Really fun watching this all come together.

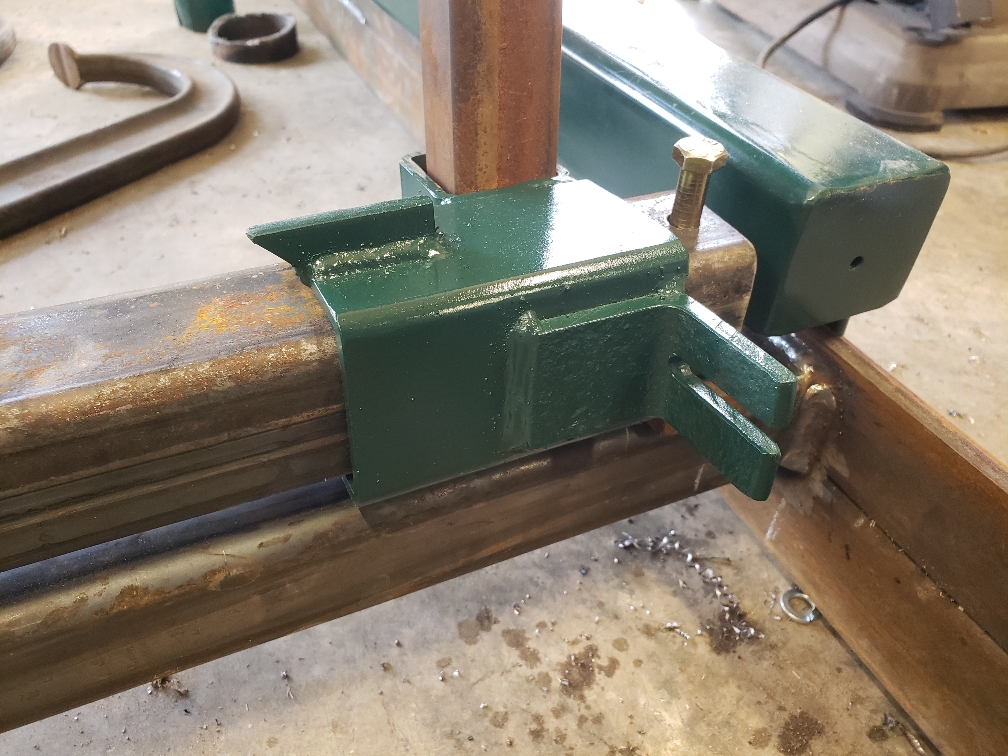

The color looks close to British Racing Green, so this will certainly make it faster

The color looks close to British Racing Green, so this will certainly make it faster

Maybe it would work better if you used a different color grease Bob lol.Here you can see the new grease partway trough the bearings in pink.

Hi Bob, my mill utilizes roller guides with sealed bearings.Thanks

What sort of guide bearings/blocks will you be using?

Ours came with a simple down pressure home made Hardwood guide block setup

View attachment 971569

However, amongst the parts box were the 2 rollers, one each side. I tried using them, but they kept getting clogged with sawdust and seizing so we went back to the wooden blocks - they work OK sort of but I wonder if they have improved on the rollers?

I modded and replaced the bearing bolt with a home made hollow bolt with and grease nipple, external spacer (1) internal space (3) to see if I could regularly blast the dust out of the bearing with a grease gun but still no good.

View attachment 971571

Here you can see the new grease partway trough the bearings in pink.

I'm going to try this again with sealed bearings.

Orange is spacer 3, Blue is spacer 1.

View attachment 971572

Thanks, I hope I can keep up the pace to keep guys interested!Really fun watching this all come together.

The color looks close to British Racing Green, so this will certainly make it faster

That may not be a bad idea. Also some "bearing" greases may not cut it at those high speeds and loads. At 5000 feet per minute blade speed, a 3" diameter roller is running 6400ish RPM, a 2.5" roller at 7640ish RPM, and 2" roller at 9550ish RPM. Have you tried a high quality bearing? Different grease? Shielded bearings? I used to buy shielded bearings for another application but basically the same setup that would be submerged repeatedly in water and mud. I would pull the inner shield and drill a tiny grease purge hole in the outer shield. Helped increase the bearing life immensely.Maybe it would work better if you used a different color grease Bob lol.

Nice job on that, odd it isn't working well for you.

Wonder if its because of the very fine dust off your extremely hard woods.

Thanks very much for that info and it all makes sense - I will try with some sealed bearings.Hi Bob, my mill utilizes roller guides with sealed bearings.

This page shows the components on the Linn Lumber mills.

https://www.linnlumber.com/partsandaccessories.htmlThanks, I hope I can keep up the pace to keep guys interested!

That may not be a bad idea. Also some "bearing" greases may not cut it at those high speeds and loads. At 5000 feet per minute blade speed, a 3" diameter roller is running 6400ish RPM, a 2.5" roller at 7640ish RPM, and 2" roller at 9550ish RPM. Have you tried a high quality bearing? Different grease? Shielded bearings? I used to buy shielded bearings for another application but basically the same setup that would be submerged repeatedly in water and mud. I would pull the inner shield and drill a tiny grease purge hole in the outer shield. Helped increase the bearing life immensely.

I hate to be the bearer of bad news,, but, there is a 99% chance that the very fine sawdust BobL produces is the cause of the bearing failures.

I worked for a company that built VERY high voltage (6,000 volts) and pretty high amperage distribution cabinets and we used a fiberglass type material to make brackets and supports for the copper bus bars..

The material came to us like sheets of plywood, except it was sheets of glass mat, instead of wood.

Rather than sawing, and drilling, someone saw a CNC router that was designed for wood.

It had six spindles, and ran like 20,000 rpm. They installed the machine, (this was about a $250,000 machine.)

The 1" (25mm) thick fiberglass routed beautifully,, EXCEPT,, the dust was VERY fine.

Within two weeks, all the spindles were destroyed.

The company even built a new design "air seal" that used large amounts of compressed air to try to keep the dust away from the bearings.

That failed.

It turned out that the ONLY thing that would help was slowing down the spindles.

To save the bearings in the spindles, a 50% reduction of speed was required.

We ended up having to buy a second machine,, to keep up with production demands.

Ultra fine dust is REALLY hard to keep out of bearings,,,,,,,,,,,,,,, changing the type bearing seal may not help.

The fiberglass board is red in color,,I work with systems from 345,000 volts AC right down to 5 volts DC and am very familiar with the insulating board you describe. Nasty stuff for sure when you cut it.

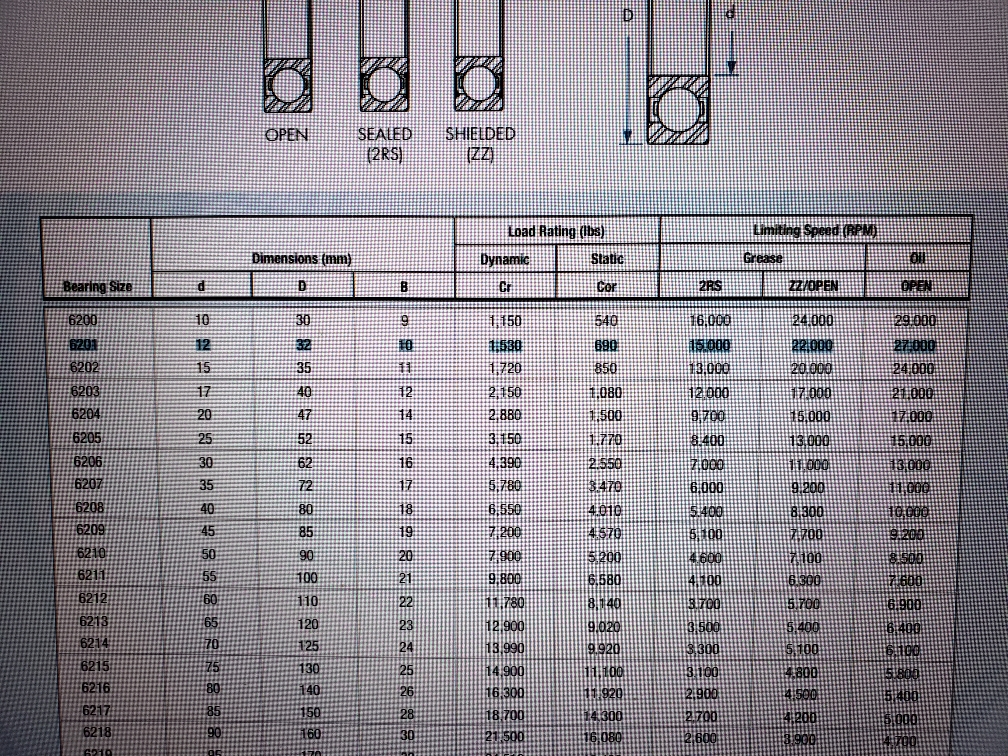

I was wondering about that also. Too much moment load caused by the back of the band riding on the roller guide wheel flange will prematurely wear bearings. Especially in this application where the bearings are quite small to begin with and are certainly not designed for such loads.Thanks for the info OH_Varmntr. The bearings in our mill rollers are exactly the same number as yours.

Unfortunately I can't reuse the old bearings as sealed bearings because I have removed both the seals from the inner bearings, and removed the inner seal and drilled small holes in the outer seal of the outer bearings to let the grease through.

Re: DUST Comments

Thanks for the info on the fine dust and bearings.

The thing was that when I used the grease purging method, dust in the bearings was not a problem.

The bearings still turned turned fine after cutting but the bearings and rollers got hot which is why I now suspect the grease?

FWIW while cutting we use a decent stream of cooling water both above and below the blade so there's not much fine dust floating around but theres a lot of sawdust mud.

I contacted Linn Lumber about this and within 12 hours I received a detailed reply from Chris King. I was really impressed that he replied to the operator of a 20 year old Linn Lumber kit mill. He mentioned that they supply rollers with both sealed and greased bearings but unfortunately did not provide any answers about the type of grease. He suspects the back of the back of the blade might have been too close to the back rim of the roller - he recommended an 1/8" gap - I cant remember what we used.

I have sent him a couple of more questions about setup and hopefully he will reply.

I'm going to try new sealed bearings and see what happens.

Thanks again to everyone who replied.

I just picked up some new sealed NSK bearings from our local (2.5 miles away) bearing store - US$14 for 4 so if they don't work out it's not going to break my bank account. It's going to be a while before I can get down to the milling yard to try them out as we're tied up for the next few days.I was wondering about that also. Too much moment load caused by the back of the band riding on the roller guide wheel flange will prematurely wear bearings. Especially in this application where the bearings are quite small to begin with and are certainly not designed for such loads.

I'm looking forward to hearing results of your experiments with your mill!

Sent from my SM-G960U using Tapatalk

Those stops are are not really for holding logs but for thinnish billets or cants which means they can also be very small.I was hoping to make some headway tonight but I've run into a big of a snag for now. While mocking up the bunks and laying out the log stops I noticed if placed where the print shows, the log will be clamped too far towards the axle of the fixed band wheel and will contact the band wheel and fixed roller guide.

Thats good to hear Bob! I'm not a chemist or anything, just a lowly electrician. I learned the hard way about mixing grease in motors and other expensive gear with precision bearings to know you have to use the right stuff.I received further Information from Chris at Linn Lumber about the rollers. He said my "flow through grease" roller mod should work fine but high speed grease should be used. I found out from a machinist that the Blue grease I used would be too viscous for the bearing speeds involved and I should be using a Bentonite based (brown or tan) bearing grease.

Enter your email address to join: