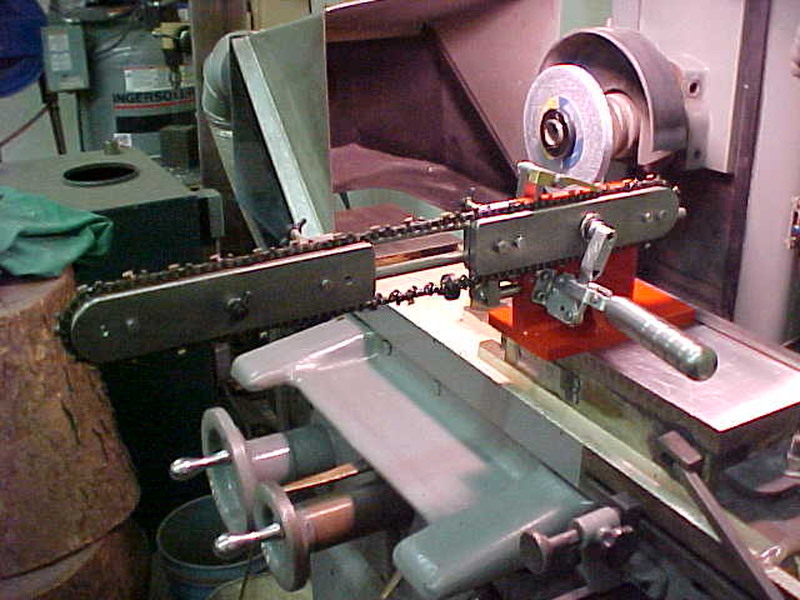

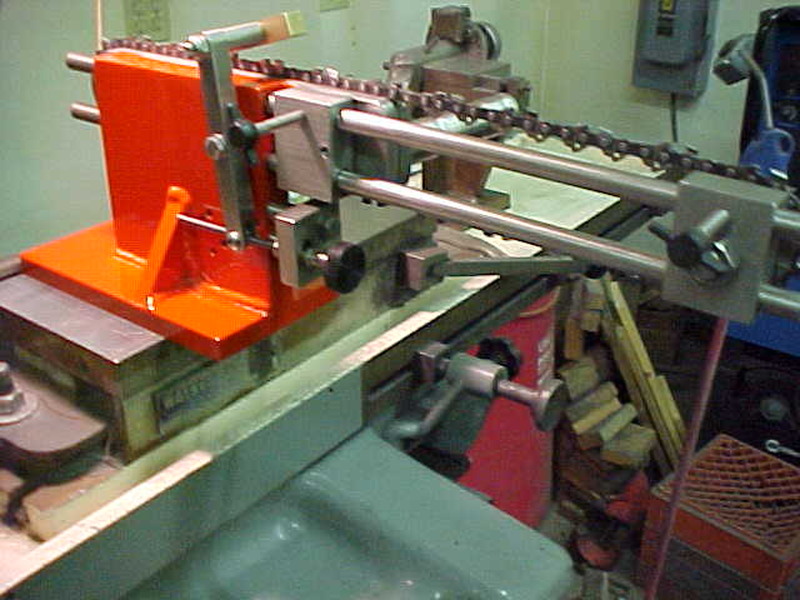

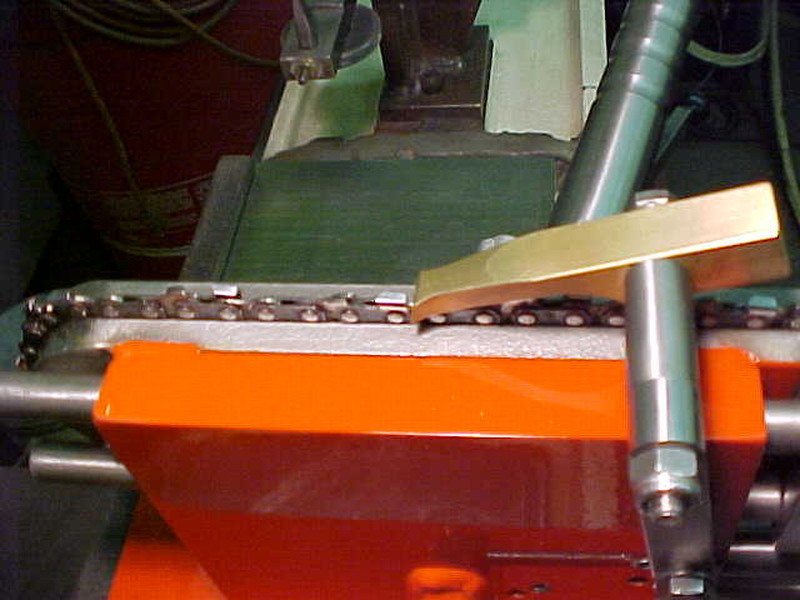

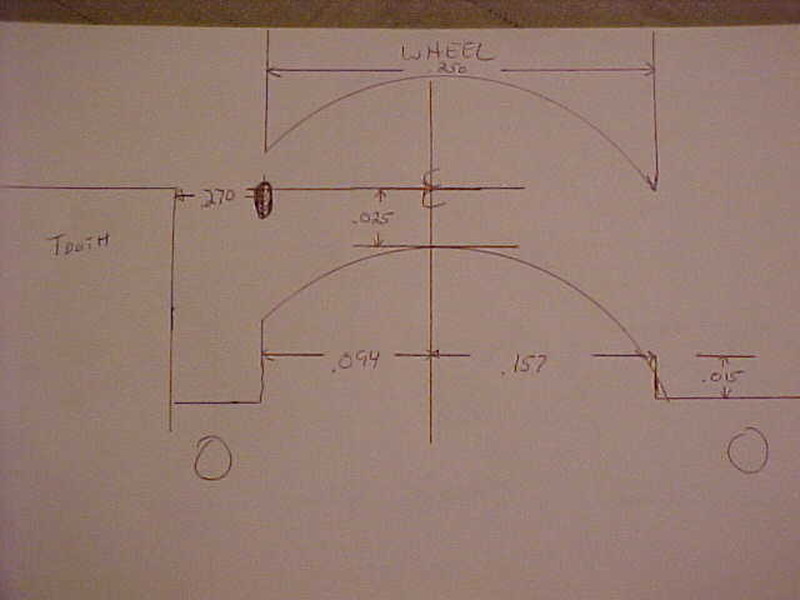

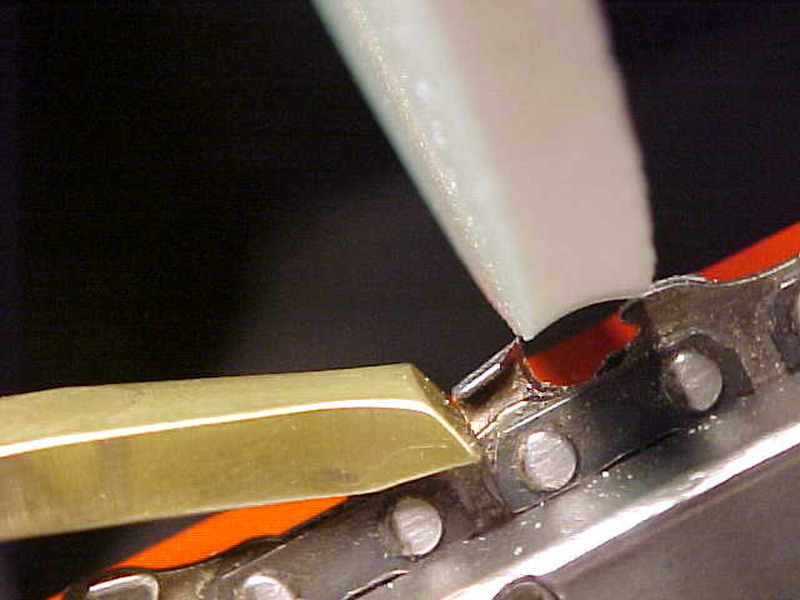

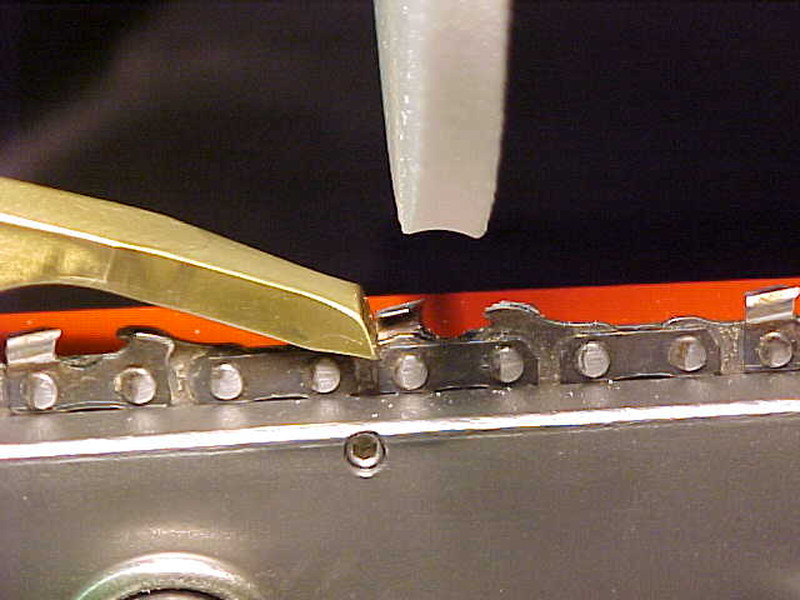

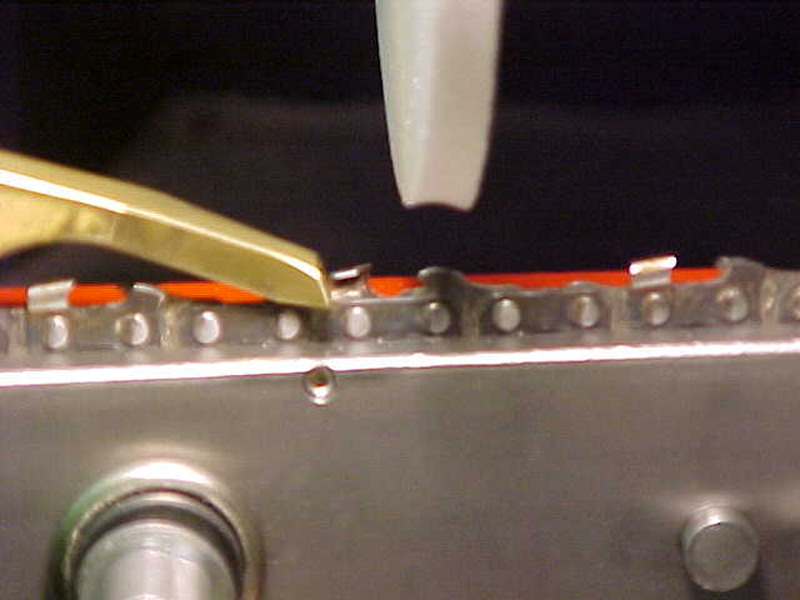

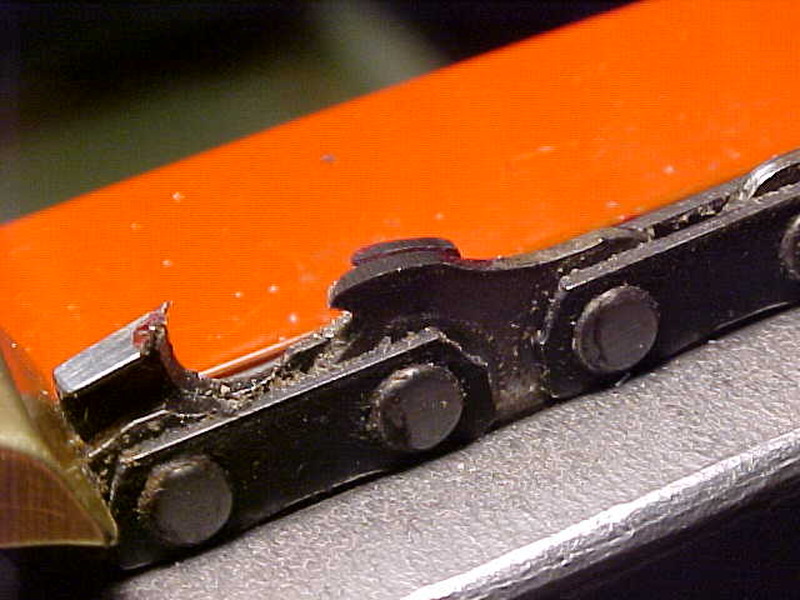

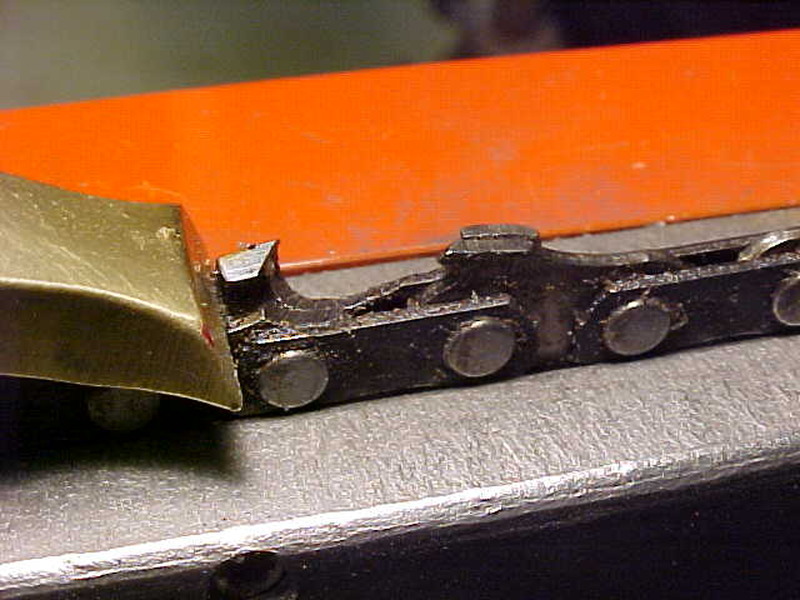

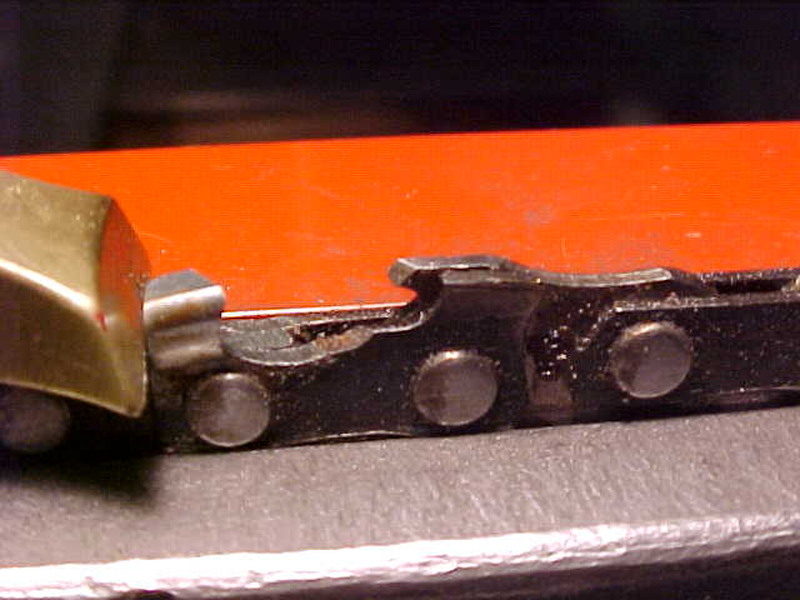

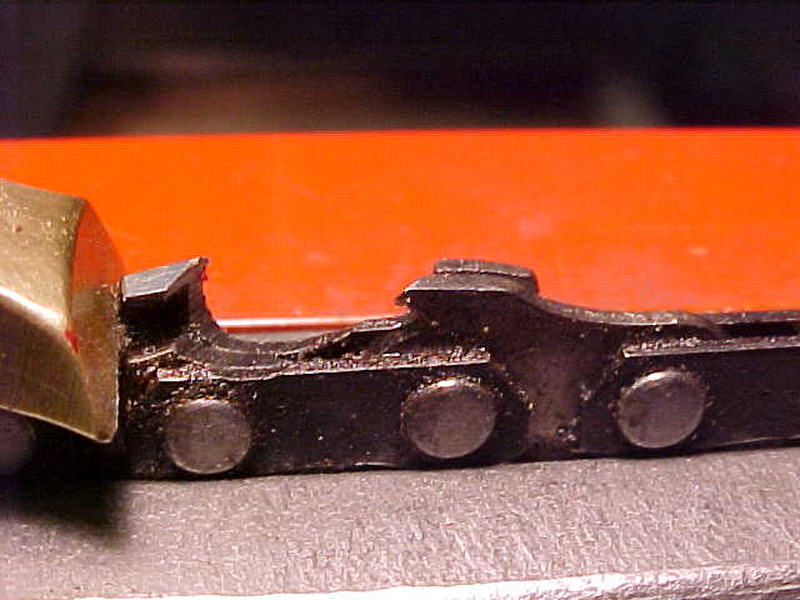

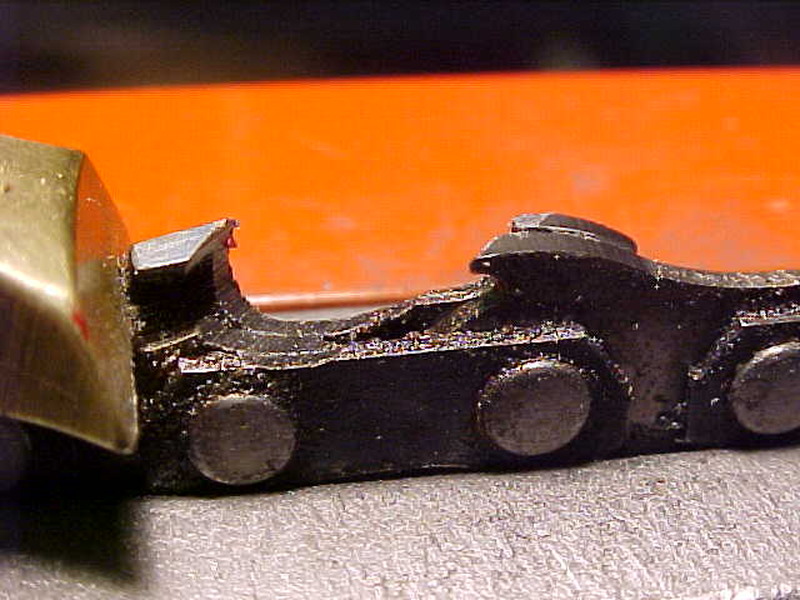

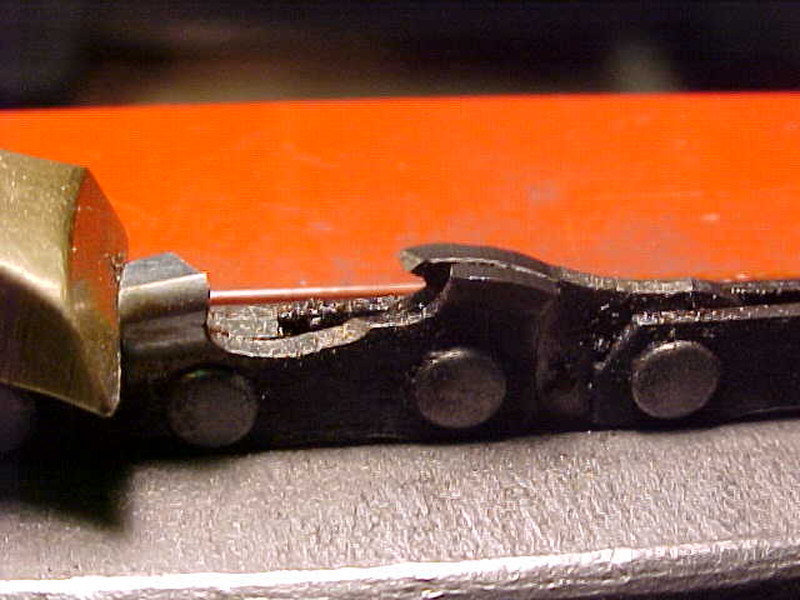

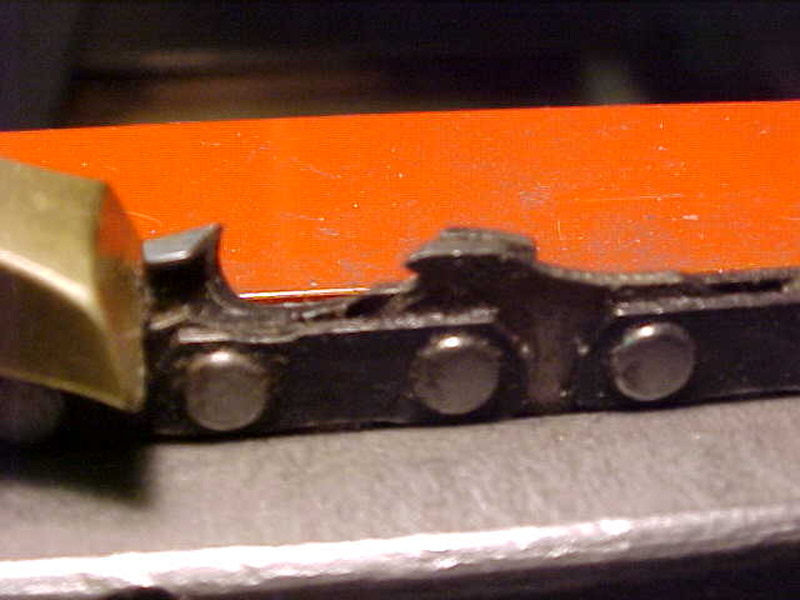

Here it is after. Quite a difference. It was VERY telling on how much it varied as I went around the chain and did them all. Some didn't touch so when I put it back on I don't know how much of a change I'll see. This chain has been sharpened a lot. I need to get a first time sharpened chain that had hard damage or something to where a lot of the tooth was take down at once.

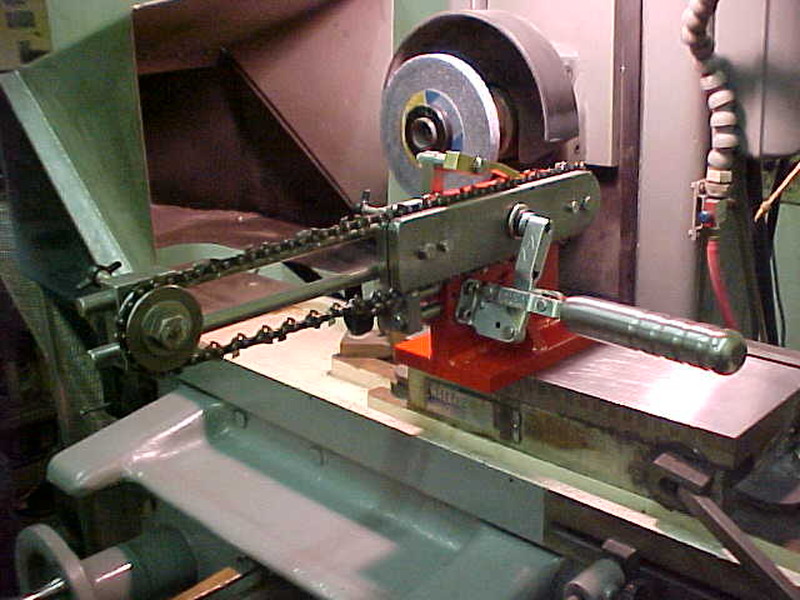

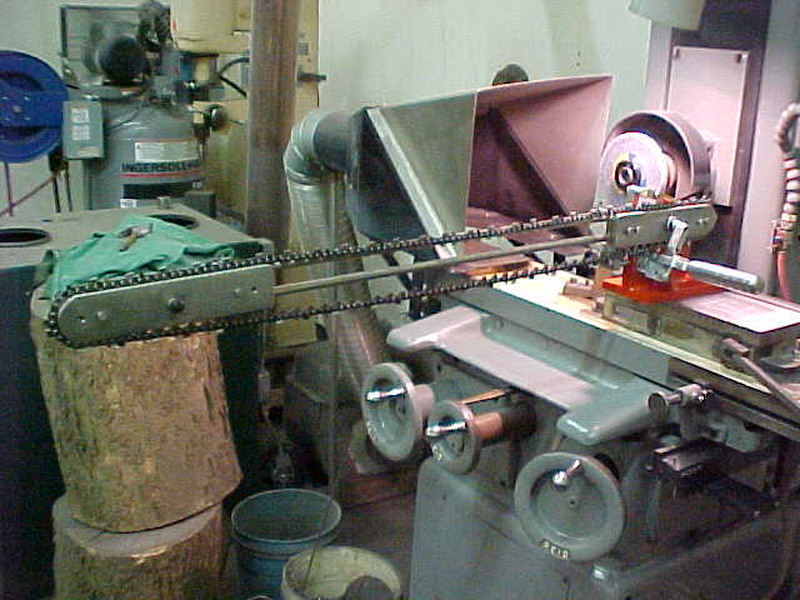

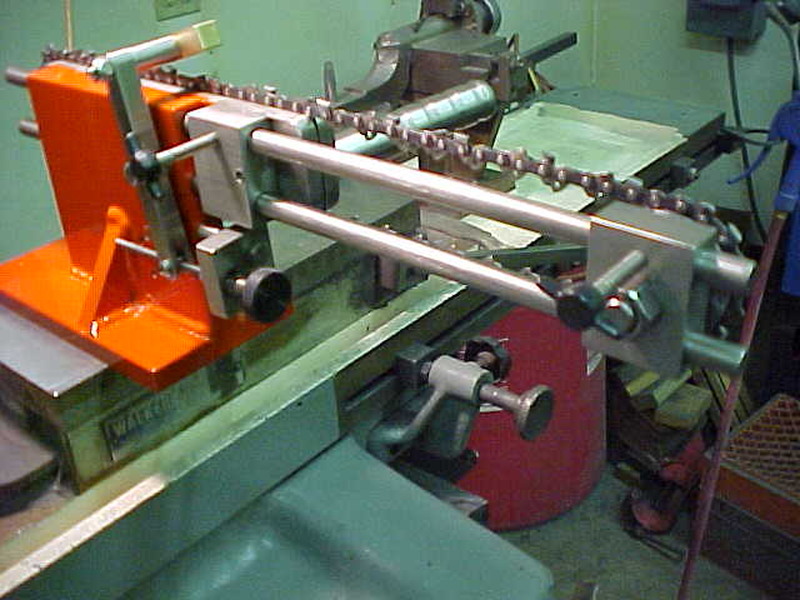

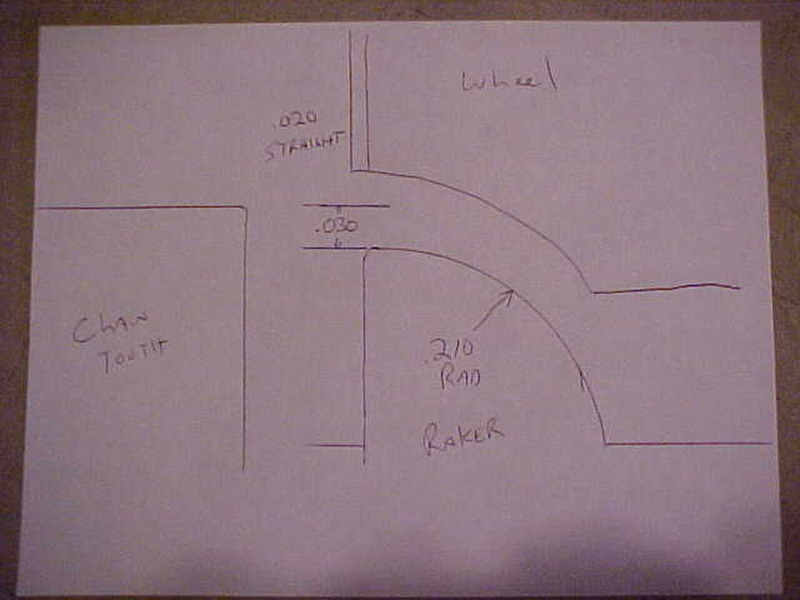

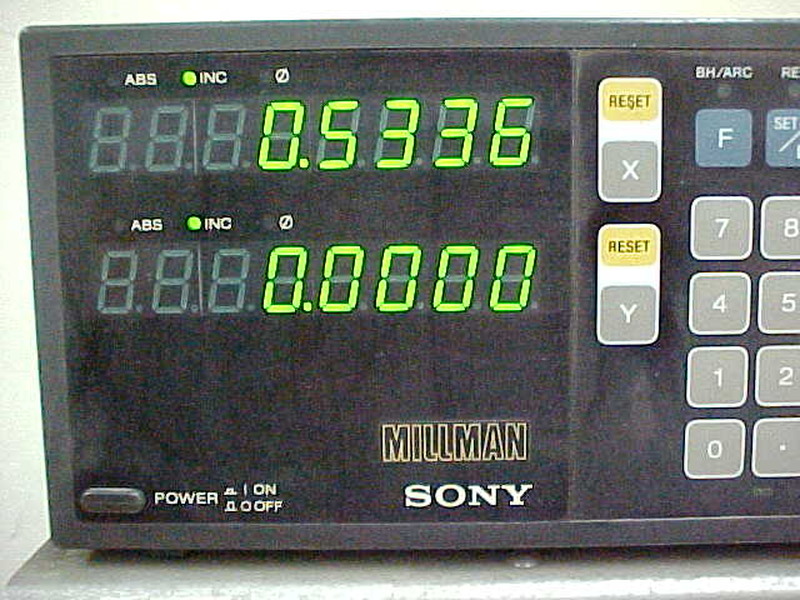

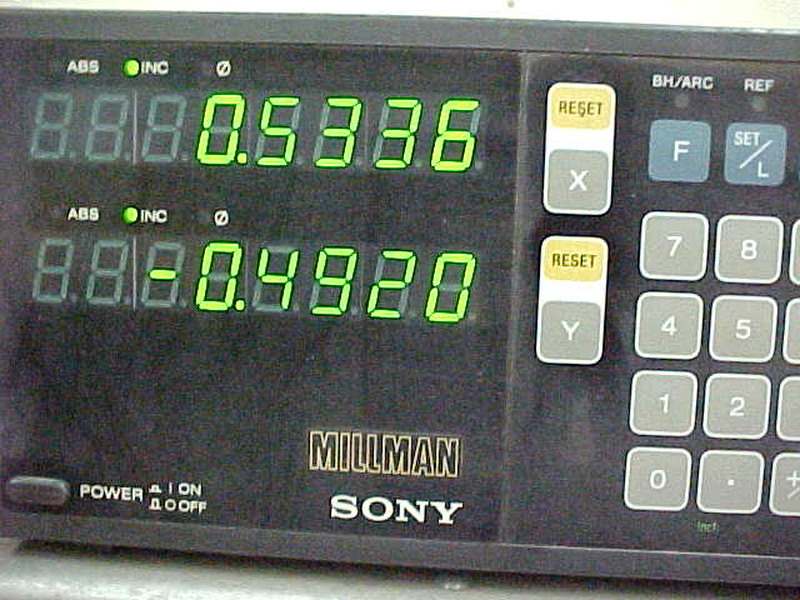

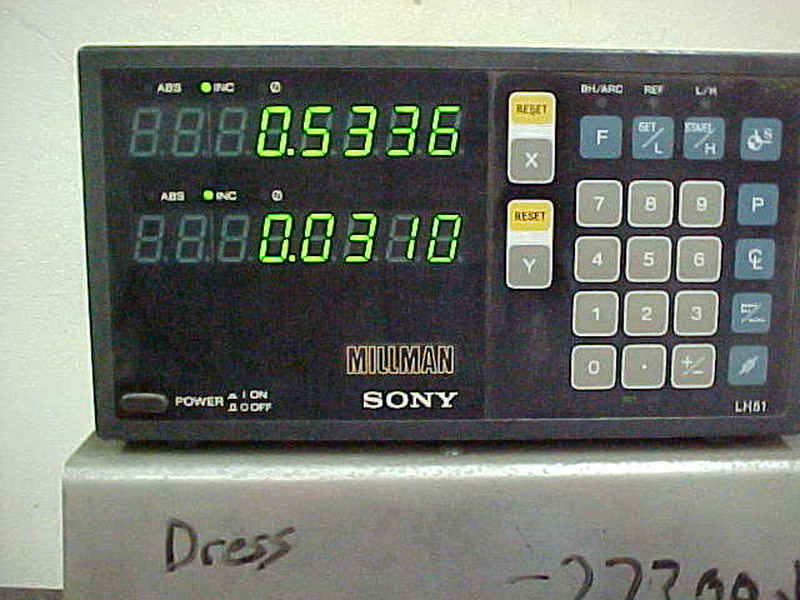

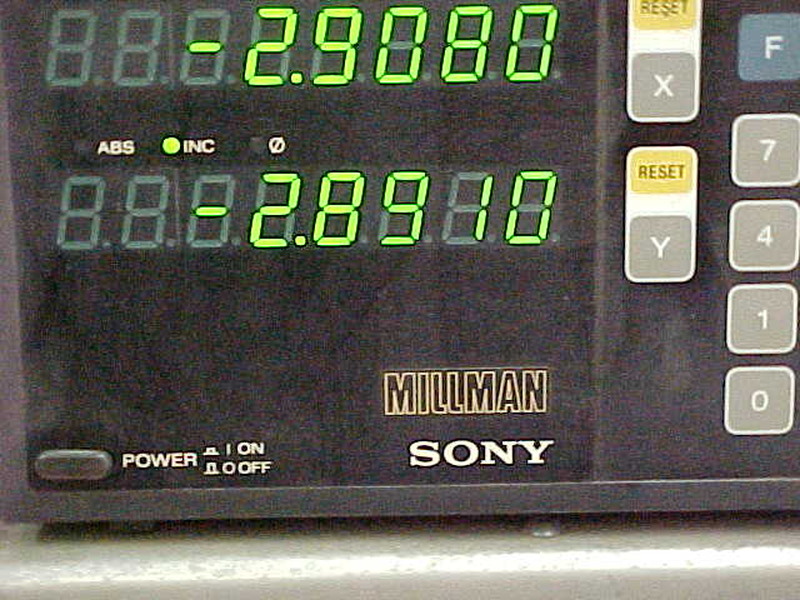

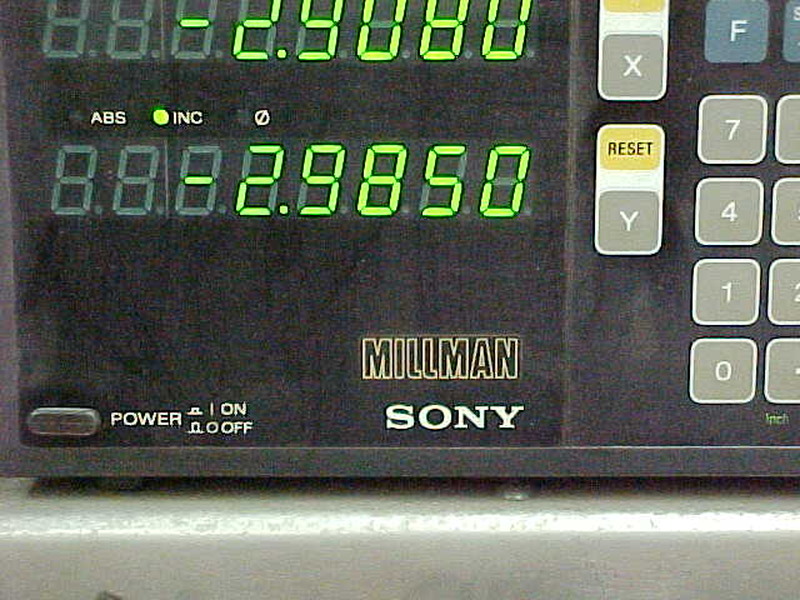

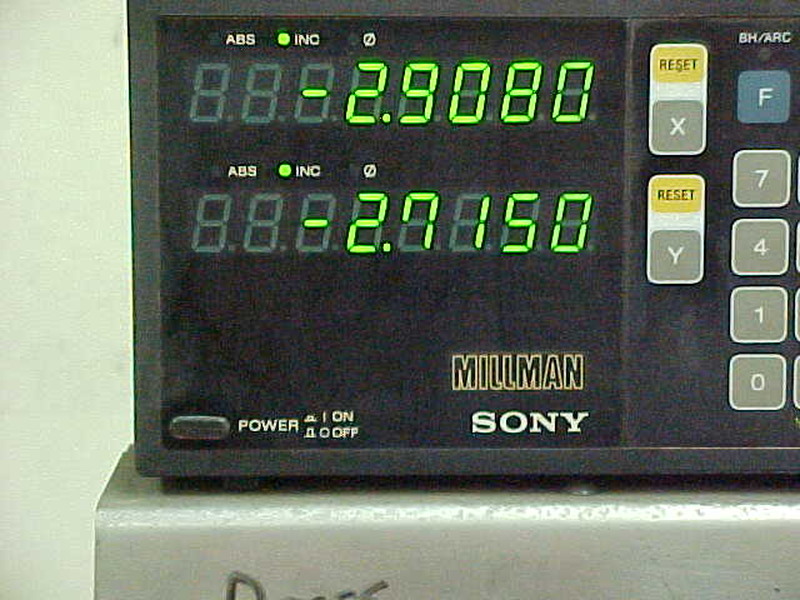

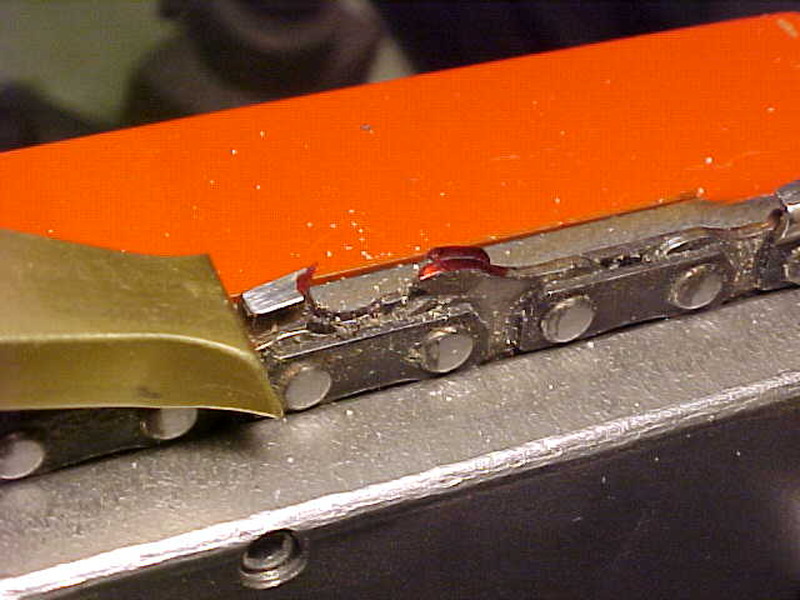

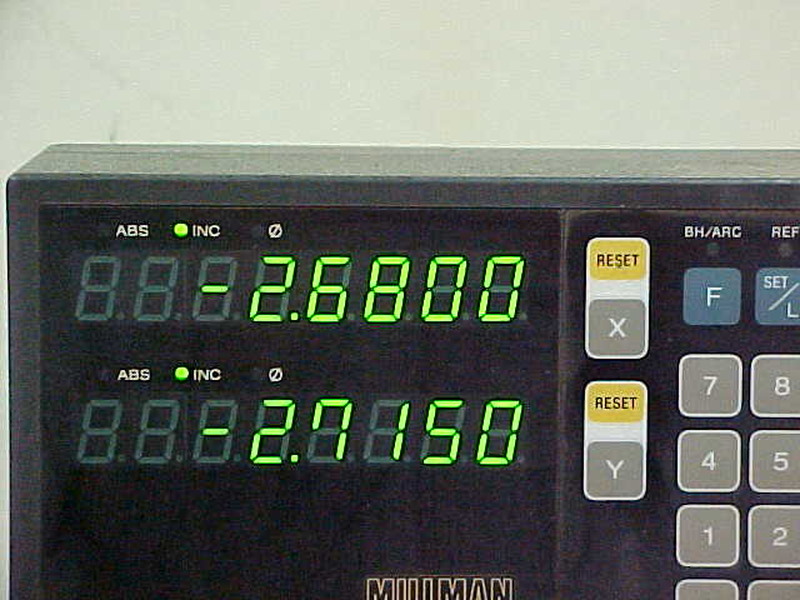

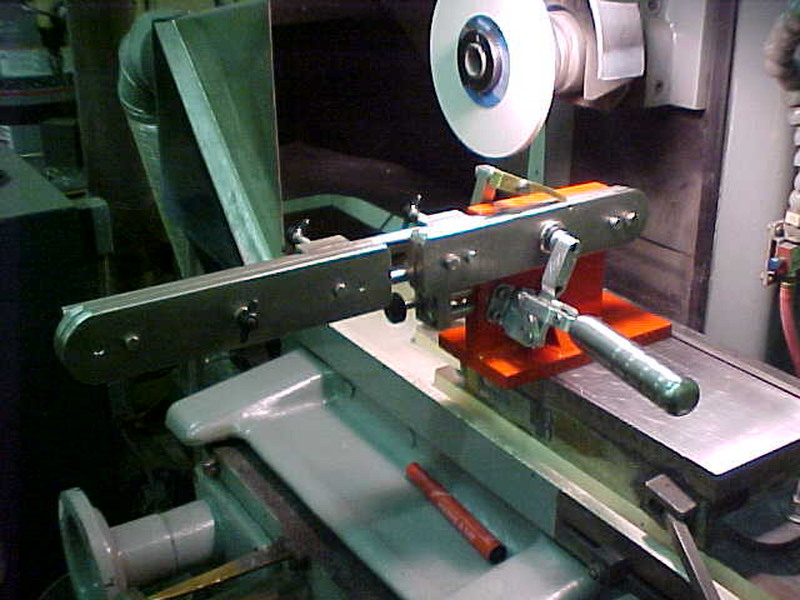

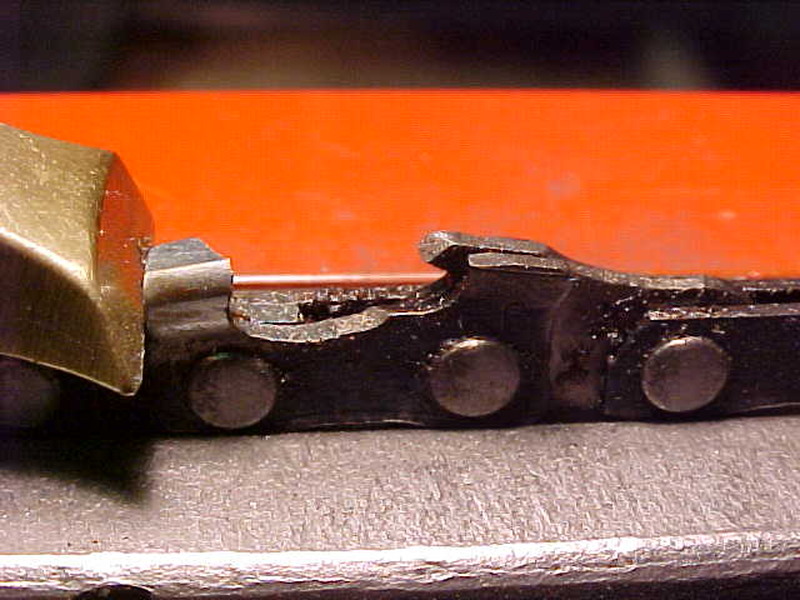

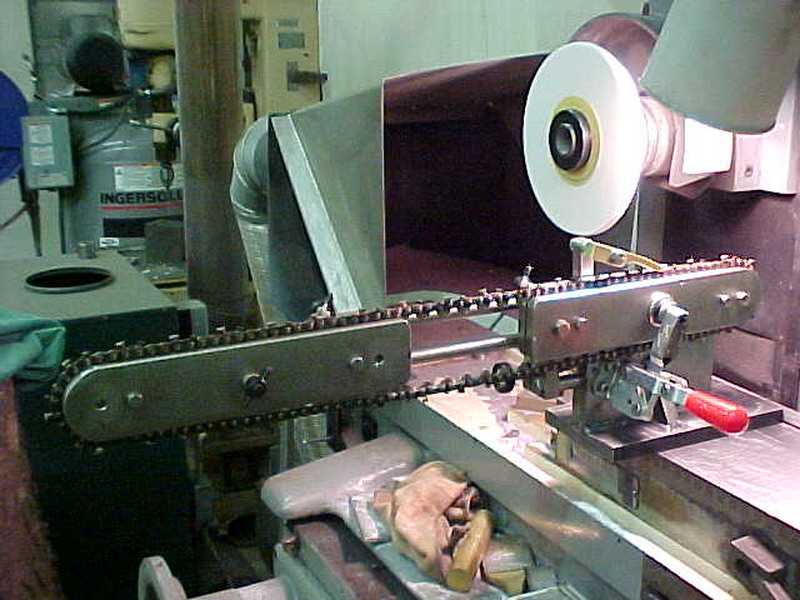

This is the set up for an 18" chain. Went really smoothly

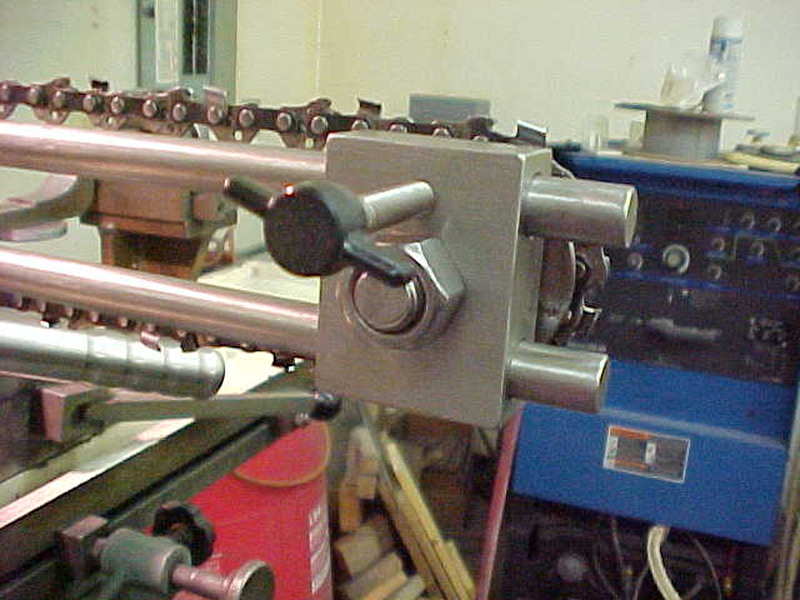

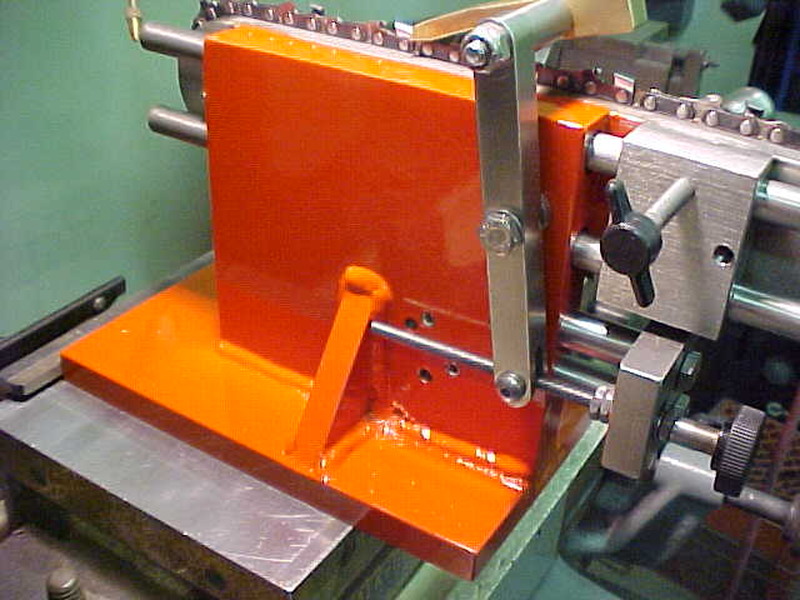

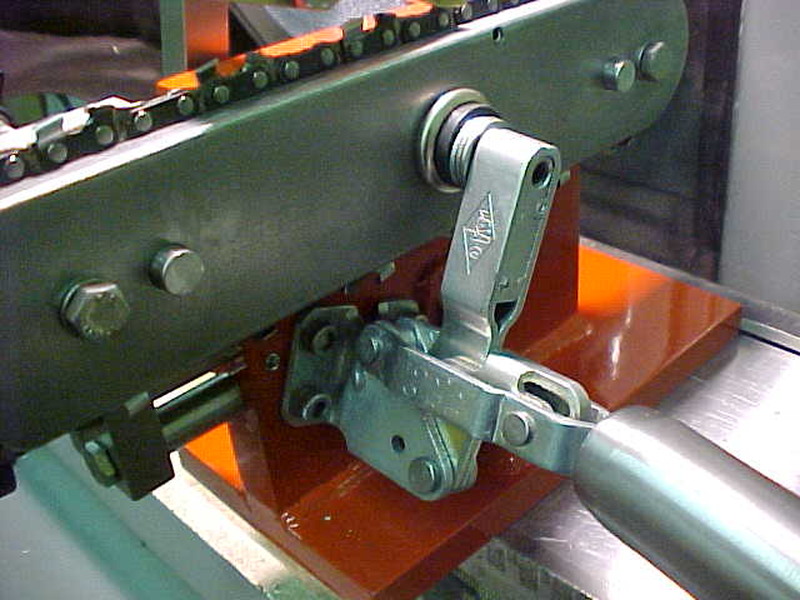

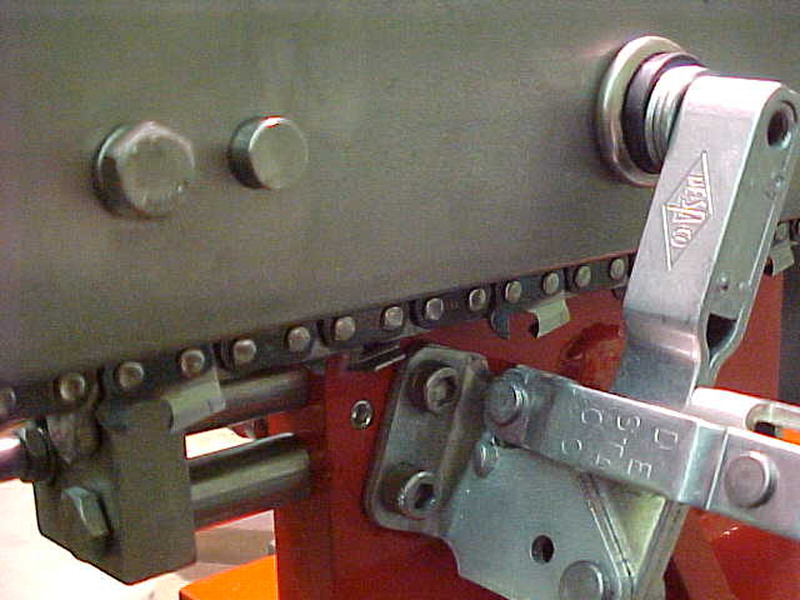

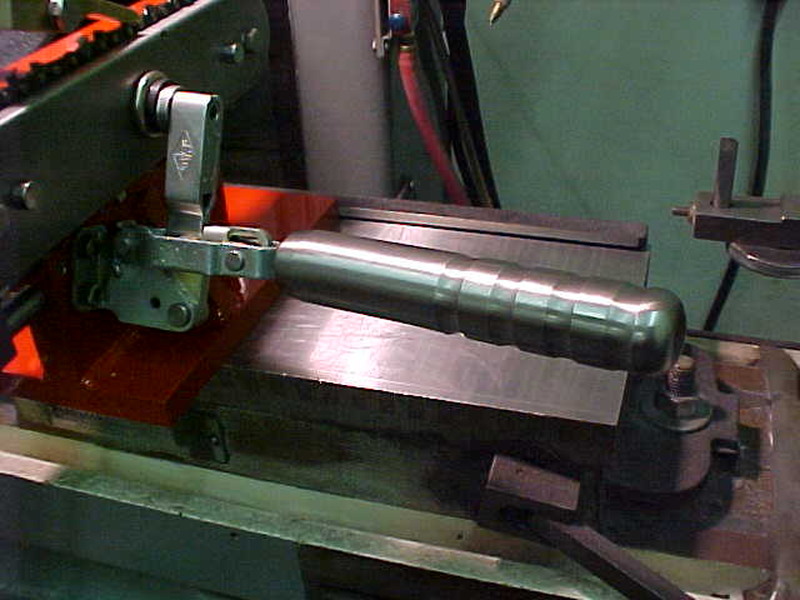

Decided I wanted a little bigger handle for the snap clamp. the clamps do wear out so I'll make the handle so I can reuse it. Drilling it here to slip over the rectangular shaped end.

Slipped it over that and marked where my fingers normally would be. I marked those and will recess some there for a grooved type grip.

Drilled and tapped for a couple set screws to hold it on and rounded /angled the ends as well.

Handle makes it have a nicer feel too.

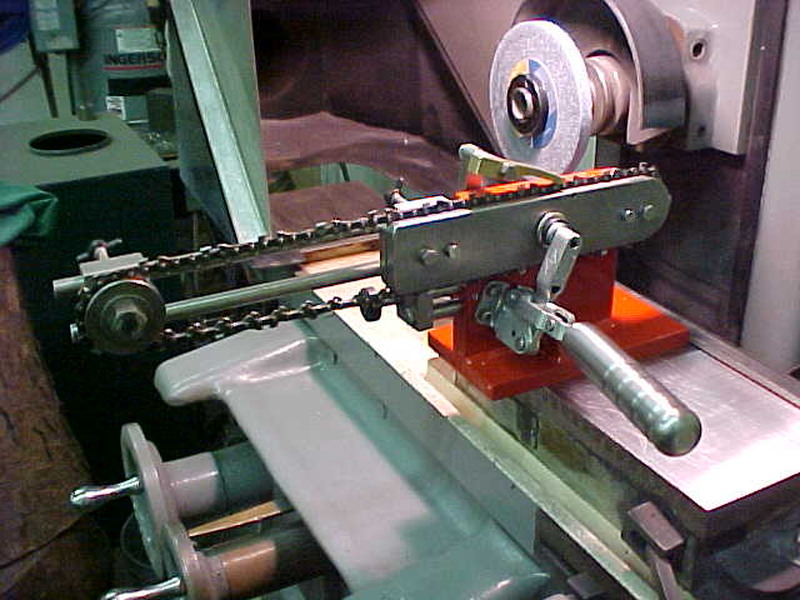

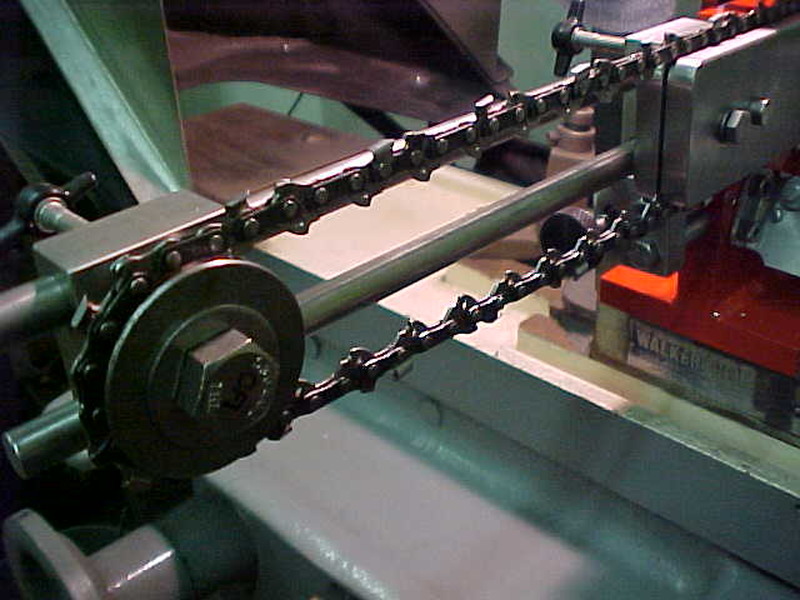

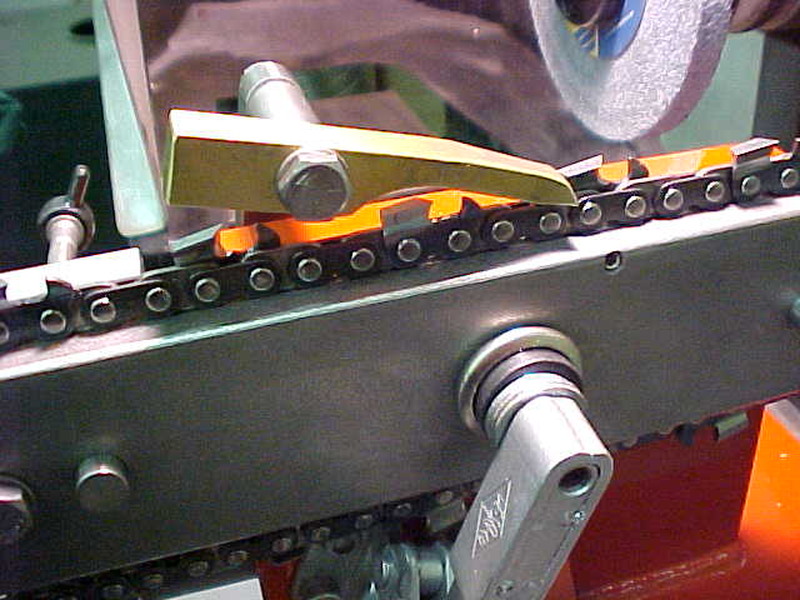

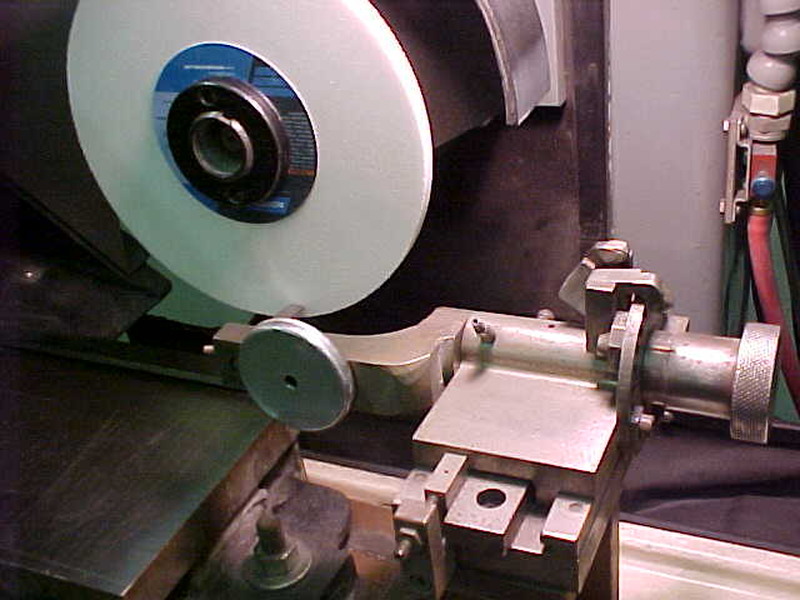

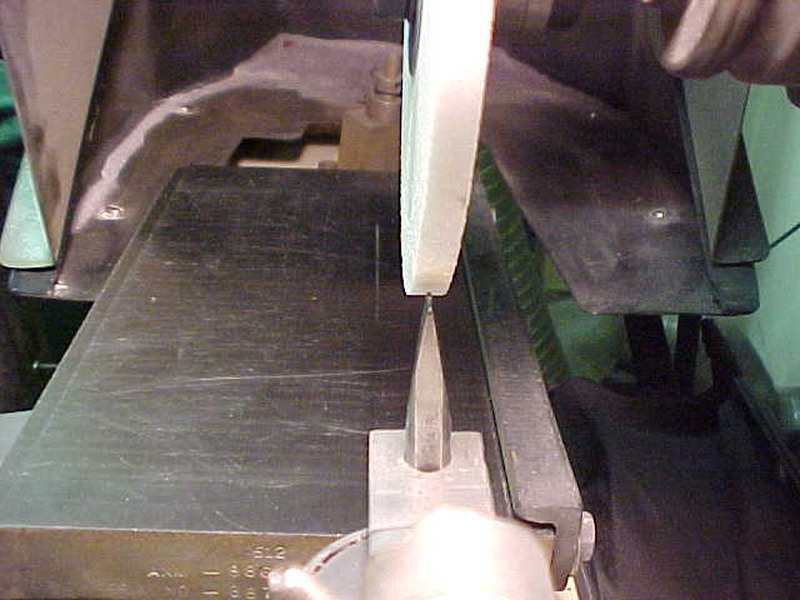

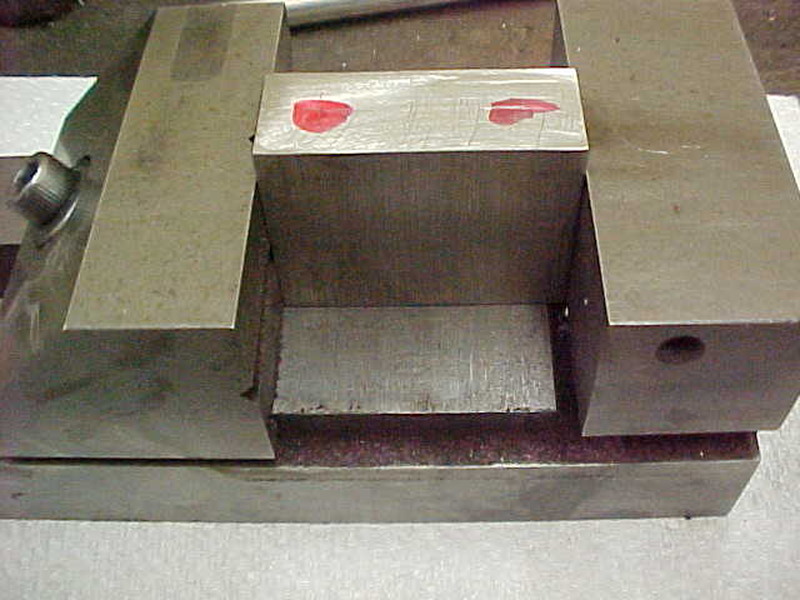

For short loops I thought I'd just let them hang but it is so much nicer to have them taught ads it indexes easier. Going to make up a roller assembly for those. Started by duplicating another slide block from the same bar as before.

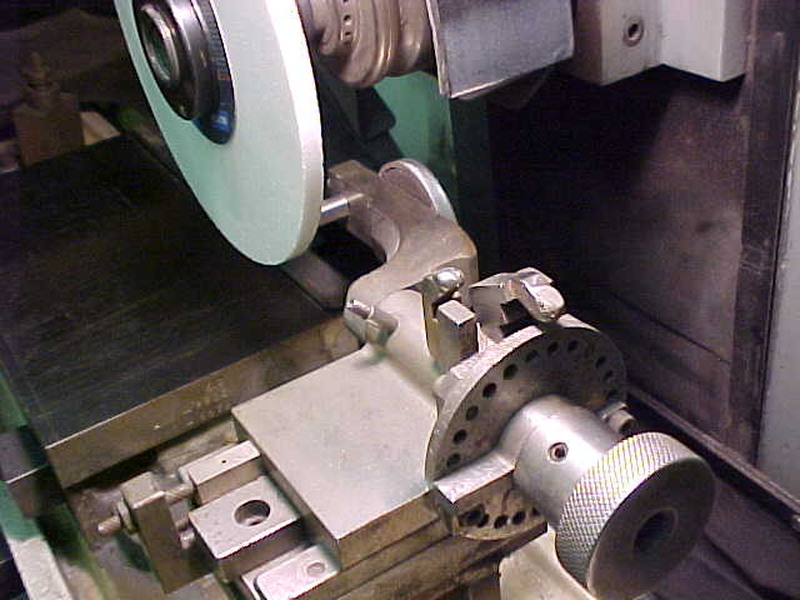

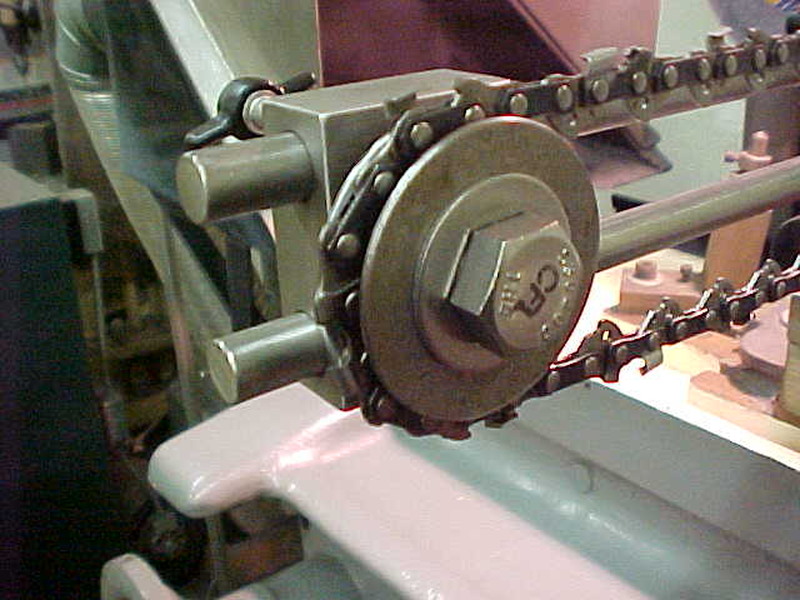

Found an old belt pulley with a .500 center hole. I drilled and tapped for a slide bar hold, then drilled and tapped for a 1/2 course thread. This way I can thread it in and use a single nut to lock it on, allowing the pulley to spin freely.

Works like a charm