K5

Vac test it. An air leak will give you high idle. Crank seals maybe?

Did you test that it holds vacuum too?

TIME!

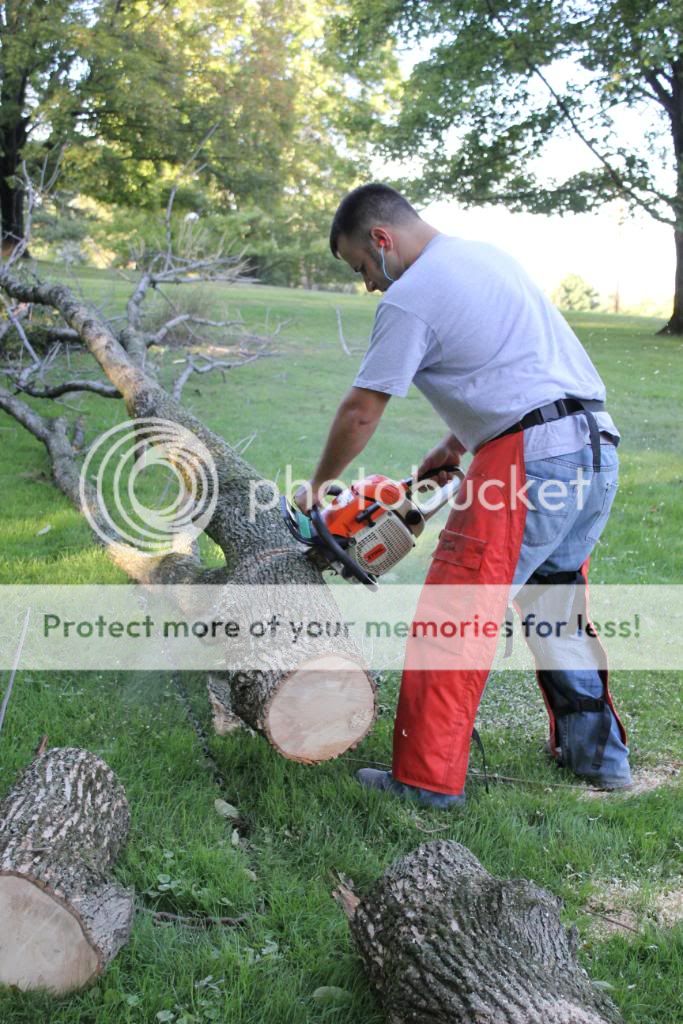

TIME! Good cuttin' little saw ya have there. But get some oil on that bar, dude! Looks to me like it was gettin' mighty warm.

Poge

Yeah, I agree. I have a couple myself that need a little love.

Enter your email address to join: