briantutt

Addicted to ArboristSite

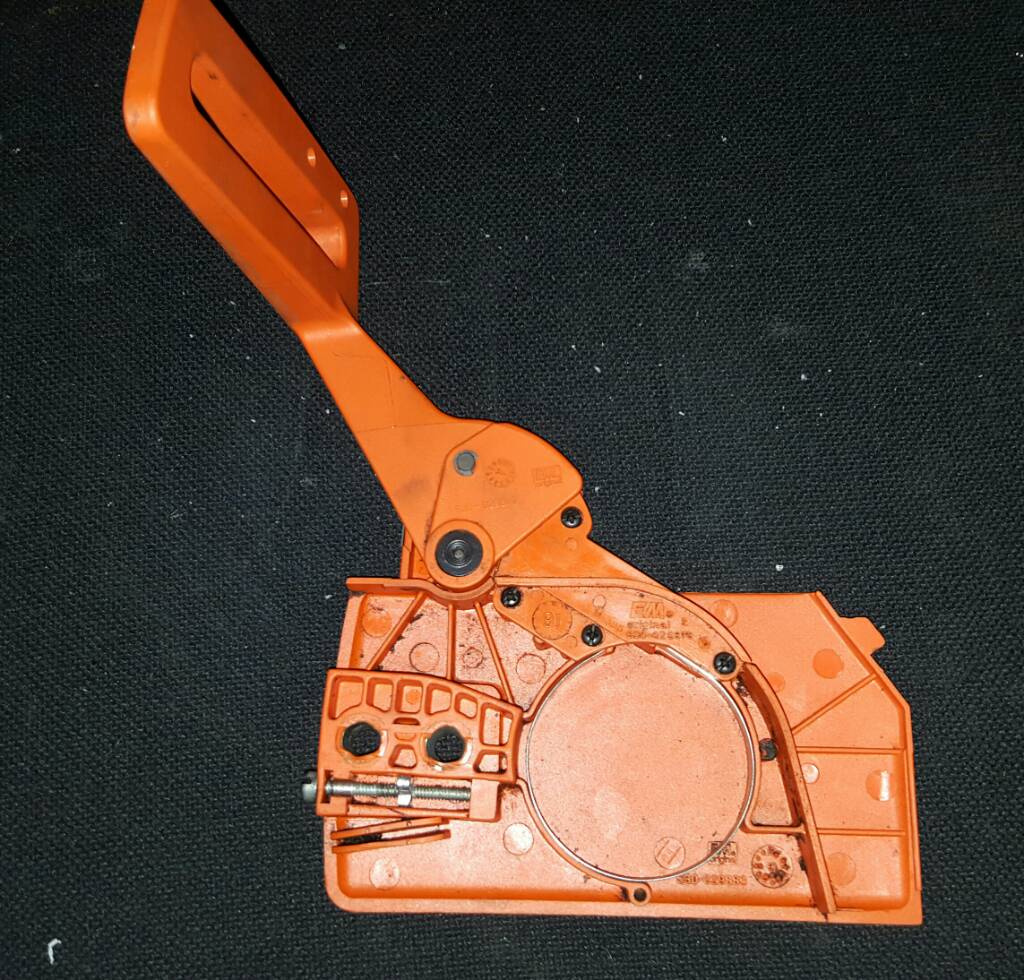

Got my knock off muffler today. Came in a Farmertec branded bag like the bar nuts did. Pipe is smaller than I imagined it would be. Don't you want a cross section area bigger than exhaust port in the cylinder? There is no baffle plate or anything inside.

Brian