It's not the corner radius that is critical. What is critical is the shape of the top and bottom of the port. It they're too flat, they'll catch a ring and trash the engine.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cylinder Porting for Dummies....

- Thread starter teacherman

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

volks-man

Arboristsite.com Spooner

blsnelling + timberwolf + others

thanks for all your help with my echo cs-440 port project.

work done:

widened exhaust

widened intake (one side only, ring end issue)

huge change in transfers at cyl-case intersection.

small notches added to bottom of piston at lower end transfer.

pop-up added to piston

jug lowered by .020, squish from .032 to .020

muffler opened more

retune by ear.

results:

immediatly i could hear the compression (before i opened the muffler) you guys know what i mean... the saw has a tinnier sound idling like my stihls.

i never timed a cut before teardown. seat of the pants testing says the saw turns a fraction faster than before (will tach later). the saw absolutely, definitly, positively has more torque, and lots of it. you can almost lean on it as hard as my 361. before the mods it was a torqueless wonder.

before the mods it was a torqueless wonder.

i think that i need to toss the 18" bar + .325, and grab a 16" + 3/8.

i honestly believe it will pull it now!

thanks for all your input guys!

thanks for all your help with my echo cs-440 port project.

work done:

widened exhaust

widened intake (one side only, ring end issue)

huge change in transfers at cyl-case intersection.

small notches added to bottom of piston at lower end transfer.

pop-up added to piston

jug lowered by .020, squish from .032 to .020

muffler opened more

retune by ear.

results:

immediatly i could hear the compression (before i opened the muffler) you guys know what i mean... the saw has a tinnier sound idling like my stihls.

i never timed a cut before teardown. seat of the pants testing says the saw turns a fraction faster than before (will tach later). the saw absolutely, definitly, positively has more torque, and lots of it. you can almost lean on it as hard as my 361.

i think that i need to toss the 18" bar + .325, and grab a 16" + 3/8.

i honestly believe it will pull it now!

thanks for all your input guys!

Once you run a ported saw, you're ruined forever. Congrats on a successful job.

volks-man

Arboristsite.com Spooner

Once you run a ported saw, you're ruined forever. Congrats on a successful job.

silly question, i know, but do all saws respond like this?

night and day difference in torque!

i really only knocked the chamfers off the exhaust and one side of intake (intake was already nearly as big as intake boot anyway). i can only figure that those transfers closed off almost completely as a way to control emmisions by way of limiting intake charge being sucked out by exhaust.....

basically the saw only got just enough fuel/air to run, but not run strong.

anyway, if all saws respond similarly, then i think i have another echo and a poulan/craftsman i can play with before i attempt work on the stihls.

thanks again!

Crofter

Addicted to ArboristSite

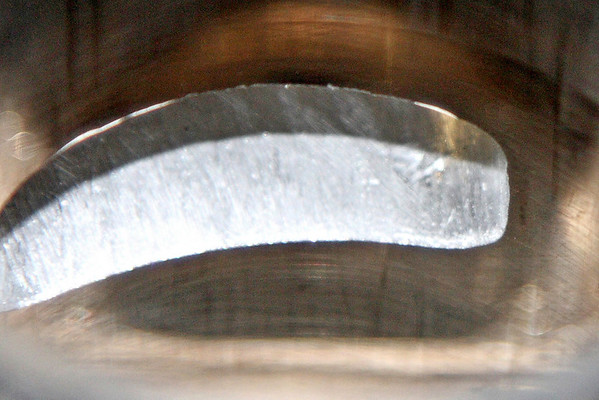

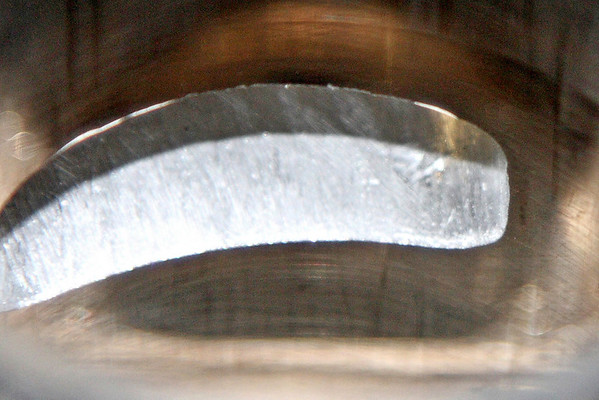

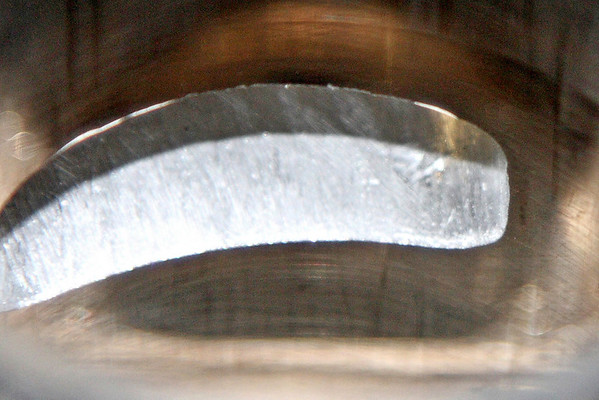

Ring expansion plus any gas pressure behind it in the ring groove is constantly trying to bulge the ring out into the unsupported opening of the port and the wider you make the ports as a percentage of bore diameter the worse the bulge.

If the top and bottom of the ports have an arch to them the ring is gradually squeezed back in from each side of the port. With no arch the ring suddenly is brought up against the whole width of the port and tends to get slapped instead of eased back into the ring groove. Sometimes if they catch the ring snaps; sometimes the ring lands of the piston get shmucked or maybe both.

That sharp corner in port in the picture not only reduces the gradual squeezing effect on the rings, but because of the unbalanced shape from one side to the other has the effect of trying to rotate the rings each time they scrape by and can hammer out the ring end locating pins.

For a given port width the more square and less round it is, the greater is the effective flow time / area, but the harder it is on the rings. Some aftermarket exhaust ports are severely squared out. A square across top is worse than on the bottom because of the relatively higher piston speed. Just a little more engineering and attention to detail would make them a much better product.

If the top and bottom of the ports have an arch to them the ring is gradually squeezed back in from each side of the port. With no arch the ring suddenly is brought up against the whole width of the port and tends to get slapped instead of eased back into the ring groove. Sometimes if they catch the ring snaps; sometimes the ring lands of the piston get shmucked or maybe both.

That sharp corner in port in the picture not only reduces the gradual squeezing effect on the rings, but because of the unbalanced shape from one side to the other has the effect of trying to rotate the rings each time they scrape by and can hammer out the ring end locating pins.

For a given port width the more square and less round it is, the greater is the effective flow time / area, but the harder it is on the rings. Some aftermarket exhaust ports are severely squared out. A square across top is worse than on the bottom because of the relatively higher piston speed. Just a little more engineering and attention to detail would make them a much better product.

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

woodyman

Addicted to ArboristSite

Except for smoothing and cleaning up and puting a bevel back on it looks very good,or I'm I wrong.

You need to make the sides of the port straight. The way they are you're only getting maximum width, and flow, at one small point. The sooner it can get to max width, the more it will flow.

Last edited:

Martinm210

ArboristSite Operative

Ports are looking good. Here is a diagram from Gordon Jenning's book. Note that the intake port does not need a rounded "TOP" as the rings never pass below the top edge.

The shape of the bottom edge does help prevent the skirt of the piston from snagging though, also makes the intake sound quieter.

The shape of the bottom edge does help prevent the skirt of the piston from snagging though, also makes the intake sound quieter.

Martinm210

ArboristSite Operative

This is also from Gordon's book on the proper way to chamfer the edges. Notice there is slightly more rounding given by the chamfering. This helps the rings gradually contract. He also notes a small amount of rounding at the edge to improve gas flow, but I'm not sure many folks actually do that.

Martinm210

ArboristSite Operative

Finally regarding size:

These are Gordon's suggested port time area numbers:

The cm3 is just the cylinder volume.

Seconds is determined by the port duration and RPM.

But looking at the numbers you can see that you want about the same intake and exhaust, if anything slightly more intake than exhaust time area and the transfer ports are a fair amount smaller.

This does depend on the port duration though, so if the intake and exhaust durations are very different then that would have to be figured into it.

For quick and dirty area, you can use spaghetti noodles and count them up.

These are Gordon's suggested port time area numbers:

For piston-controlled intake ports, 0.00014 to 0.00016 sec-cm2/cm3

For transfer ports……………….., 0.00008 to 0.00010 sec-cm2/cm3

For exhaust ports……………….., 0.00014 to 0.00015 sec-cm2/cm3

The cm3 is just the cylinder volume.

Seconds is determined by the port duration and RPM.

But looking at the numbers you can see that you want about the same intake and exhaust, if anything slightly more intake than exhaust time area and the transfer ports are a fair amount smaller.

This does depend on the port duration though, so if the intake and exhaust durations are very different then that would have to be figured into it.

For quick and dirty area, you can use spaghetti noodles and count them up.

timberwolf

Addicted to ArboristSite

Keep in mind those measurments are for bike sized engines, bevels on chainsaw ports will be smaller.

There is a down side to having too much bevel too, sure a round edge is better for flow, but a port that opens slowly with lots of restriction just bleads of pressure before the port fully opens and weakens the exhaust pulse.

You don't need bevel on the sides, this just widens the port from an unsupported ring width prespective without really increasing the flow capacity.

There is a down side to having too much bevel too, sure a round edge is better for flow, but a port that opens slowly with lots of restriction just bleads of pressure before the port fully opens and weakens the exhaust pulse.

You don't need bevel on the sides, this just widens the port from an unsupported ring width prespective without really increasing the flow capacity.

woodyman

Addicted to ArboristSite

Your are right as usual,but it still looks very good for not being just right.You need to make the sides of the port straight. The way they are you're only getting maximum width, and flow, at one small point. The sooner it can get to max width, the more it will flow.

Martinm210

ArboristSite Operative

Keep in mind those measurments are for bike sized engines, bevels on chainsaw ports will be smaller.

There is a down side to having too much bevel too, sure a round edge is better for flow, but a port that opens slowly with lots of restriction just bleads of pressure before the port fully opens and weakens the exhaust pulse.

You don't need bevel on the sides, this just widens the port from an unsupported ring width prespective without really increasing the flow capacity.

Thanks! I've been trying to just mimic what the saw already had. .080" is pretty big, it seems like I've been seeing something more like .040-.050" for the bevel.

One thing I thought was interesting was how the port itself is pretty flat on top, but the chamfer/bevel is slightly rounded. I guess that's one way to do it.

On a side note, what is the minimum recommended piston skirt width cover recommendation. I know you want to have enough to preven the skirt from falling into the port obviously, but what's a good target 2mm?

parrisw

Tree Freak

Thanks! I've been trying to just mimic what the saw already had. .080" is pretty big, it seems like I've been seeing something more like .040-.050" for the bevel.

One thing I thought was interesting was how the port itself is pretty flat on top, but the chamfer/bevel is slightly rounded. I guess that's one way to do it.

On a side note, what is the minimum recommended piston skirt width cover recommendation. I know you want to have enough to preven the skirt from falling into the port obviously, but what's a good target 2mm?

.075" I think, that's what I went to.

Lakeside53

Stihl Wrenching

Best thing is to mimic the factory bevel. It's way smaller than 75 thou...

parrisw

Tree Freak

Best thing is to mimic the factory bevel. It's way smaller than 75 thou...

I think he is talking about the skirt width to port edge clearance.

timberwolf

Addicted to ArboristSite

Best thing is to mimic the factory bevel. It's way smaller than 75 thou...

LOL, not if it's one of the ugly new Stihl 460s. Check out the side of the exhaust bttom right, it's like that all the way around the exhaust port.

Bevel is most importaint right in the center, near the sides it maters less. I like to taper starting with just a softening of the edges at the sides to likely .040 near the center of the port.

Last edited:

Erick

Addicted to ArboristSite

I think he is talking about the skirt width to port edge clearance.

:agree2:

and you want at a minimum 1mm or .040 but you also don't really want to go wider than 70% of the bore dia. I like to be a bit shy of "max" and remember measure twice cut once..... or in this case measure twice cut a little and then measure twice again.

Similar threads

- Replies

- 5

- Views

- 380

Want to Sell

Ported Stihl MS361 project

- Replies

- 4

- Views

- 1K