joeymt33

I bleed YELLOW!

Ron how long do you think it could have ran like this?

Hey Brian, did you receive the part I sent?

Ron how long do you think it could have ran like this?

Ron how long do you think it could have ran like this?

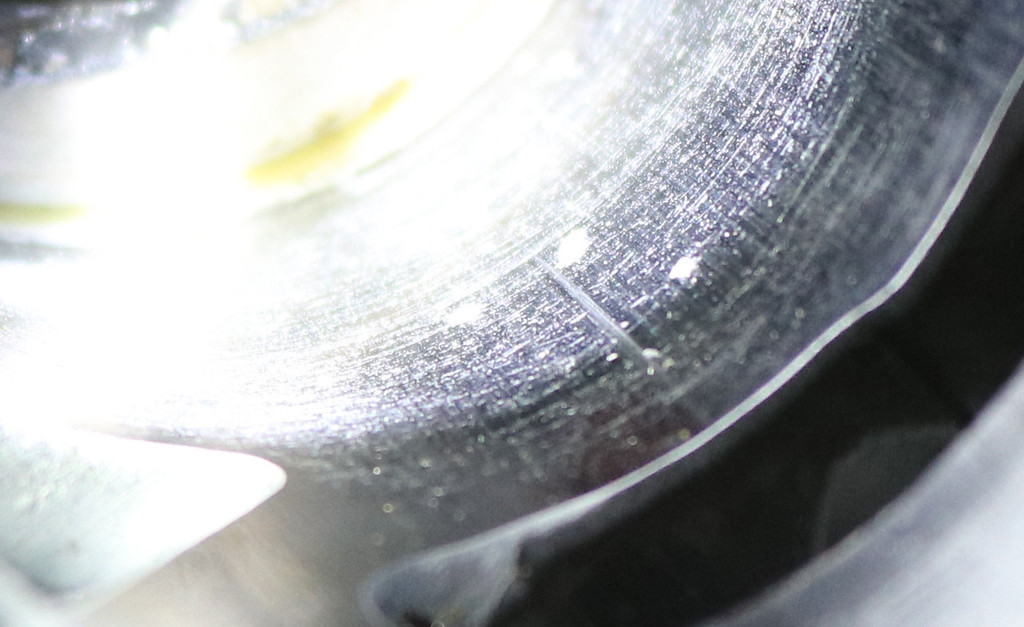

Rob I use US Chrome to replate my cylinders. If you want you can send it to me and I can look at it and see if it can be salvaged. If not I can have it replated for you. I have an A cylinder right now on the shelve that I just got back from them and they done a wonderful job. Just not had the time to swap the cylinder out with the B cylinder I have on it now that is not bad but a little loose. I am going to send the old one to be replated after I find the time to swap the cylinders.

Brian

Around 190.00 to around 210.00

Brian

Yes I did thank you! Haven't had time to mess with yet. I will this weekend. Part time saw repair, part janitor, and full time farm hand. LolHey Brian, did you receive the part I sent?

I've never heard of a cylinder (on a saw not used for racing) burning through in area lacking plating..., especially below the ports. Additional flaking occurring, possibly (but not necessarily imminent, either). Bare aluminum cylinders with plated pistons were common not that many years ago. I may be all wet, but have never worried about small areas of missing plating.

I would not use acid to clean up any cylinder with questionable plating or aluminum exposure. It will eat any exposed aluminum and destroy an otherwise perfectly salvageable cylinder that may only have some incidental streaking or gouges along with the typical aluminum x-fer that can be easily removed by any number of simple methods. Traditional honing should be avoided as it is too aggressive. 220 grit paper would be a good start to see what you can remove easily just using a drill with a split mandrel for the paper. You may be surprised at how well it cleans up while also putting a much more positive (and economical!) spin on the matter.