Mastermind

Work Saw Specialist

In this thread I will try to dispel some common myths and rumors about the late model MS660. I've Done more than a couple of these saws.....and have made a few mistakes. I learned a couple of tricks in the process and figured I would share them.

Here's the victim....a nearly new MS660....a tank or so has been put through it.

The HD2 filter is a performance enhancer all by itself. I've seen a 500rpm increase by just replacing the old filter with one of these.

Nice huh? I love working on new saws.

Here's another place we will find gains in cut speed. I cut .020 from the edge of the flywheel key and advance to ignition about 8°. The flywheel must be moved counterclockwise.

Here we open this tiny outlet up to 3/4". If more outlet is needed a dual port cover is a great idea.

In order to keep the bracing effect of this baffle, we cut off the end and about an additional 1/4" or so. I forgot to take a pic of that.

Inside the carb there is normally some casting flash at the venturi....this one was very smooth though. Most of the time we clean that up to enhance flow thru the carb.

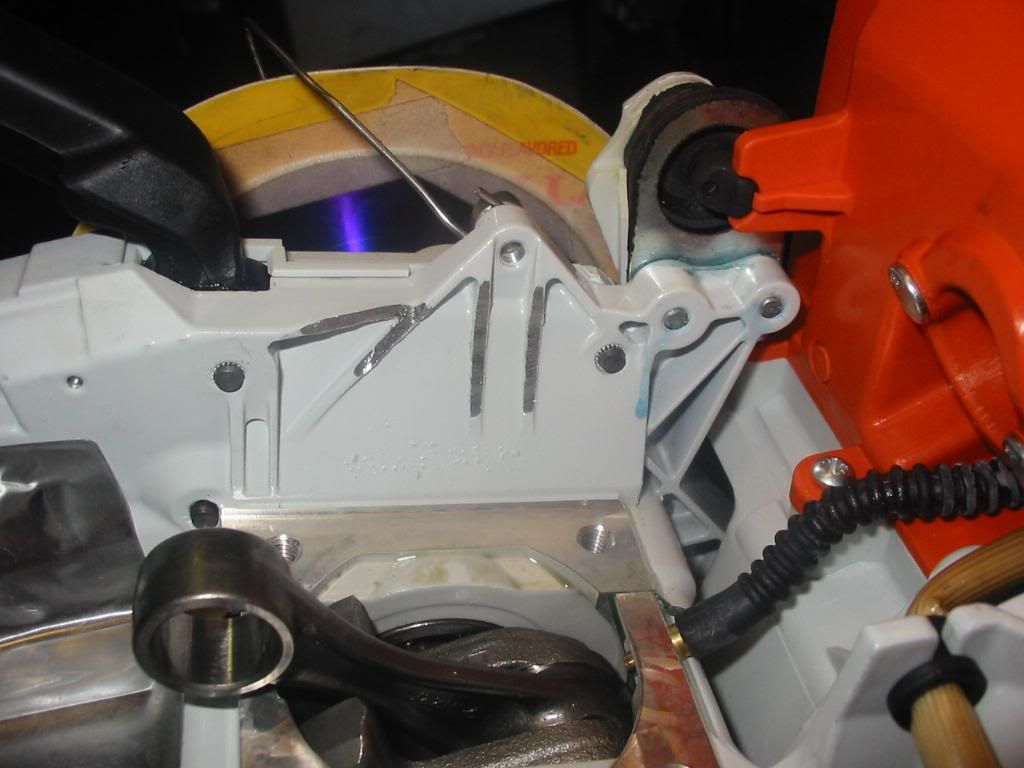

The machine work has been done in this shot. Without a base gasket this engine only had .007 squish clearance. We cut .063 from the squish band and removed .045 from the base to end up with a .025 squish clearance.

Here's the victim....a nearly new MS660....a tank or so has been put through it.

The HD2 filter is a performance enhancer all by itself. I've seen a 500rpm increase by just replacing the old filter with one of these.

Nice huh? I love working on new saws.

Here's another place we will find gains in cut speed. I cut .020 from the edge of the flywheel key and advance to ignition about 8°. The flywheel must be moved counterclockwise.

Here we open this tiny outlet up to 3/4". If more outlet is needed a dual port cover is a great idea.

In order to keep the bracing effect of this baffle, we cut off the end and about an additional 1/4" or so. I forgot to take a pic of that.

Inside the carb there is normally some casting flash at the venturi....this one was very smooth though. Most of the time we clean that up to enhance flow thru the carb.

The machine work has been done in this shot. Without a base gasket this engine only had .007 squish clearance. We cut .063 from the squish band and removed .045 from the base to end up with a .025 squish clearance.