You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Inside the 372XP X-TORQ

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Do you guys want the good new, or the bad news first?

Tzed250

Addicted to ArboristSite

.

You made a drink mixer/blender out of it...

.

You made a drink mixer/blender out of it...

.

Let me guess, the saw ran good, the video is junk.Do you guys want the good new, or the bad news first?

.

You made a drink mixer/blender out of it...

.

Actually, I'd like to see an X-torque ice cream maker...

$39.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$14.99

$17.99

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15" Blade with Woodzig Chainsaw-Style Tooth Design

AMZ South Supply

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$19.99 ($3.33 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

$56.99 ($0.38 / Foot)

$59.99 ($0.40 / Foot)

Double Braid Arborist Rope Orange(1/2 in x 150 ft) Arborist Rigging Polyester Rope - 48 Strand Rope Swing for Tree Bull Rope for Outdoor, Climbing, Swing, Sailing

Cosirulnta Shop

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$59.99 ($0.40 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$56.99 ($0.38 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

Tzed250

Addicted to ArboristSite

Actually, I'd like to see an X-torque ice cream maker...

I would definitely buy one of those!!!

.

The bad ,,,

To put it mildly, I'm not a happy camper. In this line of work, it's bound to catch up to you sooner or later. I just blew up my first customers saw

Here's what caused it. As a general rule of thumb, you never mess with the bottom of the exhaust port. In this case, the port bottom was too flat for as wide as I made it. On the bright side, there is litterally at least 1/4" of piston skirt below the exhaust port when the piston's at TDC. By the time I have the port shaped like I want it, the place where the ring snagged will be completely gone. I got soooo lucky. I'm also super thankful this happened to me now, and not after I shipped it.

I'm trying to make contact to order a new piston, and will pay for next day shipping. If need be, I'll next day air the saw to it's owner, who needs it for a job starting next Friday. I've already talked to him, and thank goodness, he was gracious about it.

You've got to figure something like this will happen sooner or later, but that doesn't make it any easier when it does. I'm sure I'll catch some flack from this for a select few, but I've always been open, and hopefully someone besides me will learn from it. I'm not here to hide anything, so you get to see the good and the bad.

Here are the pics. I'm currently uploading the vid of the saw cutting Oak.

Tzed250

Addicted to ArboristSite

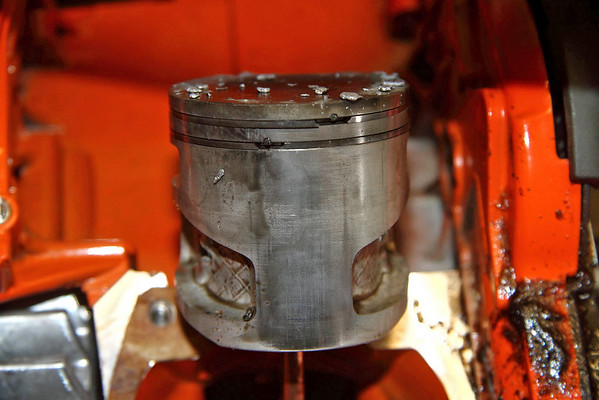

To put it mildly, I'm not a happy camper. In this line of work, it's bound to catch up to you sooner or later. I just blew up my first customers sawYup, you read that right. I put nearly a tank of fuel through the saw, and it ran perfectly. But I thought there was more in it, brought it home, gave it a few degrees if ignition timing advance, and was tuning it. It was at WOT and IT happened! The bottom ring snagged on the bottom of the exhaust port, and busted out the crown of the piston. I immediately yanked it apart. To my amazement, the cylinder is fine.

Here's what caused it. As a general rule of thumb, you never mess with the bottom of the exhaust port. In this case, the port bottom was too flat for as wide as I made it. On the bright side, there is litterally at least 1/4" of piston skirt below the exhaust port when the piston's at TDC. By the time I have the port shaped like I want it, the place where the ring snagged will be completely gone. I got soooo lucky. I'm also super thankful this happened to me now, and not after I shipped it.

I'm trying to make contact to order a new piston, and will pay for next day shipping. If need be, I'll next day air the saw to it's owner, who needs it for a job starting next Friday. I've already talked to him, and thank goodness, he was gracious about it.

You've got to figure something like this will happen sooner or later, but that doesn't make it any easier when it does. I'm sure I'll catch some flack from this for a select few, but I've always been open, and hopefully someone besides me will learn from it. I'm not here to hide anything, so you get to see the good and the bad.

Here are the pics. I'm currently uploading the vid of the saw cutting Oak.

There are two kinds of engine builders Brad....Those that have blown engines, and those that will blow engines...just part of the game.

.

Let me guess, the saw ran good, the video is junk.

I wish!!!

There are two kinds of engine builders Brad....Those that have blown engines, and those that will blow engines...just part of the game.

.

I realize that, but that doesn't make it any easier. Then you add to the fact that I'm sharing my work, and it doesn't make for a fun day! This is the very first customers saw I've blow up. I did go through a couple topends on one of my personal saws before I got it right. But it's not such a big deal when it's your own saw.

And now for the good news. The saw was holding 11,500 in the cut, with the bar buried in hard Pin Oak.

<object width="480" height="385"><param name="movie" value="http://www.youtube.com/v/eiQLdfFSl20?fs=1&hl=en_US&rel=0"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/eiQLdfFSl20?fs=1&hl=en_US&rel=0" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="480" height="385"></embed></object>

<object width="480" height="385"><param name="movie" value="http://www.youtube.com/v/eiQLdfFSl20?fs=1&hl=en_US&rel=0"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/eiQLdfFSl20?fs=1&hl=en_US&rel=0" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="480" height="385"></embed></object>

Tzed250

Addicted to ArboristSite

I realize that, but that doesn't make it any easier. Then you add to the fact that I'm sharing my work, and it doesn't make for a fun day! This is the very first customers saw I've blow up. I did go through a couple topends on one of my personal saws before I got it right. But it's not such a big deal when it's your own saw.

You lucked out big time!! It blew up on the dyno instead of at the track...

As long as the man gets a good work saw it's all good...

.

As long as the man gets a good work saw it's all good....

There's only one way to handle something like this. I got his phone # and gave him a call. It's not fun facing the music, but it's the only way.

HARRY BARKER

ArboristSite Guru

ouch

CentaurG2

Addicted to ArboristSite

As we say in the tree biz, looks like it is going to be a not for profit job. Happens, but insurance usually covers it.

The port is properly shaped now and good to go. If I had a new piston, it'd be running in 1/2 hour or less. Anyone have a PN for a 372XP X-TORQ piston?

Tzed250

Addicted to ArboristSite

The port is properly shaped now and good to go. If I had a new piston, it'd be running in 1/2 hour or less. Anyone have a PN for a 372XP X-TORQ piston?

http://weborder.husqvarna.com/order_static/doc/HIPL/HIPL2010/HIPL2010_30.pdf

510 44 39-02

Last edited:

Thanks John. The piston's not in the system where I normally order Husky parts. Neither is the P&C kit. I'm hoping Spike can help me out with a piston on Monday.