I think you might be right, an adjustable 4 way it is! I get such a mix of wood, some as large as 3' across and some 8"-12". I have a buddy that has a log yard and gives me butt ends every now and then.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Log splitter questions/opinions

- Thread starter dave_dj1

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

farmboss45

ArboristSite Operative

An adjustable wedge is the way to go, IMO. I made a slip on one for my splitter and hardly use it. If the wood was all the same size, it would be great, but no two pieces are the same diameter.

My knife is 12 inches tall, and the 4 way is centered on the knife. Thats okay for 12 inch wood but not okay for 20 inch wood.

Ted

Hey Ted, Michael here, I would like to check out your slip on design, every once in a while, a 4 way might come in handy, besides. I like a good project to keep me out of the wifes sight!

Well I made some progress this afternoon, I'll get some pics up tomorrow evening. I have the axle assembly pretty much ready to go, put the beam, tank, cyl, and motor on for mock up, looks good so far. Now I am going to research log lifts and outfeed tables.

HCB7077

New Member

There are many things I would recommend for you to consider.

1) rpm output of your engine and input rpm of your pump. If the engine runs slower than your max rpm of the pump you might want to gear it up. A 16 gallon/ minute pump will not flow 16 if it is running too slow.

2) oil, the higher flow of oil the more you are working it which means the hotter the oil will get so you will want to look at the volume of oil tank capacity or oil cooling if your pump flows more oil than can cool in the tank.

3) I don't know what size of timber you get into, having the ability to use your splitter in the vertical position is very nice on bigger logs because when you split it stays right there and you just spin the log and take another stab at it.

I just built a log splitter this summer and finished about a month ago. My equipment is a 28/ gallon minutes pump driven by a 4 cyl Wisconsin engine. I double v belt pulley drove it to gear up the rpm into the pump so I would only have to run the engine at 1/2 throttle and still have a fast cycle time. It is fast enough to keep a friend and I completely busy splitting wood. I can try to post some pics tonight if you would like.

Also I bought most of the supplies I was not able to beg borrow or steal from surpluscenter.com they have a great selection and very fair prices and fast delivery.

1) rpm output of your engine and input rpm of your pump. If the engine runs slower than your max rpm of the pump you might want to gear it up. A 16 gallon/ minute pump will not flow 16 if it is running too slow.

2) oil, the higher flow of oil the more you are working it which means the hotter the oil will get so you will want to look at the volume of oil tank capacity or oil cooling if your pump flows more oil than can cool in the tank.

3) I don't know what size of timber you get into, having the ability to use your splitter in the vertical position is very nice on bigger logs because when you split it stays right there and you just spin the log and take another stab at it.

I just built a log splitter this summer and finished about a month ago. My equipment is a 28/ gallon minutes pump driven by a 4 cyl Wisconsin engine. I double v belt pulley drove it to gear up the rpm into the pump so I would only have to run the engine at 1/2 throttle and still have a fast cycle time. It is fast enough to keep a friend and I completely busy splitting wood. I can try to post some pics tonight if you would like.

Also I bought most of the supplies I was not able to beg borrow or steal from surpluscenter.com they have a great selection and very fair prices and fast delivery.

I ordered the pump adapter this morning from surplus center, I need it to determine placement of the engine.

HCB7077, I hear ya, my motor will turn 3600 all day. Vertical splitting for me is no good, my back couldn't take it. A good pickeroon or something will assist in getting them on the log lift. thanks for your input. I have very little money in this thing right now. Maybe 375.00 including the new motor. I am becoming a much better scrounger...LOL

The only thing left to order is the pump and lovjoy connection and valve. I'm still undecided on pump size, maybe I should just go with the 16 gpm and be happy with 11 sec cycle times and not have to worry about not having enough power to properly power the 22 gpm pump. I would like to do the 22 gpm though as I have been talking this thing up to my brother for a while...lol.

HCB7077, I hear ya, my motor will turn 3600 all day. Vertical splitting for me is no good, my back couldn't take it. A good pickeroon or something will assist in getting them on the log lift. thanks for your input. I have very little money in this thing right now. Maybe 375.00 including the new motor. I am becoming a much better scrounger...LOL

The only thing left to order is the pump and lovjoy connection and valve. I'm still undecided on pump size, maybe I should just go with the 16 gpm and be happy with 11 sec cycle times and not have to worry about not having enough power to properly power the 22 gpm pump. I would like to do the 22 gpm though as I have been talking this thing up to my brother for a while...lol.

HCB7077

New Member

I think surpluscenter will say what the min hp will be for their pumps. Another suggestion of mine ( for what it's worth ) if you end up buying a valve make sure to get one withan adjustable pressure relief and 3/4" work ports since your looking for speed. My valve I got is a fixed pressure relief and 1/2" work ports which is actually restricting my flow ( according to a fluid power engineer at work )which slows the speed of my ram ( but beggars can't be choosers ) I got my cylinder and valve for free from a friend and I have decided that it is fast enough that it is not worth $100 for a better valve. I know I have probably under $700 in mine, I got the 4 cyl Wisconsin for free also but it took me about a year of gathering as many parts as I could for free.

Best of luck on your build and I hope you will be as pleased with your machine as I have been with mine.

Best of luck on your build and I hope you will be as pleased with your machine as I have been with mine.

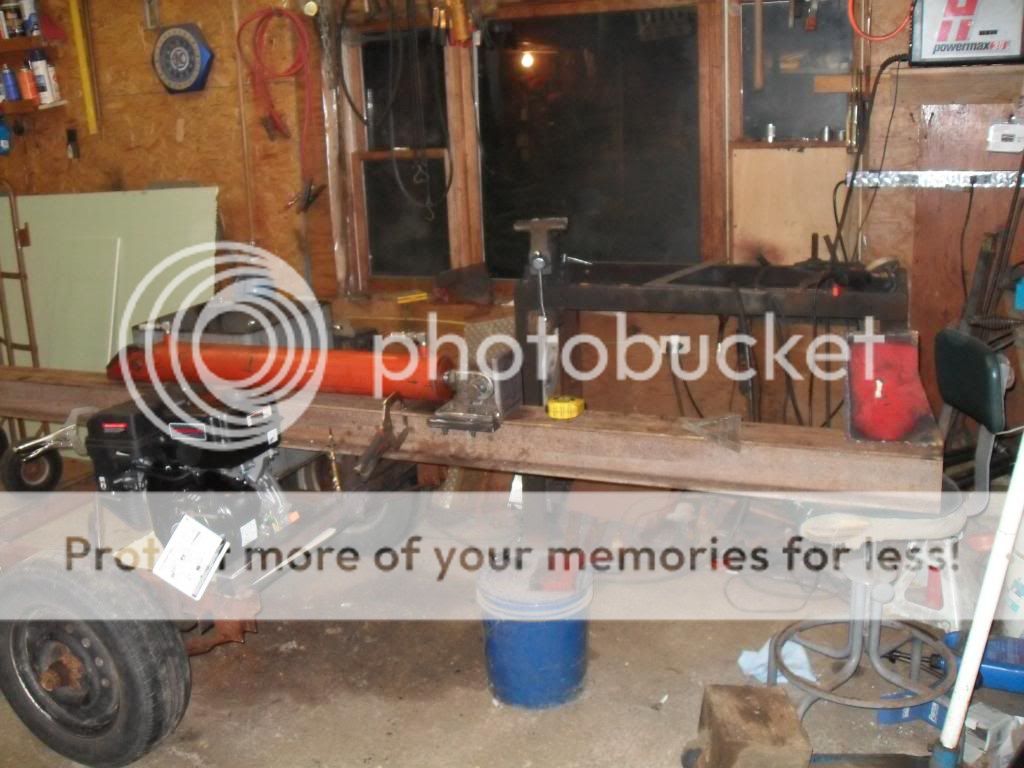

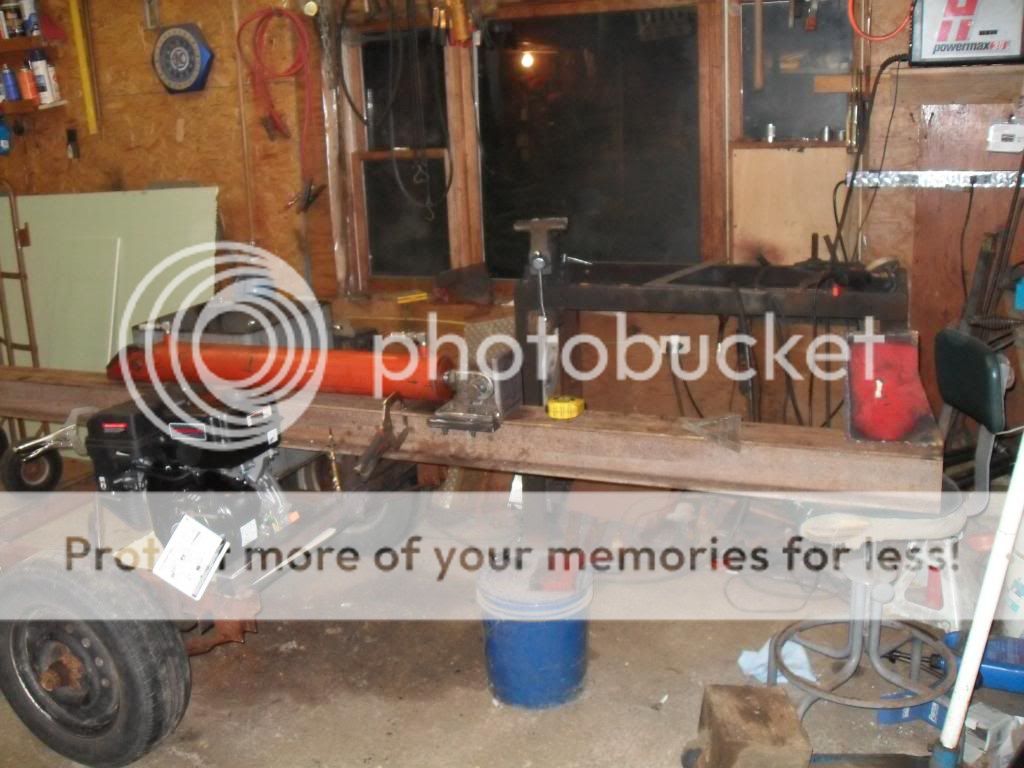

As promised, a couple of pictures of the mock up.

OK so it's been a while since I have made any headway on my splitter but got a couple of things done to it today. I put the bungs in the hydraulic tank and welded the cover on, go the holes drilled for the engine and made a receiver on the beam in the front to hold the jack. I will try and take some pics of that part tomorrow.

I did get my pump and adapter , now I just need to get my valve. Progress is slow as money allows. LOL

Oh yeah, i almost forgot, I have the beam cut to length now too.

I did get my pump and adapter , now I just need to get my valve. Progress is slow as money allows. LOL

Oh yeah, i almost forgot, I have the beam cut to length now too.

Similar threads

- Replies

- 3

- Views

- 404

- Replies

- 17

- Views

- 3K

- Replies

- 34

- Views

- 1K

- Replies

- 3

- Views

- 945

- Replies

- 0

- Views

- 892