Here's some pics of the port work. This is my first port job so go easy on Me with the comments.

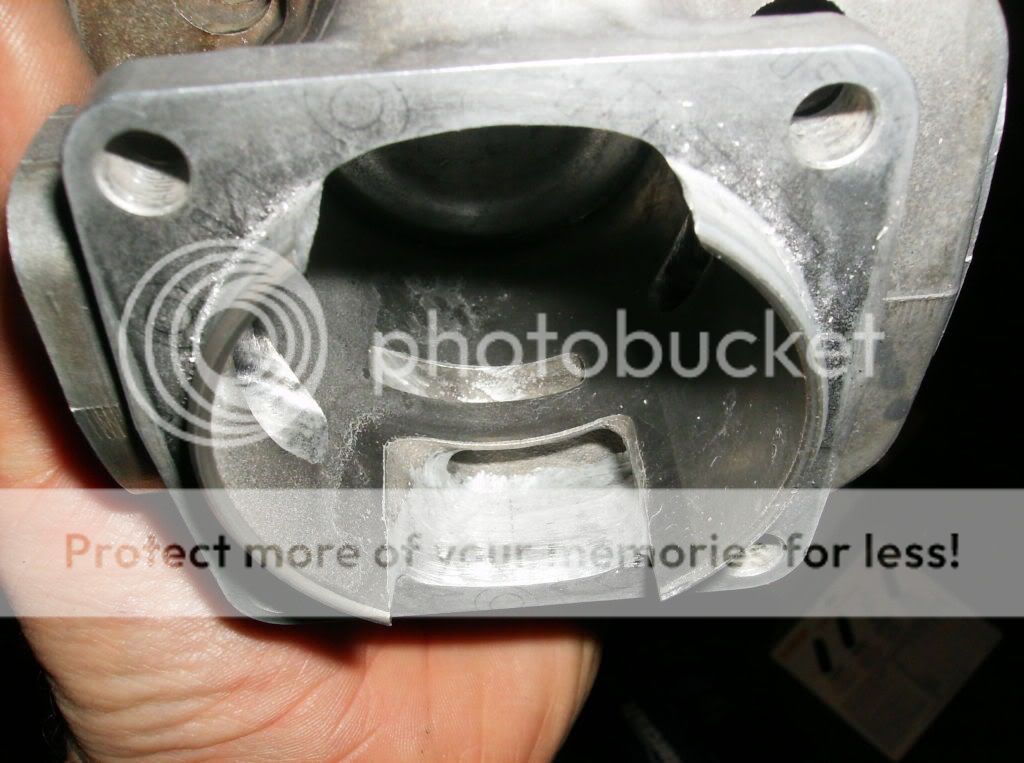

Intake:

Transfers before:

After:

Exhaust

I guess I didn't get any pics of the intake and exhaust before porting. They were both widened to within 2mm from the skirt edges. Exhaust was raised and intake lowered.

Timing after porting was:

Exhaust: 102° ATDC, 156° duration

Intake: 78° BTDC, 156° duration

I didn't raise the transfers so blowdown ended up at 24°

Sprayed the base gasket with some permatex gasket sealer and installed the cylinder for good. Ran a pressure/vac test on it.

Next, I drilled the 670 carb for the internal impulse so it will work with the 272 cylinder/intake manifold.

Sent 'er for a dip in the ultrasonic cleaner.

I put the carb together, then I cleaned up the tank and installed a new fuel line and filter and 2 new front a/v mounts. No pics of that, though.

All that's left now is to open up the muffler and some asssembly. More on that in a day or 2.