mweba

Addicted to ArboristSite

What was the stihl at the end??? It was pretty impressive!

Tree monkey's 026. Impressive is not the word, more like ridiculous.

What was the stihl at the end??? It was pretty impressive!

Very impressive work! Man is only limited by his imagination.

Now, make room for a 372 topend:msp_thumbsup:

Nice build!

Okay next build, 390 on a 372... :msp_ohmy:

That's actually not that hard to do. Would be fun though.

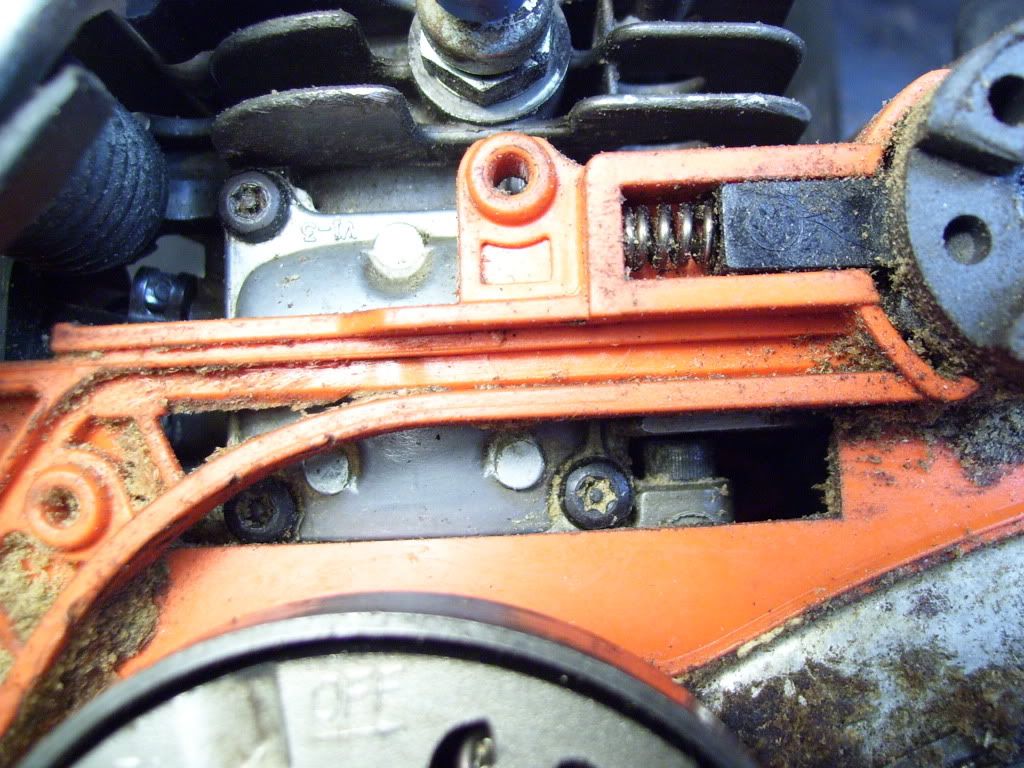

Finished adapter assembled in saw.

it's about time you get this posted:msp_tongue:

can you cut a clamshell cylinder?

Enter your email address to join: