As most of you know, I've been in Orlando on business travel this week. So I'm just now getting around to posting about these new Wiseco pistons that came Monday.

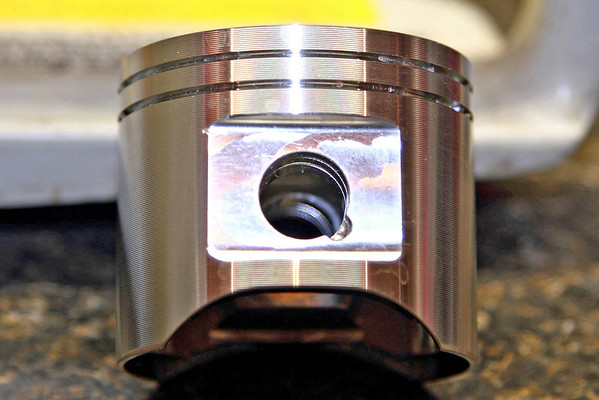

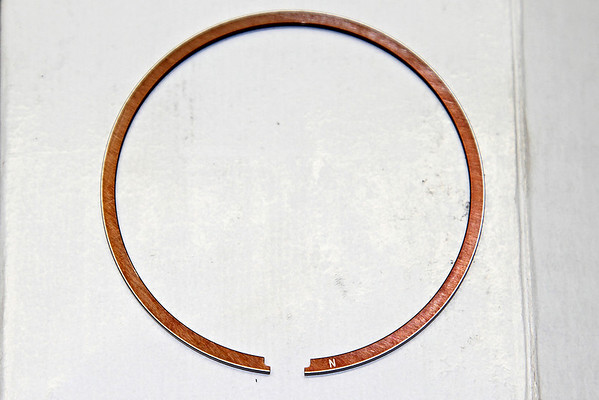

First of all, the quality of the forgings looks excellent. They all use thin 1mm rings. The 066 rings have end gaps of .009". Piston to cylinder clearance is about .0015"-.002", as best as I can measure.

My scale can only measure in .2 oz increments, so not very accurate at this weight. The factory Mahle piston came in at 3.0 and the Wiseco at 3.4, for nearly a 15% weight increase.

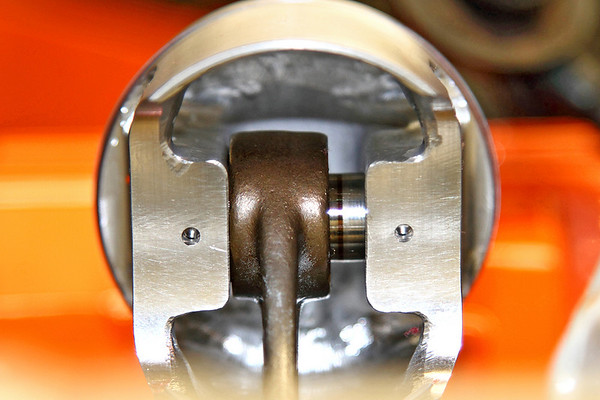

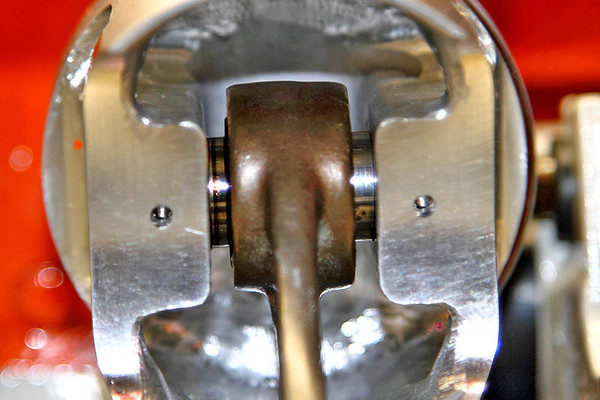

I've run into a couple rather serious issues. The 066 piston is much wider between the pin bosses, leaving .180" play of the piston from side to side, allowing the needle bearing to come out of the rod by the same amount. I do not yet know if this is an issue on any of the other pistons. It looks like I'll have to have a set of bushing/spacers machined up to take up that gap. That's going to add more weight to an already heavier piston.

The 044 piston looks to have a manufactures defect, where the ring end pins are way off center. This is allowing one ring to drop into the intake and the other into a transfer port. This piston is unuseable. The pins are properly centered on all of the other pistons.

This is the 044 piston. Notice how far off center the pins are to the right.

Well right of the window.

Well into the window.

The pencil marks are where the pins are.

LOTS of metal around the pin bosses. That's where all the extra weight is.

First of all, the quality of the forgings looks excellent. They all use thin 1mm rings. The 066 rings have end gaps of .009". Piston to cylinder clearance is about .0015"-.002", as best as I can measure.

My scale can only measure in .2 oz increments, so not very accurate at this weight. The factory Mahle piston came in at 3.0 and the Wiseco at 3.4, for nearly a 15% weight increase.

I've run into a couple rather serious issues. The 066 piston is much wider between the pin bosses, leaving .180" play of the piston from side to side, allowing the needle bearing to come out of the rod by the same amount. I do not yet know if this is an issue on any of the other pistons. It looks like I'll have to have a set of bushing/spacers machined up to take up that gap. That's going to add more weight to an already heavier piston.

The 044 piston looks to have a manufactures defect, where the ring end pins are way off center. This is allowing one ring to drop into the intake and the other into a transfer port. This piston is unuseable. The pins are properly centered on all of the other pistons.

This is the 044 piston. Notice how far off center the pins are to the right.

Well right of the window.

Well into the window.

The pencil marks are where the pins are.

LOTS of metal around the pin bosses. That's where all the extra weight is.

Last edited: