Here's where I'm at guys.

I'm not sure which set of numbers I don't like the most.

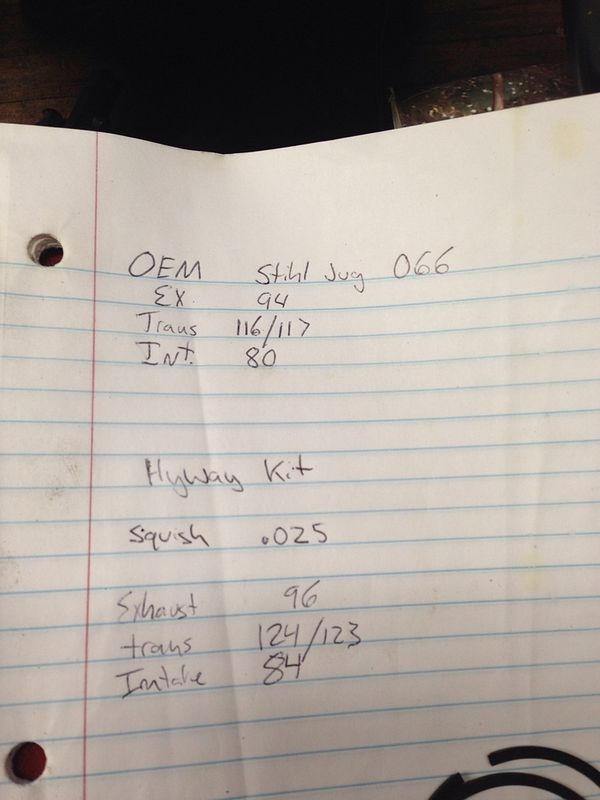

The OEM jug has really high transfers for a 66. Highest I've seen. I checked it several different times, made sure the wheel was zeroed several times, and got the same thing each time.

The highway jug has a lower exhaust, which is a good thing, lower transfers, which I like on the 66, but the intake is crap. Way too low for my liking. Some folks say it doesn't hurt a 66, but I don't like it.

Here is the OEM making a few cuts. 28" 8 pin rim.

[video=youtube;YqrTGIlgTe4]http://www.youtube.com/watch?v=YqrTGIlgTe4&list=UUvEG38T8e7zTVuj5qqvYPQQ&index=1[/video]

This saw was the "Stumping Saw" for a tree service in Salem, VA and has been rode hard and put up wet. I've already helicoiled both muffler bolts in the case, and it has a helicoil for one jug bolt, and I stripped another, so it'll have to be helicoiled before I can run the hyway kit any.

Factory jug had carbon buildup that was .032 thick!! Makes ya think twice about .020 squish

And .010 on the crown.

Back to the hyway kit. JJ nailed it in his first post. Once I slid the piston up in it, it became evident the roof was extremely flat. Hard to tell looking down the bore. The rings slide past it, and I don't feel any resistance from it, and will give it a go as is...u know...for science and all.

So there's where I'm at. Gotta pull it back down, helicoil the jug bolt and slap it back together. Might be a day or two.

And yes Young, I know, I'm slow....