I had a thread going and I was going to sell my 044 vs rebuilding and keeping. After alot of feedback I was convinced to rebuild and try the saw for a whole to see how I like it. I got this saw from a buddy who told me it had a chain brake issue but had good piston. I paid 100$ for the saw and after I put a new brake handle on and found it worked fine, I saw the piston was shot. My buddy felt so bad he gave me a 036 pro saw with a bad piston to make up for it.

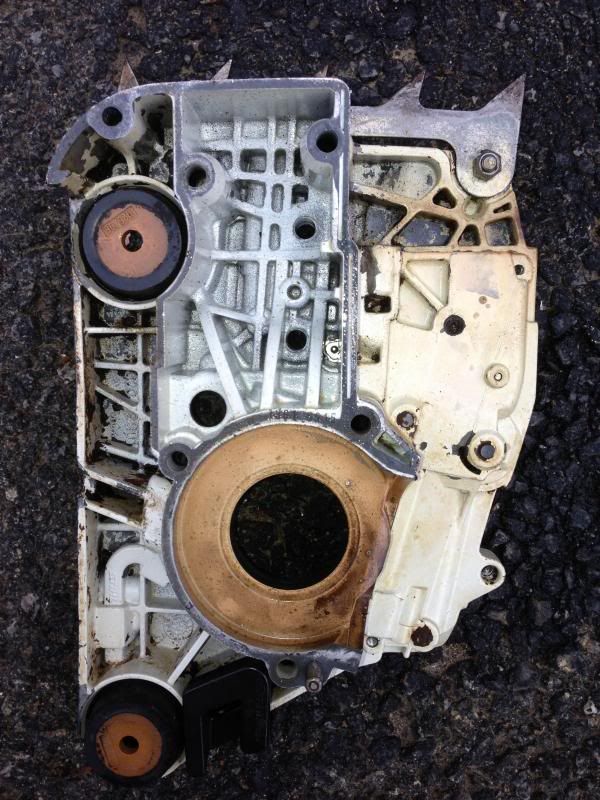

So that's the back round of the saw. I like threads with alot of pictures so here it goes. The brake handle was melted off, I'm not sure what caused this but the handle has been replaced and I want to make sure it doesn't happen again. Under the muffler there was a aluminum style tape, is this factory or is it something I can remove when cleaning.

I need to borrow my friends flywheel puller and than ill be taking the cyl off. Is anyone able to tell from the serial if this saw would be a 10 or a 12mm?

So that's the back round of the saw. I like threads with alot of pictures so here it goes. The brake handle was melted off, I'm not sure what caused this but the handle has been replaced and I want to make sure it doesn't happen again. Under the muffler there was a aluminum style tape, is this factory or is it something I can remove when cleaning.

I need to borrow my friends flywheel puller and than ill be taking the cyl off. Is anyone able to tell from the serial if this saw would be a 10 or a 12mm?