jimdad07

Addicted to ArboristSite

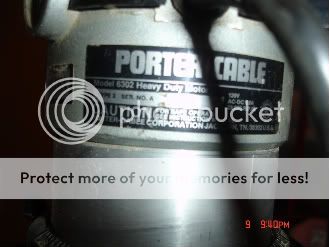

I was making a slab surfacer tonight and burnt my only router up that was worth a crap. Last winter I built my mother-in-law a new kitchen. I was using a 1/4" strait bit to make the groove for the shaker panels to fit into the door and drawer frames with the router set up on my home-made router bench. One of my bits broke in half and I never found the cutting head until tonight...:rant:...I took the router off of the bench and turned it right side up to router out the spot for the router base to fit into on the surfacer, I ran the router for about a minute when pieces of the fan blade shot out of the router and one of my shop GFCI's tripped :censored::censored::censored:. Took it apart and found the culprit:

Some how that little cutting head has lasted almost a year in that router without killing it. What sucks the most is that a lot of my woodworking is shut down now without my router until I can save up for a new one, it is the work horse in my shop.

Some how that little cutting head has lasted almost a year in that router without killing it. What sucks the most is that a lot of my woodworking is shut down now without my router until I can save up for a new one, it is the work horse in my shop.