I'm gonna try to get something lined out with the BB kits...but this saw is going back to a OEM cylinder.

but before then i have a few things to work on. got a couple stiped holes that need repaired. 1 cylinder bolt hole, and 2 top cover bolt holes.

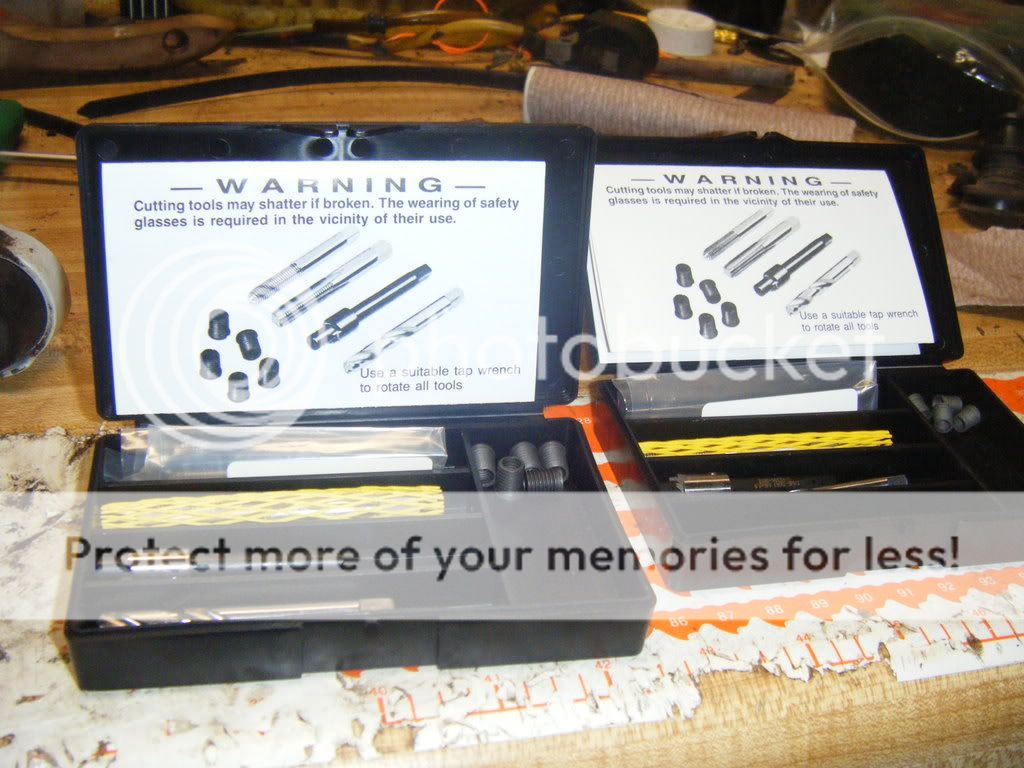

i purchased the 2 Time-sert its to repair these...and what can i say they seam to work great. easy to use and seem like a sturdy repair

the kits

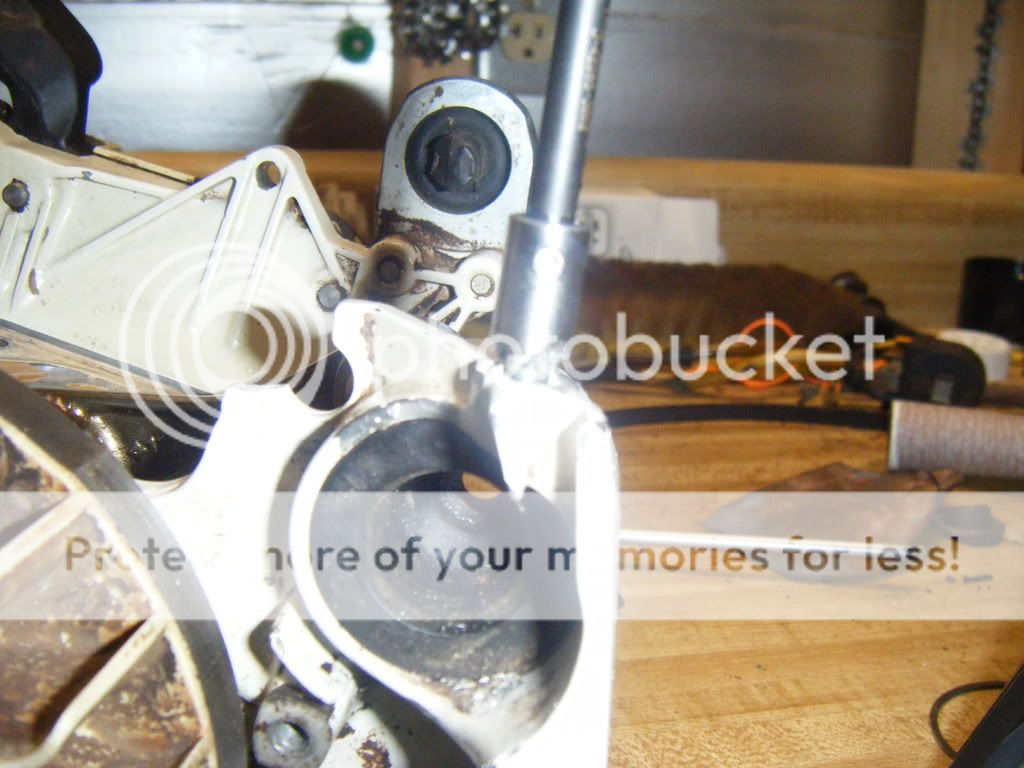

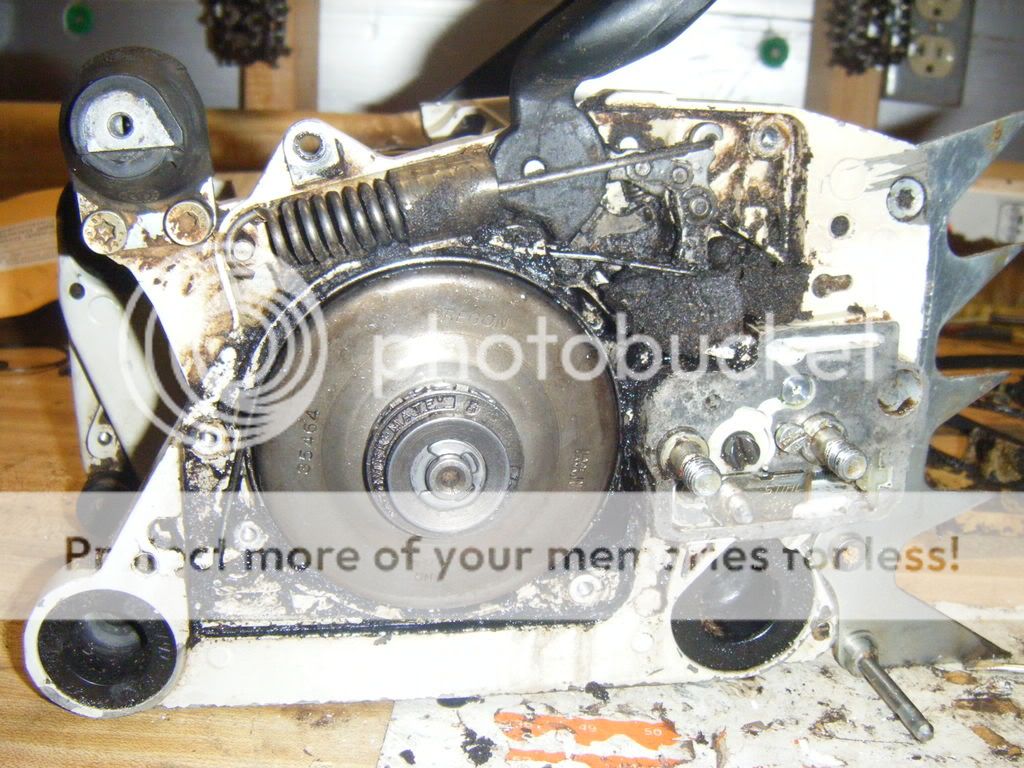

this is where i'm starting at

now for the hole repairs. most of this can be determined from the instructions but i thought this might help some of the people that were looking into these kits and want to know that steps involved. I had the shop vac sitting next to me and when i was cutting the metal i had it one to suck up any of the metal shavings

first drill out the original hole with the bit provided. make sure that the hole is square....drill out the hole-the metal doesn't take much force so you can most likely do it by hand (a T handle out of a tap & die set works good)

next counterbore the hole so that the insert can recess down into it

tap in the new threads using the tap provided

clean up the hole, squirt some oil on the new insert and get it started by hand...and then run it in with the insert driver. it will tighten up and then turn it just a tad more to flare out the end of it to hold it in place

i actually ended up rethreading all three of the top cover bolts..and it ended up being a couple minute job per thread after the first one

I had to remove the chainbrake in order to get clearance to fix the cylinder bolt thread..and this is what i found....DIRTY!!