drf255

BAD CAD

Sorry for the dumb question.

I picked up an old 618 Craftsman/Atlas lathe. The CAD continues.....

Haven't fully cleaned and set it up, but got it for $350.

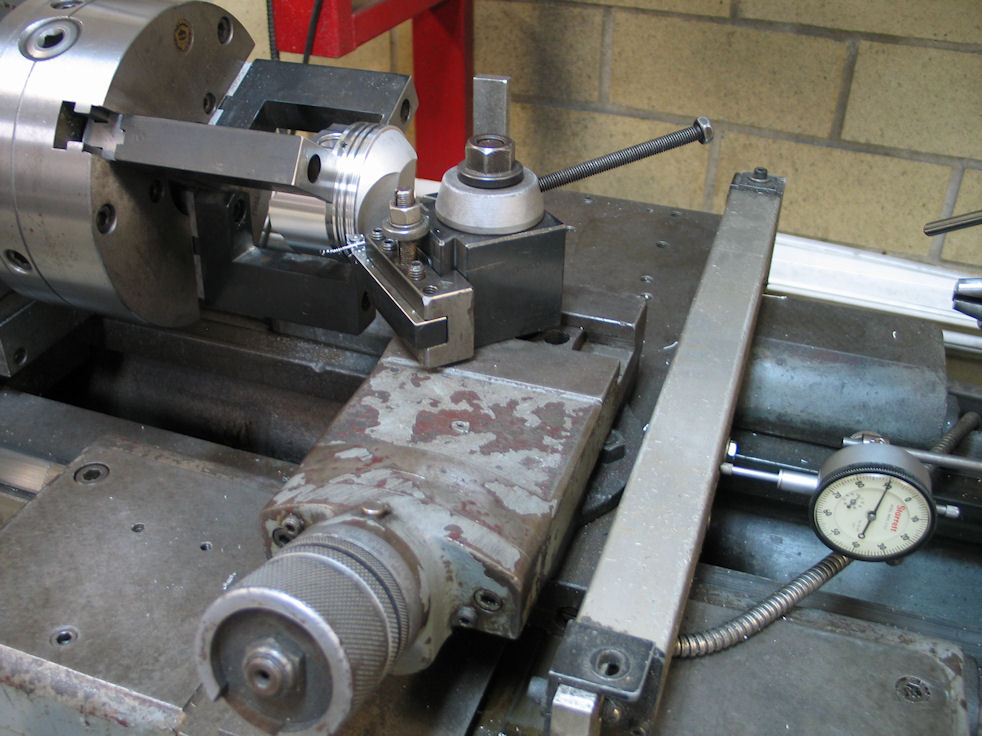

It's got a 4" 3 jaw chuck. Just for shizz and giggles, I tried to chuck up a ms250 piston I welded a dome on for machining. The skirt on both sides encompasses less that a quarter of the circumference. No matter how I rotate it, I can't find a point where all the jaws are contacting the round of the piston.

Any advice here? I'm sure I'm just missing something. I tried the search function, here and on google, and came up with nothing.

Thank you.

I picked up an old 618 Craftsman/Atlas lathe. The CAD continues.....

Haven't fully cleaned and set it up, but got it for $350.

It's got a 4" 3 jaw chuck. Just for shizz and giggles, I tried to chuck up a ms250 piston I welded a dome on for machining. The skirt on both sides encompasses less that a quarter of the circumference. No matter how I rotate it, I can't find a point where all the jaws are contacting the round of the piston.

Any advice here? I'm sure I'm just missing something. I tried the search function, here and on google, and came up with nothing.

Thank you.