You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Handle bar hose?

- Thread starter sachsmo

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

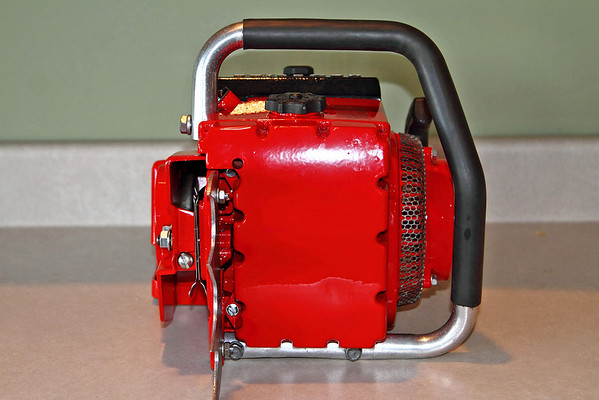

That is a clean 076 right there!!

Aren't you supposed to be putting a sled engine together or something

wse8562

ArboristSite Operative

That is a clean 076 right there!!

Yes and not a bad 1050 either!!!

$59.99 ($0.40 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$204.65

Oregon 295453/S Yukon+ Type A Class 1 (20 m/s) Chainsaw Protective Trousers, Black, 3X-Large

Express Shipping ⭐⭐⭐⭐⭐

$56.99 ($0.38 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

Brad, that stuff looks like it would work good.

I need some for a 306SA i'm restoring, and I think I'll check out some local electrical supply house first to see if they carry it. I'm betting they will.

I need some for a 306SA i'm restoring, and I think I'll check out some local electrical supply house first to see if they carry it. I'm betting they will.

bobt

Addicted to ArboristSite

Hey Brad,

Is that shrink tube a plastic material that is rigid or maybe "stiff" ?

Is it pretty slippery when all is said and done?

What size did you start with when doing those handles?

I found some at my local auto parts store in 1.1" diameter by 9.5" length. I couldn't get any longer than that. It actually should be longer, but it is what it is. I used it on my old 041, and I had one heck of a time to get it to bend around the 041 handle. After pushing and tugging, I finally got it to where I was satisfied, but the tubing was all kinked on the inside of the bend. I didn't think it would shrink down smooth, but I carefully used my propane torch on it, and lo and behold the darn stuff shrunk down and smoothed out the kinks. It looks right fine now, but I wish it were longer. It is slippery though, not tacky like a rubber hose would be.

Bob

Is that shrink tube a plastic material that is rigid or maybe "stiff" ?

Is it pretty slippery when all is said and done?

What size did you start with when doing those handles?

I found some at my local auto parts store in 1.1" diameter by 9.5" length. I couldn't get any longer than that. It actually should be longer, but it is what it is. I used it on my old 041, and I had one heck of a time to get it to bend around the 041 handle. After pushing and tugging, I finally got it to where I was satisfied, but the tubing was all kinked on the inside of the bend. I didn't think it would shrink down smooth, but I carefully used my propane torch on it, and lo and behold the darn stuff shrunk down and smoothed out the kinks. It looks right fine now, but I wish it were longer. It is slippery though, not tacky like a rubber hose would be.

Bob

Trigger-Time

Addicted to ArboristSite

McMaster Carr has all kinds, so does Fastenal (quite pricey)

I would rather have the hose with ridges though.

I'm sure Stihl and the others buy theirs somewhere?

You can get it from a Stihl dealer.

Thats where I got this piece.

Dealer said he would show me how to put it

on when I was ready, with soapy water and air hose.

TT

Last edited:

bobt

Addicted to ArboristSite

You can get it from a Stihl dealer.

Thats where I got this piece.

Dealer said he would show me how to put it

on when I was ready, with soapy water and air hose.

TT

You don't need soapy water, but you sure need the air hose,,,,,,,,and A SECOND PAIR OF HANDS. It works slick.

Put the handle in a vise. Start the hose on the handle. Then pinch the end of the air gun in the other end of the hose. Have your helper hold the hose on the handlebar and have him pull it over the tube as you apply the air. The air inflates the hose enough so that it is pretty easy to get it on. If you have cut the hose to the needed length before hand, the last bit gets tricky, as you have to pinch the air gun between the handle and the hose.

Bob

1steve

ArboristSite Guru

stihl handle hose installation

check this thread out, might help http://www.arboristsite.com/chainsaw/47131.htm

http://cgi.ebay.com/ROLL-STIHL-RUBB...aultDomain_0&hash=item230cc30c05#ht_500wt_922

check this thread out, might help http://www.arboristsite.com/chainsaw/47131.htm

http://cgi.ebay.com/ROLL-STIHL-RUBB...aultDomain_0&hash=item230cc30c05#ht_500wt_922

Last edited:

Waggie

ArboristSite Lurker

Fitting Genuine Stihl handle bar hose

I have just fitted a new original handle hose, and whilst it wasn't easy I don't think it was hard, and the finish is SUPERB.

I don't have a compressor so this is another method, and it worked a treat from me.

How I fitted this hose, Firstly you have to select the correct size for your saw (there are 4 sizes I used 3/4" for 08s and S10 saws). then using very hot water soaked the hose for about 10 - 12min (making it very pliable), then offering it on to the tube the first couple of inches just slide on, then using a red plastic glove (to aid grip) you use a rotating and sliding motion at the same time,(this will slide about 1/2" of tube per motion) continue going until the full length of the fitted hose. The results are well worth the effort.:msp_smile:

I have heard Stihl sells the stuff. Is there any where else to source good thick hose?

I have just fitted a new original handle hose, and whilst it wasn't easy I don't think it was hard, and the finish is SUPERB.

I don't have a compressor so this is another method, and it worked a treat from me.

How I fitted this hose, Firstly you have to select the correct size for your saw (there are 4 sizes I used 3/4" for 08s and S10 saws). then using very hot water soaked the hose for about 10 - 12min (making it very pliable), then offering it on to the tube the first couple of inches just slide on, then using a red plastic glove (to aid grip) you use a rotating and sliding motion at the same time,(this will slide about 1/2" of tube per motion) continue going until the full length of the fitted hose. The results are well worth the effort.:msp_smile:

I have just fitted a new original handle hose, and whilst it wasn't easy I don't think it was hard, and the finish is SUPERB.

I don't have a compressor so this is another method, and it worked a treat from me.

How I fitted this hose, Firstly you have to select the correct size for your saw (there are 4 sizes I used 3/4" for 08s and S10 saws). then using very hot water soaked the hose for about 10 - 12min (making it very pliable), then offering it on to the tube the first couple of inches just slide on, then using a red plastic glove (to aid grip) you use a rotating and sliding motion at the same time,(this will slide about 1/2" of tube per motion) continue going until the full length of the fitted hose. The results are well worth the effort.:msp_smile:

Very nice job you did there and another successful method of installing it. I have done quite a few of mine but still use the air assist method, may give yours a try on the next install.

A quick-and-dirty option that works: pipe insulation that you can buy at any home improvement center that costs practically nothing. One of my good friends threaded that onto the handle of his Stihl 041 Farm Boss this way, and it works. He liked the extra cushioning because those old saws vibrate like Sherman tanks.

sachsmo

Addicted to ArboristSite

They use peristaltic pumps at work for pumping ink.

Every color change they change out the hose, had the girl that operates the printer save these "castoffs".

They work great although the hose doesn't have ribs it is pretty thick and after the KY drys they don't slip or twist.

It took a good supply of 80 psi air and a quick hand over hand, but the results speak for themselves;

Every color change they change out the hose, had the girl that operates the printer save these "castoffs".

They work great although the hose doesn't have ribs it is pretty thick and after the KY drys they don't slip or twist.

It took a good supply of 80 psi air and a quick hand over hand, but the results speak for themselves;

SkippyKtm

The Lorax, my FIL rip...

Here's the rig I use and some of the hose I have. Generally I need around 20 to 30psi and some soapy water to get them slid on. You want to leave a few inches extra and trim it after...

SkippyKtm

The Lorax, my FIL rip...

I needed one for a half wrap 084 handle. I took the full wrap one that had been cut on. Sprayed wd40 inside it repeatedly and kept a 360 rotation till I had it off.

Then had to do the same thing to put back on the other handle. Had handles mounted in a vise the whole time and just used my hands to twist.

Then had to do the same thing to put back on the other handle. Had handles mounted in a vise the whole time and just used my hands to twist.