Ok: Checked all the bearings. Flushed out the crankcase with mixed fuel. New seals. Got another cylinder kit. Went over all edges to make sure they were properly chamfered. Set the squish to 0.027" using the soft solder method of measuring. Washed the cylinder and piston, lightly oiled with 2 stroke oil, installed the rings and assembled. Checked compression: 130 psi cold. Drained the fuel tank, installed the orange umbrella and removed the grub screw. Added another 100ml of oil to the fuel can. Mixed well, and refueled the saw.

Fired the saw up. Idles nice. Set the high speed for a strong 4-stroking when blipped. With the saw warmed up, took a slice out of a 2' diameter maple stump, moderate pressure, varying throttle from 1/2 to full -- still 4 stroking in the cut. Let the saw idle a bit, leaned out the high speed screw 1/8 turn. Still 4 stroking when blipped. Cut a second slice out of the stump. Checked the idle return in all positions and shut down the saw.

Started a hot compression check. 1st pull ~90 psi. Second pull, rising through 120. Suddenly pressure gauge dropped to about 5psi and the saw jammed. Removed the compression gauge and the piston was around TDC. Pushed back down quite easily, but jammed at TDC immediately on pulling the recoil again. WTF???

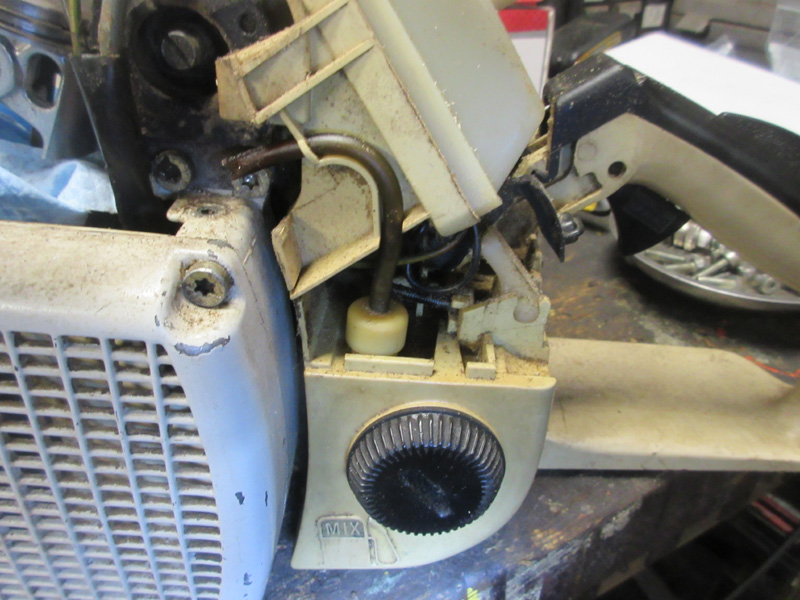

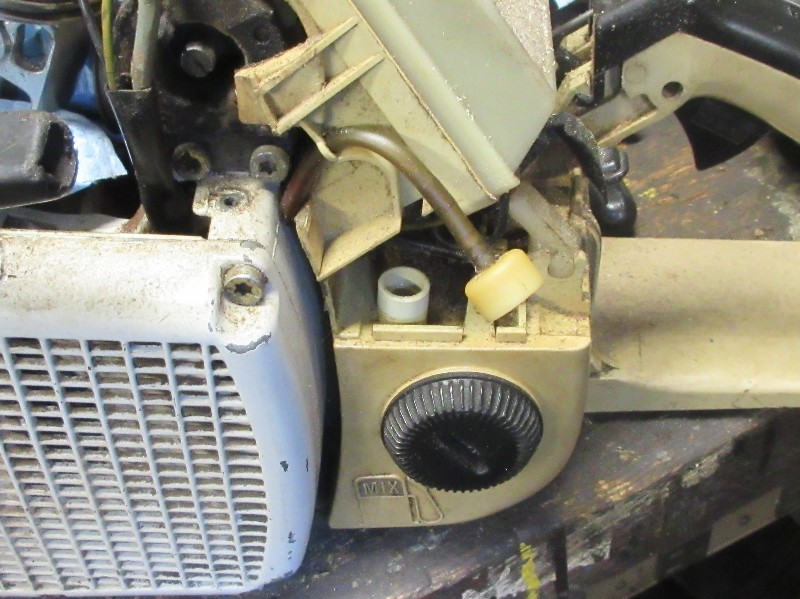

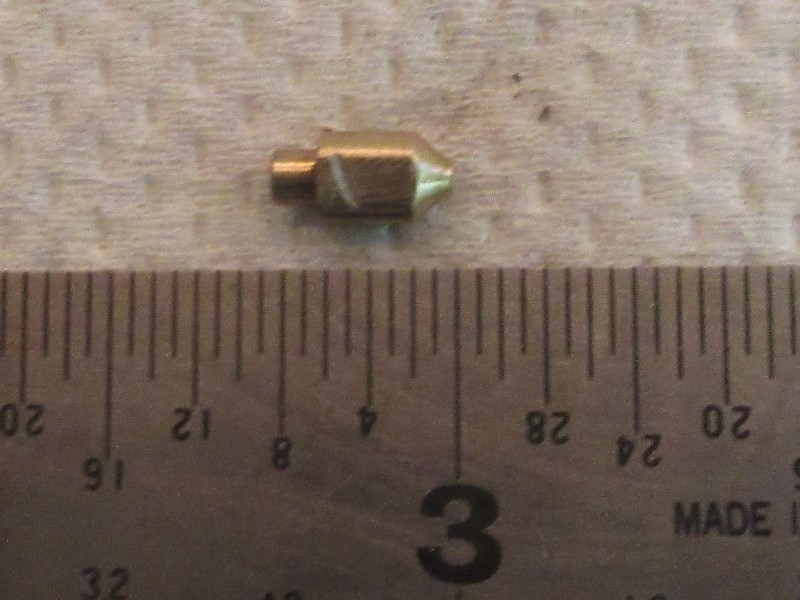

I removed the exhaust, looked inside, and found this little fellow sitting on top of my piston:

Brass coloured, non-magnetic, scores easily with a fine file, looks like brass. Where the heck did this come from and how the aitch-ee_double_hockey_sticks did it get inside my bloody engine???

I took this pic and stared at it scratching my head. Not a bearing, Doesn't look like a carb part, although it seems to be brass and vaguely looks like a float valve needle.

Wait a sec -- valve needle? Why would the pressure gauge drop before pushing the pressure release button? So I checked, and sure enough, the OTHER HALF OF THIS BUGGER IS STILL INSIDE MY CHEAP $#!+ HARBOR FREIGHT COMPRESSION TESTER HOSE!

Arrrggghhh.

So, what do all you guys use for a compression tester. 'Cause apparently I'm now in the market for a new one...