Ummmmmmmmm; if you slip a preceding Half Hitch off the end of a spar, it melts to nothing, for it is just a loop crossing itself. But, if you slip a Marl off the end of a spar, it doesn't just melt to nothing whenst you pull the ends, but rather an OverHand Knot is left in the line. The Half is simpler to do, simpler to undo etc. but less secure, but probably deforms line less so is probably statically stronger, but also allows more slip friction conversions of impact force to heat to possibly be stronger in dynamic conditions as well. The Marl is more secure,takes more time to set properly, but the left over Overhand in the line can sometimes get in the way, but; can also be returned to climber thru pulley quicker> without fear of line running out of pulley(knot stops it), especially if has a slip in it too if lying way high and fast (to keep from 'jamming' or at least less frustrating..). It jest depends on what ya need.

To further confuse things, if you make a Half Hitch like not a preceding Half, but rather like the first pic in Metals046 line drawing.......and pull it from each end; it inverts to a Marl, for this type of Half Hitch does leave an Over Hand Knot in line if slipped off the end of the spar!

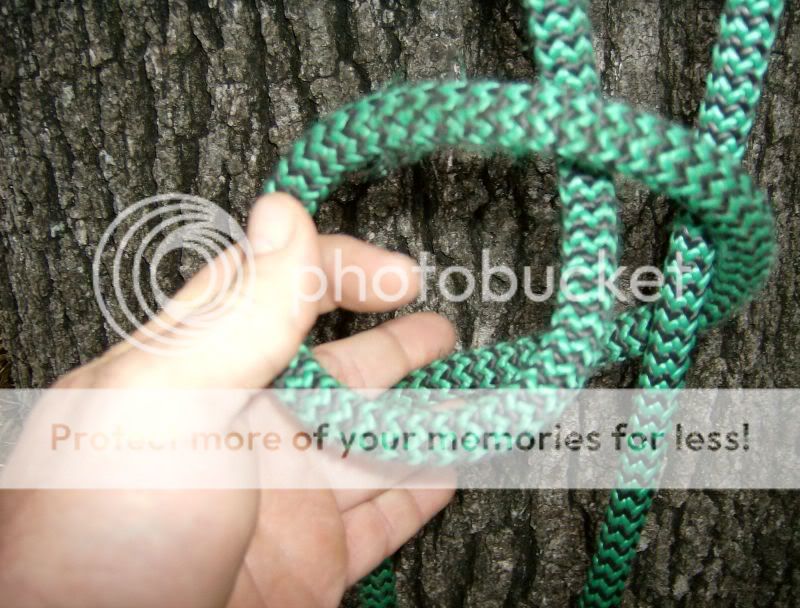

Speaking of which, it is best not to start a timber like this(Half Hitch, whereby after making the eye around the Standing, you immeidately go under the line-at the point of least 'pinch'), but rather crossing over, then under to start 'loose braid/ temporary eye splice' to secure. This reduces the line tension by friction of contact and pinch, before the first trapping of the line; and then also places that first trapping/'nipping' of the line further away from the 'teepee' that gives least security. Each Turn gives more friction reduction to line tension (to trap easier) and then until you come around half way (inline with Standing Part) where figuratively the most 'pinch'/ trap/ 'nipping' of the line is (assuming all contacts on convex locations on spar).

5 Tucks on Timber isn't required, just suggested, but would give significant friction reductions, and travel to hopefully firm final pinch/nip to secure.

Strength(retention)wise, it is best to take a Round Turn, rather than a Simple Turn around the Standing Part. Anything bends/deforms the Standing (leading to 'capacity loss' because line can only support on the inline axis, not on the cosine/across axis, so is 'strength' is reduced or forces leveraged higher that are carried within the rope device ). This (Round Turn) strategy can work against ya, if the direction of the pull changes, because the system then can't self adjust to minimal forces as well (ie slide around as easily to be inline with changing pull direction).