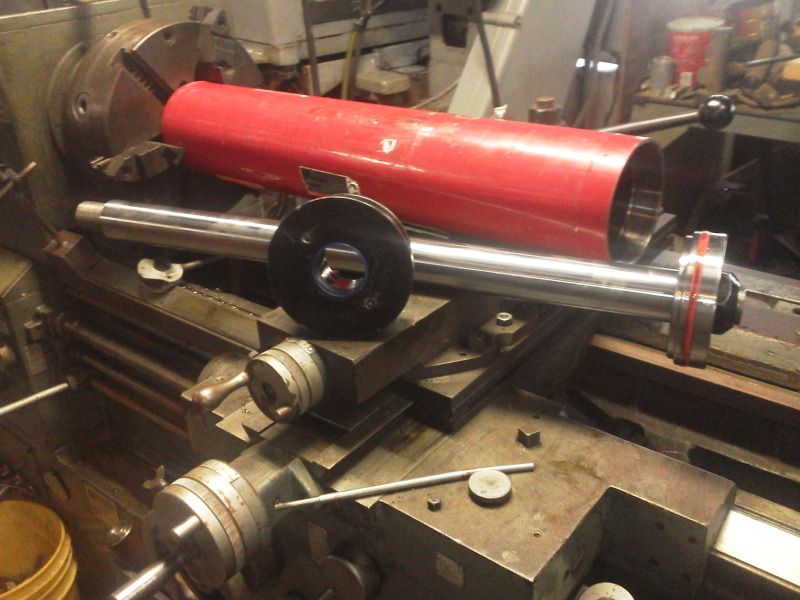

my cylinder has 1/2 pipe fittings on it..when I look down into the fitting it has a hole less than 3/8 ID for the fluid to go through.. the wall thickness of the fitting is thick enough for me to drill and tap out to 3/4 npt.. BUT.. the cylinder does not come apart.. its a Nortrac.. I called the company and they told me its welded and thats that.. so.. I want the bigger holes for the flow..but dont want all the shavings to go into my cylinder... any thoughts?? thanks!

my cylinder has 1/2 pipe fittings on it..when I look down into the fitting it has a hole less than 3/8 ID for the fluid to go through.. the wall thickness of the fitting is thick enough for me to drill and tap out to 3/4 npt.. BUT.. the cylinder does not come apart.. its a Nortrac.. I called the company and they told me its welded and thats that.. so.. I want the bigger holes for the flow..but dont want all the shavings to go into my cylinder... any thoughts?? thanks!