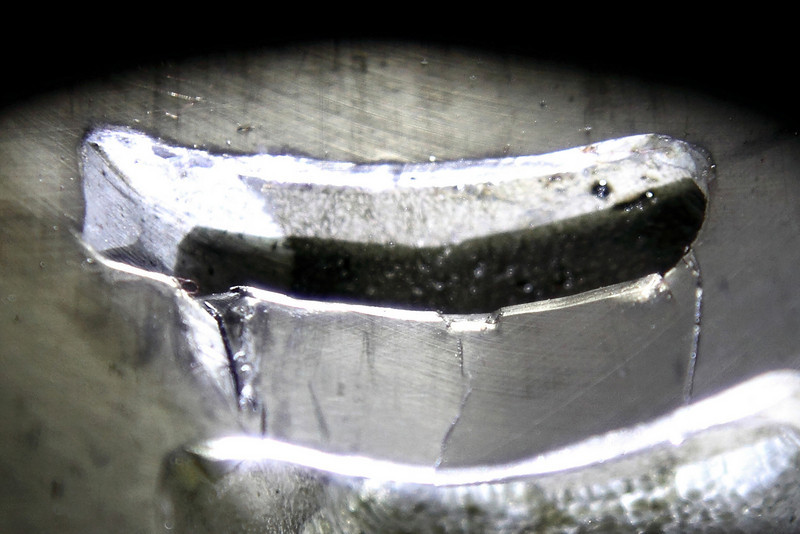

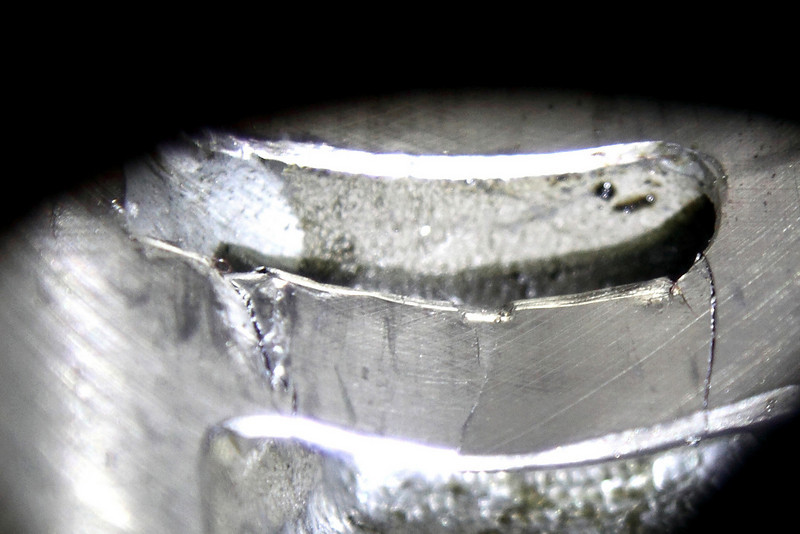

I should have posted this yesterday and after seeing the vid, it really looks like the chunk from the top of the piston happened first (see the compression lines? These happened as the top failed, not after), most likely as a result of the ring catching. So, the piston was on the down stroke when the failure started, popped the chunk off the top and broke the skirt, then the lower ring caught on the way up and broke that portion of the piston. I think you can see where one break is truncated by the other in the earlier pics, which indicates which happened first.

I think in the set of pics, that the ring snag is evident, as there is a v-shaped crevice that formed from a force in the direction of the "v", or on the downstroke. That should be where the ring caught the hardest and had the most force. This occurred on the downstroke, breaking the pin bosses. What I am not sure of with this is the displacement of the metal, as the side away from the "crevice" is lower, which suggested that the failure started on that side. However, the cracks that formed from the original impact may have allowed a lesser force to cause more displacement on the other side on a later stroke.

I think this is the same as what Tzed is saying, I just wish I had said it yesterday when I looked at this, but I wasn't confident enough to say it. I hadn't noticed the compression lines on the top of the piston before the vid, which was a very good quality.