Thanks for your help. I will go with the HDA-191 jet but I have another idea, assuming the goal is to block or close this hole in the jet. Since the current HDA-268 jet has a .58 mm opening which equates to .022835 inches, I could use a 0-80 2A screw with a maximum minor diameter of .0442 inches and effectively plug the hole. This would eliminate having to swap out jets and I've found JB weld doesn't hold up in constant gasoline contact. Since the jet is made from brass, a short 0-80 screw should easily thread into the hole.

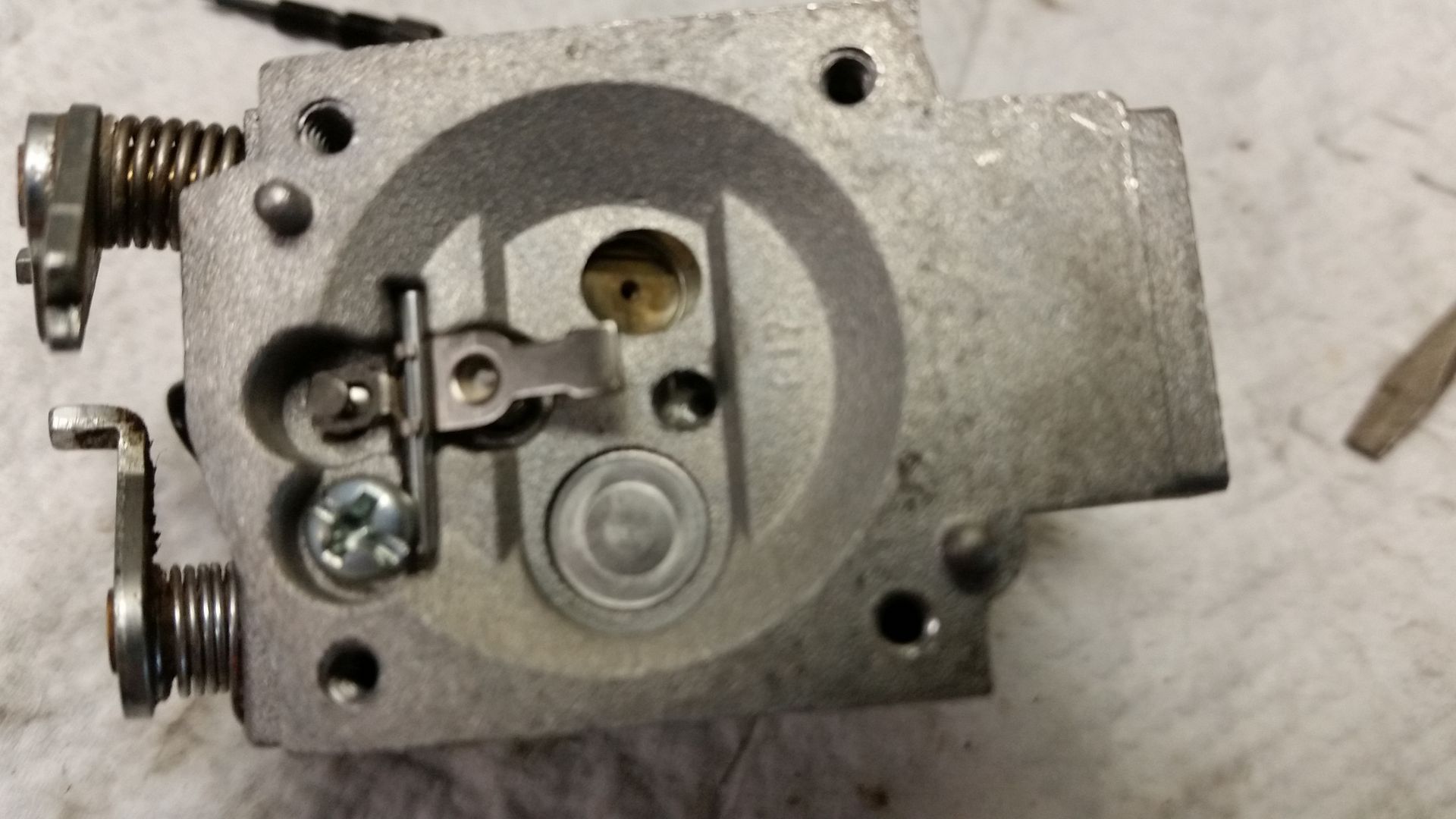

The goal is to block the hole in the bottom of the jet. The stock jet has to be in the correct position to line up with the feed hole in the carb body.

The 19X jet has a band machined and 2 feed holes to allow fuel flow regardless of the index. Just has to seat at the right depth, which has a bit of play as well.

Feel trying to insert a screw could allow debris to block the feed passage/damage the check valve.

Swapping the jet

Literally a 5-10 min job on the 590.

Remote AF cover/filter

Undo fuel/impulse

2 bolts (t27) to remove the carb

4 screws to remove bottom cover (metering/wet side).

Pin punch with flat face the jet into carb bore

Open throttle plate remove old jet

Tap in new jet

Reinstall.

Enjoy fully adjustable 590 carb