Mastermind

Work Saw Specialist

I try to keep the same entry angles that the factory designers had. Sometimes when raising the transfers a lot, that is tough to do. Also, you have to be careful not to cut thru the top.

I try to keep the same entry angles that the factory designers had. Sometimes when raising the transfers a lot, that is tough to do. Also, you have to be careful not to cut thru the top.

Measure three times, check twice, cut onceFinally got around to dropping off my cylinder to my machinist buddy. Originally it had .030 off the squish and .030 off base. Now with the new piston( shorter on top and longer skirts) taking another .030 off squish and .044 off base, for a total of .074 off base, it should end up .026 squish.

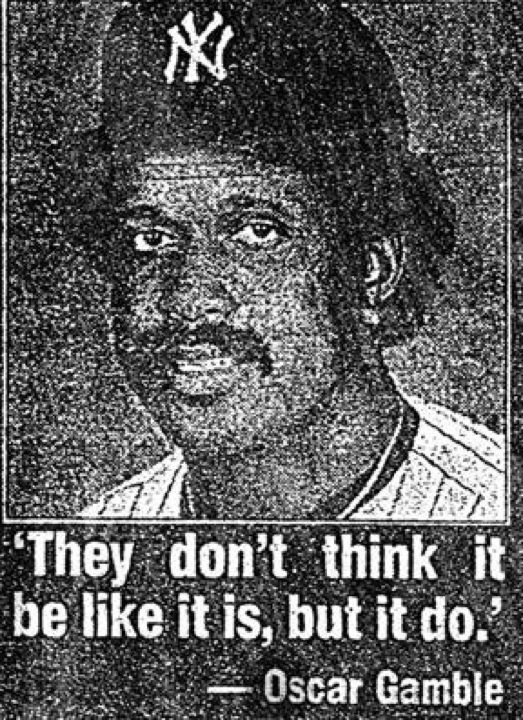

That makes sense right there!

Least he aint a Yank!!Maybe.

That guy sounds like a freakin hick though.

People sure payin a overalls wearin monkey with a grinder good money !! Lol!!! Must be doin somethin right?Maybe.

That guy sounds like a freakin hick though.

good straight foward info on the video. ThanksMaybe.

That guy sounds like a freakin hick though.

Most hicks have straight forward down to earth common sense thoughMaybe.

That guy sounds like a freakin hick though.

Hes not givin himself much credit here as many of us that have been beggin to pick his brain here alil today?Most hicks have straight forward down to earth common sense though

yes it did, big bore right?That pipe worked a lot better after I ported the old motor properly. lol

Enter your email address to join: