tmessenger

ArboristSite Guru

Everyone's ideal saw comes in many flavors mine is 50cc, light as possible, 16" bar, well constructed, easy to start, minimum investment (read sweat equity) and reliable. Not asking too much no ? This saw is for a maximum of 14" hardwood, thinning / wood lot management which for me means a good deal of over head limbing and cutting the ever present shrub growth.

This of course meant trading and scrounging, anyone can pay retail right? It all started with a traded box of parts from Mastermind (024 cases, 026 crank and MS260 top end) some good bits ya hear and few things that need more help. I had a good clutch side cover from an 039 and the missing trigger lock so that went into the mix and got it running.

MasterM. and I discussed squish after I took some initial readings, the suicidal monkey recommended a beer can base gasket around .007 with sealer on both sides to give around .019 squish. This equated to right near 200psi on my gauge after assembly a bit hotter then I think I need so... Sthil offers two base gaskets one is .019 call a high compression gasket the other is .038 for normal compression. I made my own and it''s around .022 this yielded a still healthy 165 psi and more to my liking.

The next issue was the carb the one I got was one of those fixed jet monsters with a #56 main jet and it was too rich only pulling 12,000 rpm's even with a muffler mod. Up steps another trade deal from tbone75, the bone did not have the much coveted wt-194 but he did have a older model wt-22b from the 024~026 early days. Glad to report it works beautifully on this saw, good throttle response, idles nice and starts in half a pull warm (old school = new school).

Next up was the fixed rate oil pump, several problems here, first off the new clutch sprocket (one for the adjustable pump) was too deep and rubbing on this fixed pump, angle grinder to the rescue it was also over oiling my 16" bar. I managed to talk tbone out of his later model (plastic case) fixed pump in our trade deal and used my soldering iron to partially close off the inlet port on the pump. Still a bit more oil then needed but much better then the first all metal pump.

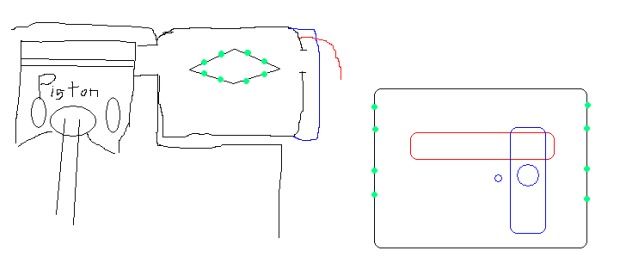

Last up was the muffler, my muffler is what I would call a bean counter muffler one that was designed by an accountant not an engineer. The early 026 models had a baffle in the back can, sort of a box around the exhaust inlet port with holes drilled in the side then an exit port in the front cover. These were not very restrictive and reasonably quiet. Next came the less costly to produce back can with just a sheet metal diverter in front of the inlet exhaust port, not as good but Oh well. And lastly the open can with a single 3/8" hole in the end cap, great they went from a good design to saving 30 cents in manufacturing cost to provide a muffler that is both restrictive and not all that quite. I ended up drilling an extra 3/8" hole in the end cap, this eliminated the restriction problem but was too noisy for my taste so I added an extra diverter plate in the back can to break up the sound wave (see photo). This works well no power loss to the modded open can design and it's a good deal quieter.

Oh yeah the bar and chain, my local saw shop had a bunch of these NOS Windsor Speed Tip bars lying around the hitch was they are short 16" 3/8 58g and Pioneer mount but for $10 I've had my eye on them for a time. Well after doing some close inspection they would work fine as Stilh mount, oil hole was good, adjuster hole was good but the slot need work (angle grinder + file and all is good ). The new chain was the good old Oragon 73 DL nothing wrong there.

All in all this was a fun and rewarding project, the 024/026/260 is a good runner I think it would run with the healthy 028 super I had last year and is 2.5 lbs lighter.

This of course meant trading and scrounging, anyone can pay retail right? It all started with a traded box of parts from Mastermind (024 cases, 026 crank and MS260 top end) some good bits ya hear and few things that need more help. I had a good clutch side cover from an 039 and the missing trigger lock so that went into the mix and got it running.

MasterM. and I discussed squish after I took some initial readings, the suicidal monkey recommended a beer can base gasket around .007 with sealer on both sides to give around .019 squish. This equated to right near 200psi on my gauge after assembly a bit hotter then I think I need so... Sthil offers two base gaskets one is .019 call a high compression gasket the other is .038 for normal compression. I made my own and it''s around .022 this yielded a still healthy 165 psi and more to my liking.

The next issue was the carb the one I got was one of those fixed jet monsters with a #56 main jet and it was too rich only pulling 12,000 rpm's even with a muffler mod. Up steps another trade deal from tbone75, the bone did not have the much coveted wt-194 but he did have a older model wt-22b from the 024~026 early days. Glad to report it works beautifully on this saw, good throttle response, idles nice and starts in half a pull warm (old school = new school).

Next up was the fixed rate oil pump, several problems here, first off the new clutch sprocket (one for the adjustable pump) was too deep and rubbing on this fixed pump, angle grinder to the rescue it was also over oiling my 16" bar. I managed to talk tbone out of his later model (plastic case) fixed pump in our trade deal and used my soldering iron to partially close off the inlet port on the pump. Still a bit more oil then needed but much better then the first all metal pump.

Last up was the muffler, my muffler is what I would call a bean counter muffler one that was designed by an accountant not an engineer. The early 026 models had a baffle in the back can, sort of a box around the exhaust inlet port with holes drilled in the side then an exit port in the front cover. These were not very restrictive and reasonably quiet. Next came the less costly to produce back can with just a sheet metal diverter in front of the inlet exhaust port, not as good but Oh well. And lastly the open can with a single 3/8" hole in the end cap, great they went from a good design to saving 30 cents in manufacturing cost to provide a muffler that is both restrictive and not all that quite. I ended up drilling an extra 3/8" hole in the end cap, this eliminated the restriction problem but was too noisy for my taste so I added an extra diverter plate in the back can to break up the sound wave (see photo). This works well no power loss to the modded open can design and it's a good deal quieter.

Oh yeah the bar and chain, my local saw shop had a bunch of these NOS Windsor Speed Tip bars lying around the hitch was they are short 16" 3/8 58g and Pioneer mount but for $10 I've had my eye on them for a time. Well after doing some close inspection they would work fine as Stilh mount, oil hole was good, adjuster hole was good but the slot need work (angle grinder + file and all is good ). The new chain was the good old Oragon 73 DL nothing wrong there.

All in all this was a fun and rewarding project, the 024/026/260 is a good runner I think it would run with the healthy 028 super I had last year and is 2.5 lbs lighter.

Last edited:

Good stuff

Good stuff