"sometimes noise is mistaken for power"

+2. Without timed cuts and controlled testing before and after opening up a muffler there is no way to know if it helped or not?

It's the same thing as making "seat of the pants" assessments of bolt on engine modifications to a vehicle. I've been at that game for over 40 years and in not one single instance have a found an improvement bolting on an intake, carburetor, loud mufflers, bug-zapping distributor or anything else and saw an improvement at the track back to back testing.

Case in point, although not chainsaw related, but how this deal really works. On several private drag strip rentals I've carried every intake that will fit under the hood of my car and tested them back to back, logged all the results and made comparisons. I did the same testing with spacers under the carb.

The intakes tested were Edebrock Performer, RPM, Torker 1, Torker II, Holley Street Dominator and Tomahawk. The spacers tested were 4 hole, fully open, fully divided and semi-open (between the secondaries only).

After making as many runs as I could get in and changing intakes when the smoke cleared and dust settled the factory cast iron intake was the quickest in ET, so it made the most power in the loaded RPM range. The Tomahawk ran the highest MPH but down considerably in 60' and short times, so it left "soft" and made a little more top end charge but LESS average power.

With spacers ALL of them ran SLOWER in ET than no spacer at all. The 4 hole and open spacers were complete "turds", but the semi-divided ran more MPH than the others so did make more top end power. Even so no spacer at all ran the quickest in ET so made the most average power in the loaded RPM range.

No comes the real kicker to a long and boring story. IF anyone were to drive my car with any of the single plane intakes on them and do a "seat of the pants" assessment of power improvements you would lay down you next 3 pay checks betting that they would run much quicker at the track than the stock iron intake. Those single plane intakes produce a very strong and noticeable "rush" of power in the upper mid-range and top end that we evaluate as a major improvement in power. In contrast the strong/smooth "locomotive" power curve produced by the factory intake is lackluster and boring. It just pulls hard everyplace, but no "rush" of power anyplace. So essentially the "butt-meter" is highly inaccurate for making assessments when it comes to power production.

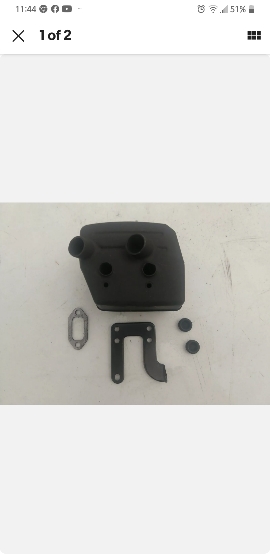

So, when we are cutting massive holes in chainsaw mufflers, or MIG welding on multiple exhaust pipes, porting the piss out of them, and just about everything else to improve power, more times than not you aren't helping them anyplace, and if you are the only way to know is to do some controlled and accurate testing to find out one way or the other. The exceptions to this will be recent production saws with CAT's or very restrictive mufflers designed to help them meet EPA requirements. For the older pre-emission stuff most have adequate exhaust flow and opening them typically just makes double hearing protection required more than anything else........FWIW......Cliff