I have an old Tecomec with reversing motor. I wouldn't have one without reversing capability.

Some of my tweaks:

1) I taped tygon fuel line lengths to the top casting to hold the allen wrenches for the shield and grinding wheel so they are always handy.

2) The head tilt is always either at true vertical or at 30 deg from vertical so I clamped stops at these angles so I don't have to strain my neck to read the scale on the back side every time.

3) By calibrating the depth adjustment (my grinding wheel moves 0.005" for each groove on the knob) and attaching a pointer on the lower friction-adjusting knob, I can uniformly grind all of the depth gauges to within a couple thousandths of the desired depth. I locate zero by running the adjusting knob upward to permit the wheel (stopped, of course) to rest on the top edge of the reference tooth (after sharpening ) and then run the adjuster down until the wheel just picks up and clears the tooth while applying the same downward pressure applied when finishing the actual grind.

4) I attached a flexible gooseneck lamp with a 100-watt brightness CF bulb for illumination. The built in lamp in the newer models is worthless since it is on only while the motor is on.

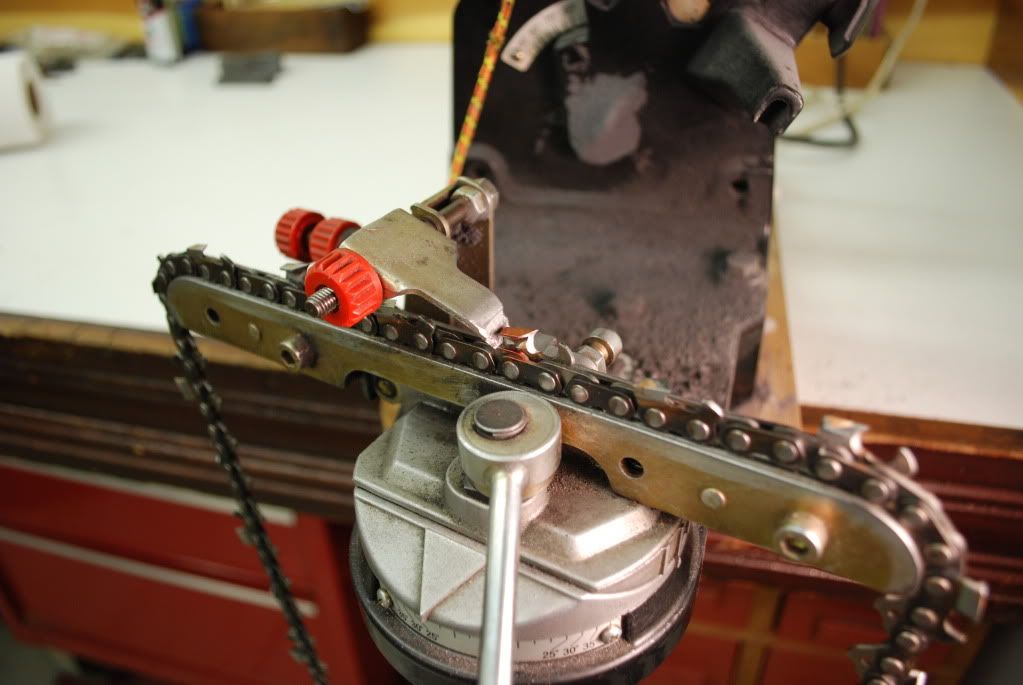

5) After wearing nearly through the vise rail with the cam clamp, I added a replacable wear plate held in place by the Allen head bolts holding the vise together.

6) To avoid having to readjust the tooth pawl when changing tooth sides, I use a short length of 1/4" fuel hose with a slit in the side to move the pawl back and forth. The slit hose is alternately pushing the pawl rearward or parked on the open side of the pawl bolt.

7) When grinding I use a tool to further stabilize the tooth against moving. The chain vise grips the drive links only, and with well-worn chains there can be wiggle room for the tooth. The tool is like an awl with a slight curl at the tip. I use it to bottom the drive links firmly while clamping, and I hold the tool tip firmly on the tooth while grinding.

8) I made a radial reference mark on the arbor where the wheels mount. I made radial reference marks on all the wheels, with matching marks on both sides of each wheel. When I mount a wheel, I align the marks pointing upward while pulling downward on the wheel while tightening the clamping bolt. This reduces the vibration caused by variations in wheel balance and slop in the arbor hole. If a wheel is smooth running when removed, it can be remounted and it will still run smooth.

8) I have experimented with forced air cooling, but I still don't have the right flexible nozzle rigged up.

9) The wheels I use are vitrified (mole-mab), Stihl diamond, and CBN. Each type has its fit.

10) The grinder is mounted on a length of lumber that can be clamped anywhere as needed.