Well Gink, I'll just eschew giving the pictures any further exposure..

Hmmm, sounds like you are all bark! I think there is a reason you decline to show your craftsmanship and your self proclaimed mastery.

As to your request for homosexual gratification, I don't go that way, never have and ain't likely at my age to find your proposition entertaining. Thanks ever so much for your offer though...

Don't flatter yourself, it wasn't a real offer but more of reference, the last thing I need is some old man wanting to gum my sack.

In Re your link to ESAB, the portion I find pertenent is;

3.4.1.3The E6013 classification of covered mild steel electrodes was originally designedto have low arc penetration and flat smooth weld beads. These features allowed the electrodeto weld sheet metal. Today, many 6013 electrodes are used instead of 6012 electrodesbecause of the smoother arc, less spatter and more uniform weld bead surface.

A person with even dull/normal reading skills would note that ESAB proffers 6011 and 6012 primarily for the ability to run an open root pass, which is NOT the case being talked about in this post....

Hmmm, a open root pass you say, just out of curiosity why do you suppose that is? I say it is used on a open root pass because 6013 has a good quality of depostion and can fill gaps nicely, one feature it does have in it's favor, where 6010/6011 will struggle with filling the keyhole . But why do you suppose the cover pass is 7018 and not the almightly low penetration 6013?

I am rather conversant with ESAB consumables (that's rod & wire for nonweldors) and find their product highly acceptable. I also find ESAB to be quite generous in providing access to information on line....

I think you're rather conversant in the art of BS.

AWS Certified you say, am I supposed to be impressed by that? What was the name of your employer who paid to have you tested, and what process were you able to pass on? I had a lot of "Certified weldors" come through looking for jobs over the years.....

That what I say! As I will not say who my employer is here, I will say I work for a very large company that does strutural structures. I was qualified in a 1G position for flux core unlimited thickness and 2G .052 GMAW mig unlimited thickness.

I hired a 16 year old girl to weed the BSers out after I taught her to run stringers.

Sounds to me like she should have replaced you maybe you need to get ahold of that girl and ask her what she would use to weld structural steel with.

Do those stickers all over the helmet impress the dullards in your area?.

Not really sure if they do or not, then again I've never asked the question to anyone to see if it impressed them, I guess I like them and to me thats all that mattered, but just to clarify with you so you know my stance, I don't give a chit if you like them or not I think it's been obvious I think you are blowhard.

Little hard to tell from your picture but between that and your skilled verbiage expressing yourself you impress me as a bit wet behind the ears. Perhaps you should become an expert in residence on one of the multiple welding boards available till your Unemployment runs out. In the meantime, kindly employ Mr Jerk Off in deference to my age.

Yall go swill a nice 6pack now.

Thanks for the offer of the 6 pack but you can stick in your arse! I'm 36 years old and have worked for the same company for 12 years now. I've help multiple positions while being here and I'm not worried about my employment. I've never posted on any weld forum, I'll leave that to you.

You come on here acting like you know everything there is to know and try to bully me, go #### yourself. If you think I'll lay down for you, you are mistaken. Your information is incorrect and if you don't have the balls to admit it. Everyone here can read for themself and they can contact a qualified welder or CWI, Lincoln will even give you advice from their own in-house CWI on weld proceedures. So take it for what it worth and do your own research. There is good information and bad info, be wise with what you choose and from who you choose it from. Some guy on here claiming this and that but denies to show any proof of his capabilities is kind of strange to me. If I was on here doing the blowhard bit I'd at least back it up as I did.

Since this thread has gone to hell from us two arseholes I will extend a offer to the OP:

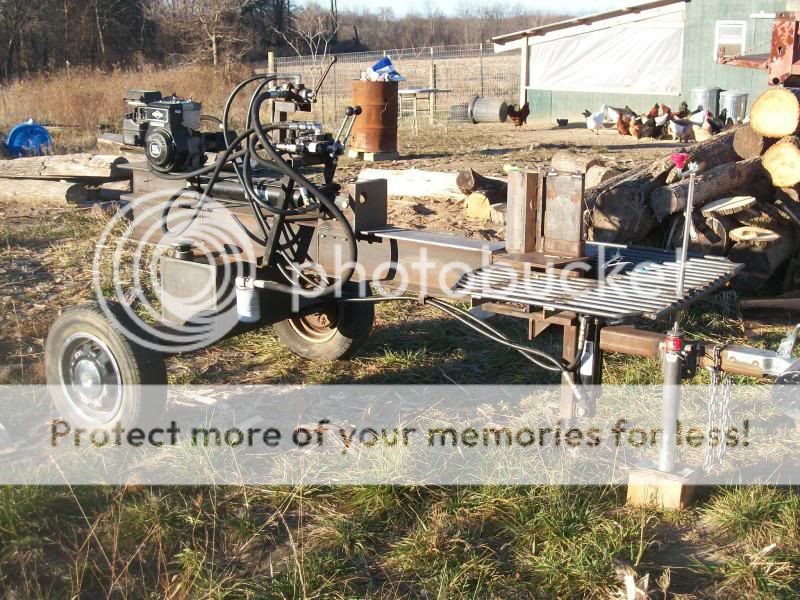

If you want to give me the dimensions of what you want as a 4-way I will make it out of my own material and ship it to you for no charge of anything!

I will also post here as I make it and show my method on how I do so. If you're interested PM me:hmm3grin2orange: