Looking really Nice !

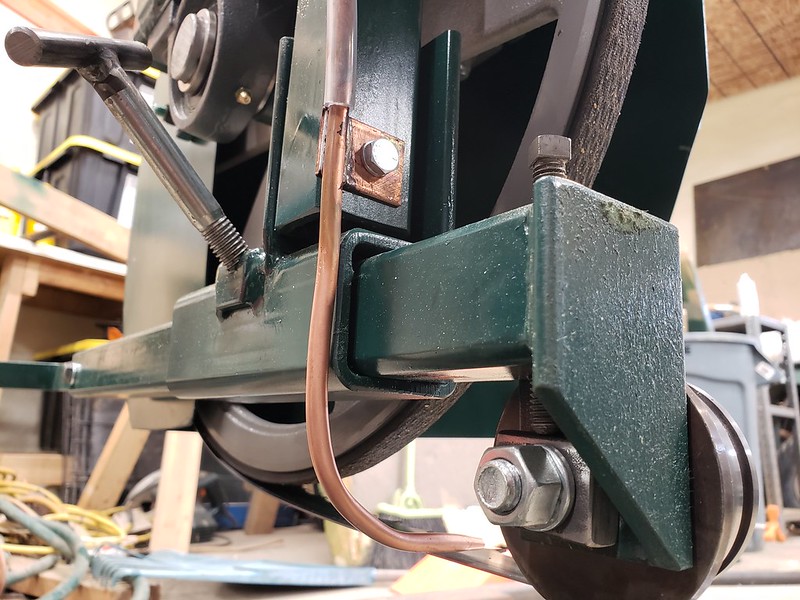

I couldn't tell if you were running any water cooling or not?

Thanks heaps for teh pictures and vids - very useful to me

Some suggestions:

Move the throttle to the side of the mill frame so you don't have to climb over the bunks as you mill.

Add some carriage stops at both ends

Turn the blade tension pressure gauge so you can see it while running. If for some reason the pressure starts to drop you can see it and stop before the blade comes off

Your build has given me the impetus to start a rebuild of our Linn mill.

One thing I can see from your vid is I need to remake the infeed roller support - the previous owner had chewed this out to get extra range of adjustment - who knows why this was needed but he also put shims under the follower wheel bearing supports presumably to level the blade between the wheels but I think he might have been chasing his tail. Anyway its a mess. I will start a new mill refurb threadd so as not to clutter up your terrific build story..